A selective wave-absorbing surface structure and its preparation method

A surface structure and selective technology, applied in the direction of antennas, electrical components, etc., can solve the problems of poor stealth effect and inability to completely filter out electromagnetic waves, so as to improve the effect of stealth and enhance the effect of selective absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

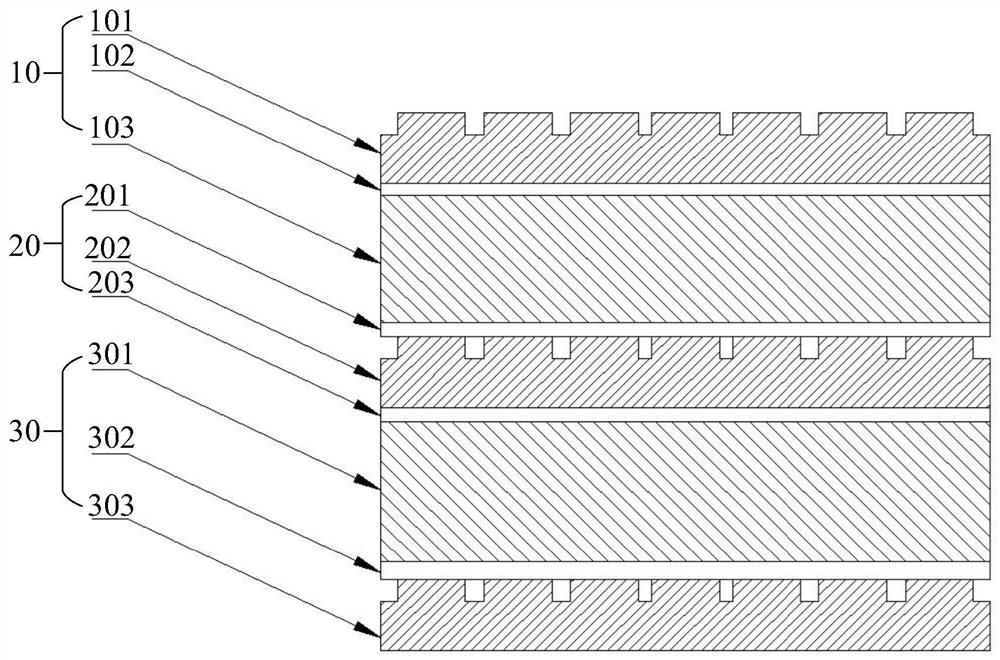

[0049] See figure 1 , figure 1 It is a structural schematic diagram of a selective wave-absorbing surface structure provided by an embodiment of the present invention. An embodiment of the present invention provides a selective wave-absorbing surface structure, the selective wave-absorbing surface structure may include: a frequency selective structure 10, at least one reflective structure 20 and a reinforcement structure 30, wherein the frequency selective structure 10 is located on the reflective structure 20 Above, the reflection structure 20 is located on the enhancement structure 30. In addition, when the number of reflection structures 20 is two or more, multiple reflection structures 20 are arranged on the frequency selective structure 10 and the enhancement structure 30 in a stacked manner. Between, the frequency selective structure 10 can transmit the electromagnetic wave of the working frequency, and can also reflect the electromagnetic wave of the first non-working ...

Embodiment 2

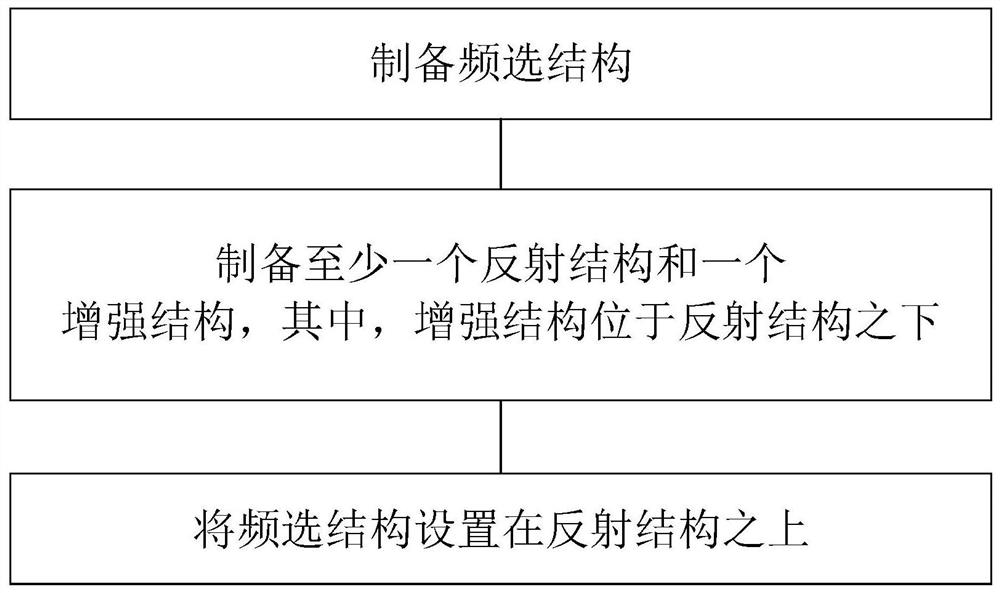

[0089] See image 3 , image 3 It is a schematic flowchart of a method for preparing a selective wave-absorbing surface structure provided by an embodiment of the present invention. This embodiment provides a method for preparing a selective wave-absorbing surface structure on the basis of the above-mentioned embodiments, the preparation method comprising:

[0090] Step 1, see Figure 4a , to prepare the frequency-selective structure 10.

[0091] Step 1.1: Plating a first intermediate layer 102 on the first dielectric layer 103 by using a coating process.

[0092]Preferably, the material of the first intermediate layer 102 is a connection material with high transmittance, which may be a polymer material, such as polyimide.

[0093] Preferably, the thickness of the first intermediate layer 102 ranges from 0 to 0.1 mm.

[0094] Preferably, the material of the first dielectric layer 103 is a non-metallic dielectric material with a dielectric constant of 0-20, such as ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com