Molten iron splash-proof energy-saving device for mining and metallurgy machining

An energy-saving device and molten iron technology, applied in the field of mining and metallurgy processing, can solve problems such as punching out of the mold, waste of molten iron, and inability to enter the molten iron normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

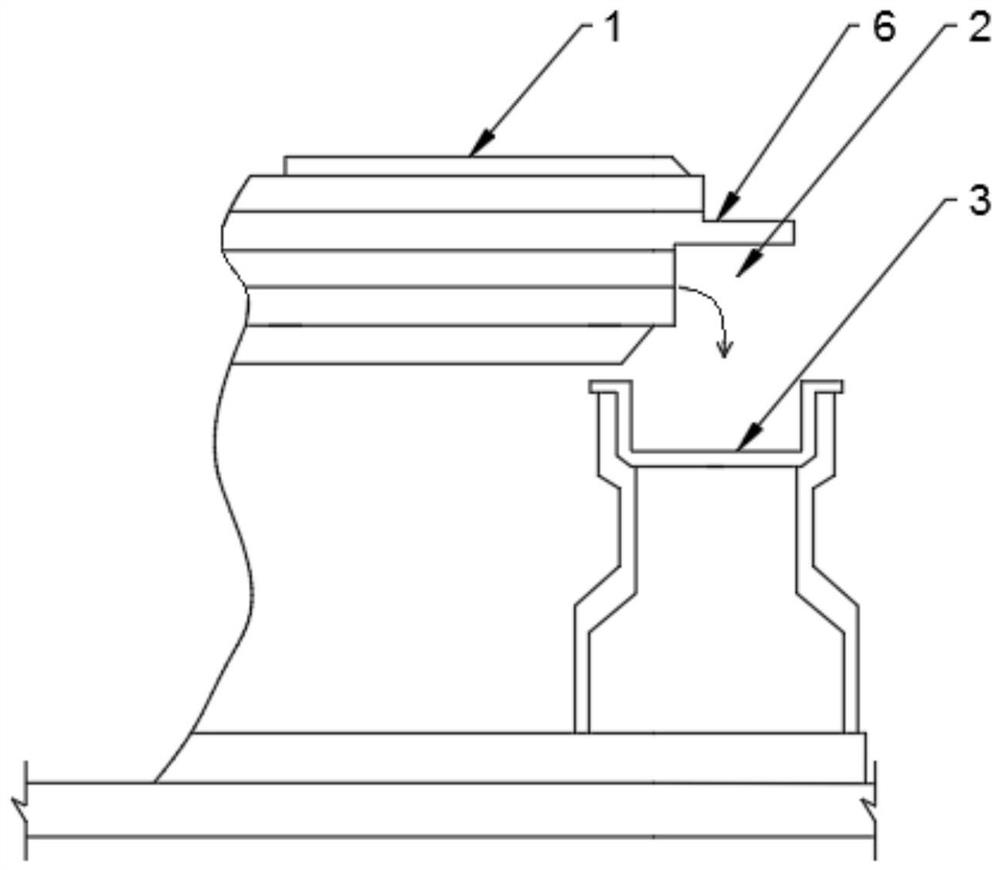

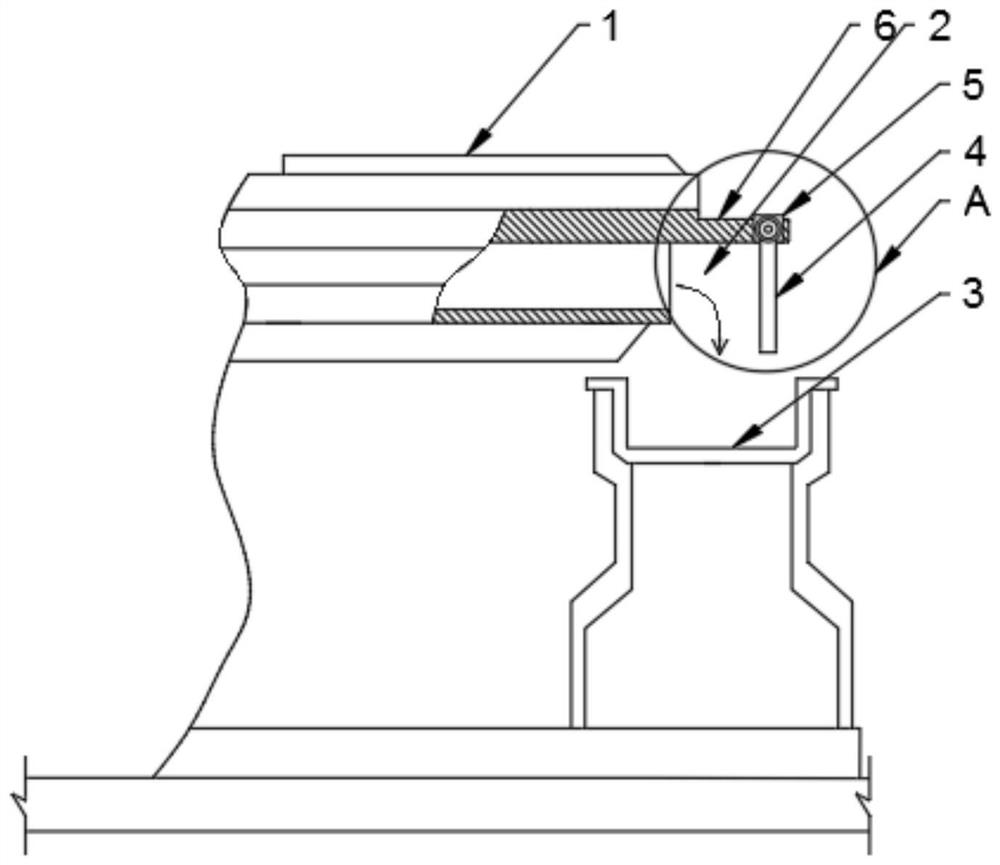

[0038] An anti-splash energy-saving device for molten iron in mining and metallurgy processing, comprising a molten iron tank 1 with a molten iron inlet 2 and a mold 3, the molten iron tank 1 where the molten iron inlet 2 is located is provided with an articulated plate 6, and the articulated plate 6 is There is a baffle 4 located on the right side of the molten iron inlet 2, and the longitudinal projection of the baffle 4 is located in the mold 3; the left side of the baffle 4 is provided with an anti-sticking coating.

[0039] In this embodiment, a baffle plate 4 is arranged on the molten iron tank 1 to buffer the impact of the molten iron.

