Phosphorus-doped ultrathin hollow carbon nitride nanosphere catalyst for hydrogen production by efficient photocatalytic cracking of water

A technology of photocatalysis and carbon nitride, applied in the direction of physical/chemical process catalysts, hydrogen production, nitrogen compounds, etc. High charge recombination rate, etc., to achieve excellent activity and stability, cheap raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: According to Synthesis of SiO 2 template. The specific process is as follows: at 35°C, add 9 mL of ammonia water to a mixture of 150 mL of ethanol and 20 mL of deionized water, and stir magnetically for 1 hour to obtain a transparent precursor solution; under vigorous stirring, 11 mL of tetraethyl orthosilicate (TEOS ) was quickly added to the above precursor solution, and stood for 1h to obtain a white suspension; then, under vigorous stirring, 12.5mL tetraethyl orthosilicate (TEOS) and 6mL octadecyltrimethoxysilane (C 18 The mixed solution of TMOS) was added dropwise to the above suspension, and left to stand at room temperature for 3h; the resulting reaction solution was centrifuged, dried and roasted, and the roasting program was: the rate of 5 ° C / min was raised from room temperature to 550 ° C , kept warm for 6h, then cooled to room temperature to obtain a white solid; the above sample was acidified with 1M HCl solution at 80°C for 24h; finally ...

Embodiment 2

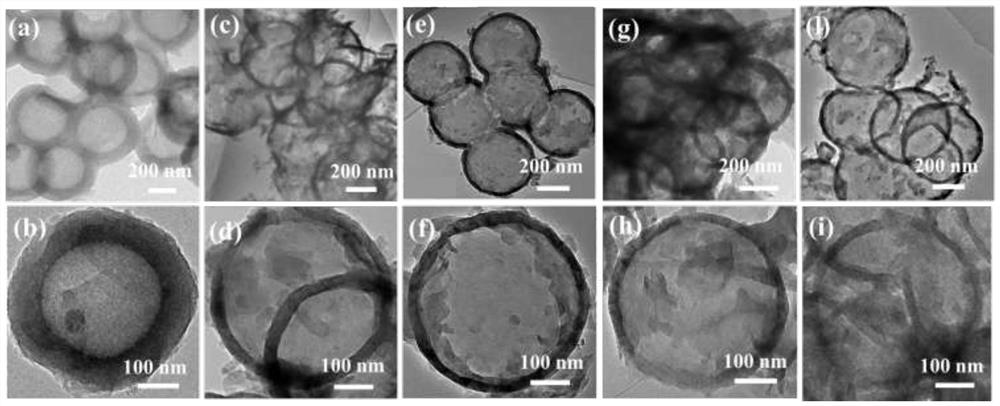

[0020] Example 2: Preparation of hollow carbon nitride nanospheres (H-CNS) by negative pressure ultrasonic method. The specific steps are as follows: 1gSiO 2 The template and 5 mL of cyanamide were mixed in a pressure-resistant bottle connected to a vacuum tube, and were subjected to ultrasonic treatment at 60 °C for 3 h and magnetic stirring at 80 °C for 3 h; then the sample was dried and calcined in a tube furnace, the roasting procedure was as follows: N 2 Under the atmosphere, the rate was raised from room temperature to 550 °C at a rate of 5 °C / min, kept for 2 hours, and finally cooled to room temperature to obtain a yellow sample; the ground sample was washed with 4M NH 4 HF 2 Treat at room temperature for 12h to remove SiO 2 Template; centrifuged and washed with distilled water and ethanol, dried at 60°C to obtain hollow carbon nitride nanospheres (H-CNS).

Embodiment 3

[0021] Example 3: A phosphorus-doped ultrathin hollow carbon nitride nanosphere (x wt% P / UH-CNS, x=0-10) catalyst was prepared by chemical vapor deposition. The specific steps are as follows: add 300mg of H-CNS powder, 3mg of iodine and a certain amount (1-10wt%) of purified red phosphorus into a quartz ampoule, vacuumize and seal it with an acetylene flame; Heating at a rate of 450°C for 4 hours; cooling at a rate of 1°C / min to 280°C and holding for 4 hours; then cooling slowly to room temperature at a rate of 0.2°C / min; 2 , washed with distilled water and ethanol, and dried at 60°C to obtain x wt% P / UH-CNS (x=0-10) catalyst.

[0022] The present invention has the characteristics of simple preparation process, cheap raw material price, high yield, regular and controllable product appearance, etc. The 2wt% P / UH-CNS catalyst prepared by the present invention exhibits excellent photocatalytic cracking water hydrogen production activity .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com