Knee joint brace extruding and recycling device

A recycling device and knee joint technology, applied in the field of medicine, can solve the problems of low processing production efficiency, labor and time-consuming, etc., and achieve the effects of improving recycling production efficiency, saving manpower, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

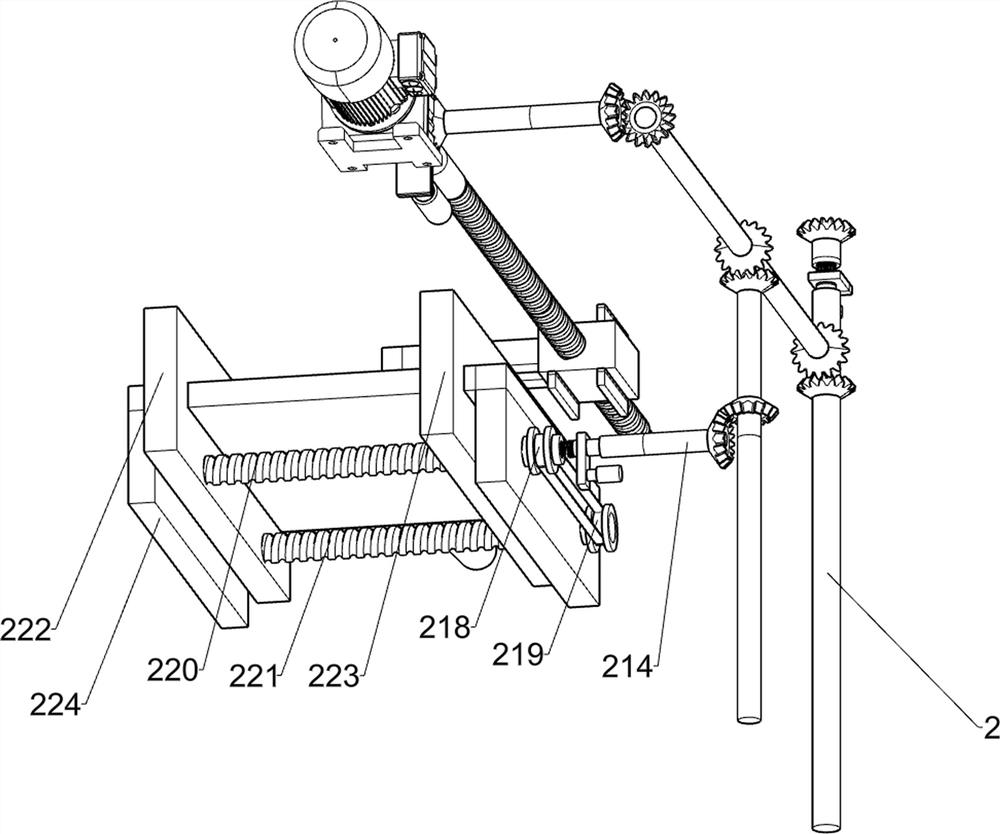

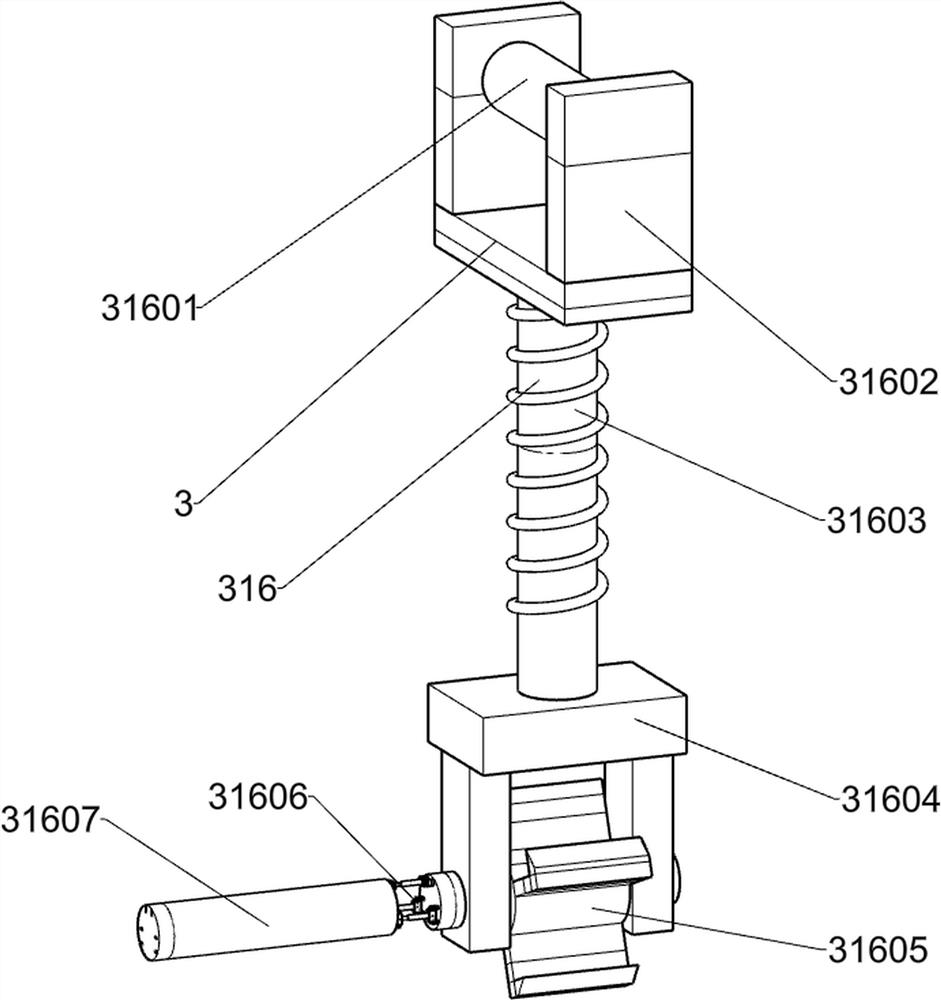

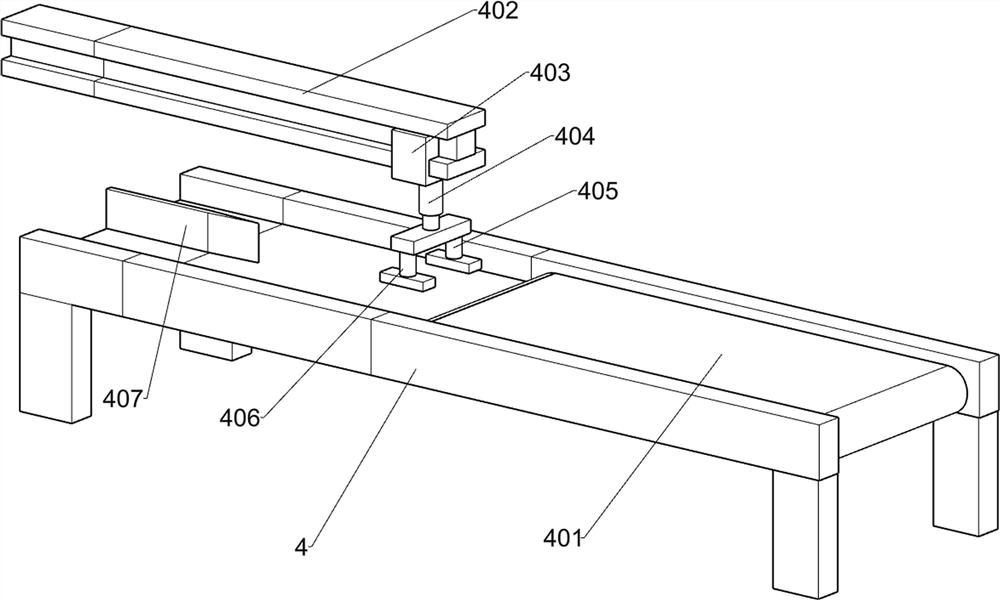

[0030] A knee brace extrusion recovery device, such as Figure 1-10 As shown, it includes a base plate assembly 1, a feed expansion unit 2, a disassembly unit 3, a cutting and separation unit 4 and a control panel 5; the base plate assembly 1 is connected with the feed expansion unit 2; the base plate assembly 1 is connected with the disassembly unit 3 connection; the bottom plate assembly 1 is connected with the cutting and separating unit 4; the bottom plate assembly 1 is connected with the control panel 5;

[0031] When in use, first place a knee joint brace extrusion recovery device to the position to be used, then connect the external power supply, and start it through the control panel 5; The feeding and unfolding unit 2 on the component 1 makes the lower leg of the knee joint brace face forward, and then uses the feeding and unfolding unit 2 to squeeze out a certain space for the knee joint brace, and then unfolds the entire knee joint brace into a cylindrical shape, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com