[0040] as attached Figure 2-3 As shown, the present invention provides an energy-saving device for preventing splashing of molten iron in mining and metallurgy processing, which includes a molten iron tank 1 with a molten iron inlet 2 and a mold 3. The mold 3 is located below the molten iron inlet 2 to facilitate receiving molten iron....

Embodiment 2

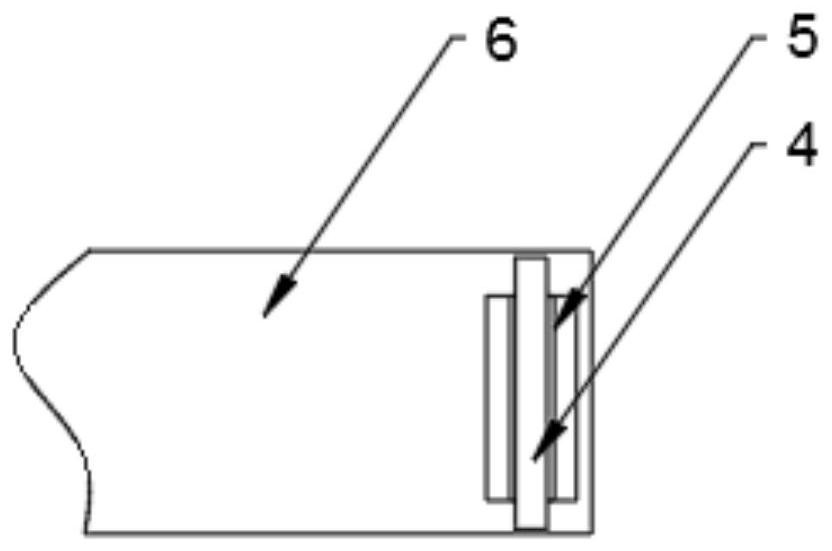

[0068] An anti-splash energy-saving device for molten iron in mining and metallurgy processing, comprising a molten iron tank 1 with a molten iron inlet 2 and a mold 3, the mold 3 is provided with a baffle 4 on the right side of the molten iron inlet 2, and the left side of the baffle 4 The longitudinal projection of the side is located in the mold 3; the left side of the baffle 4 is provided with an anti-sticking coating.

[0069] As another usage mode of the present invention, the baffle plate 4 is also used in the anti-splash mode, but it is arranged on the mold 3 .

[0070] as attached Figure 6 As shown, a baffle plate 4 is installed on the top surface of the main body on the right side of the mold 3 and fixed by bolts. But in order for molten iron to enter normally, the longitudinal projection of the left side of the baffle plate 4 needs to be located in the mold 3 .

[0071] Similar to Embodiment 1, the left side of the baffle plate 4 is provided with an anti-sticking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com