Organic component sintering device for perc solar cell

A technology of solar cells and sintering devices, which is applied to circuits, furnace components, electrical components, etc., can solve the problems of sintering devices that are difficult to meet, the height of flamethrower nozzles is fixed, etc., and achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further described below with reference to the accompanying drawings and embodiments.

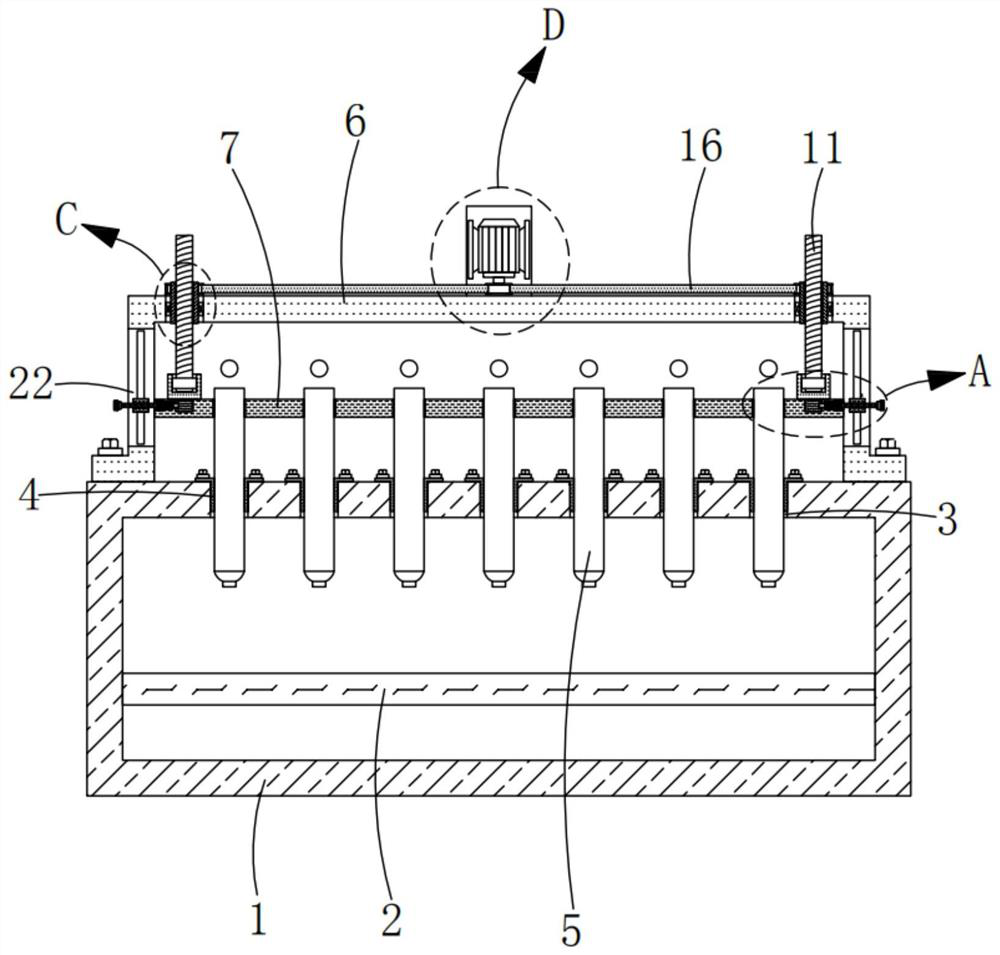

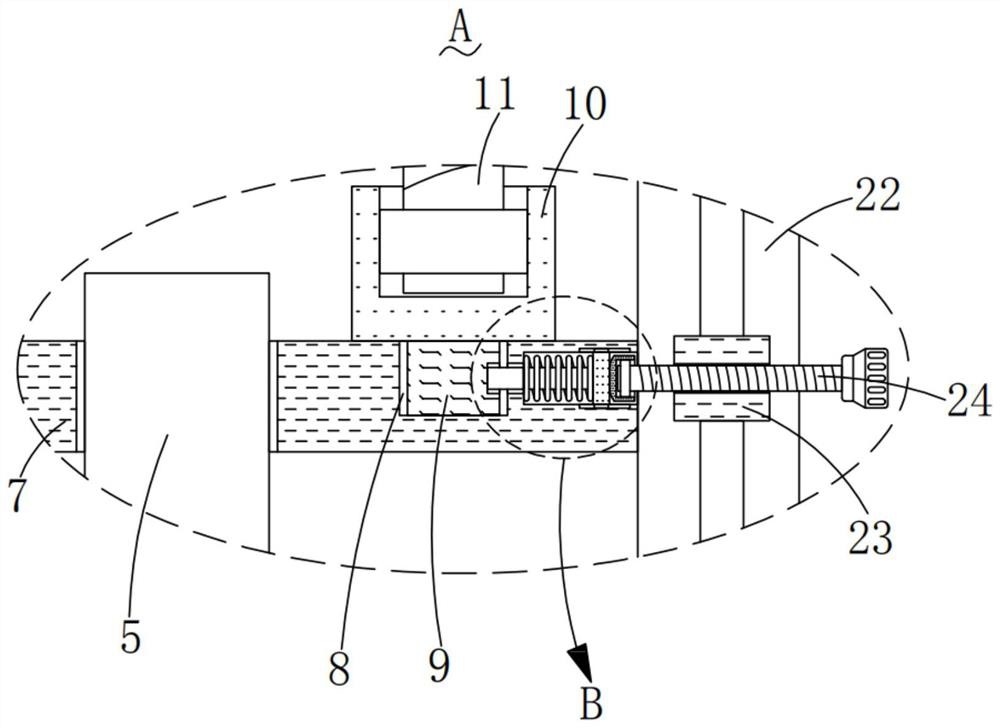

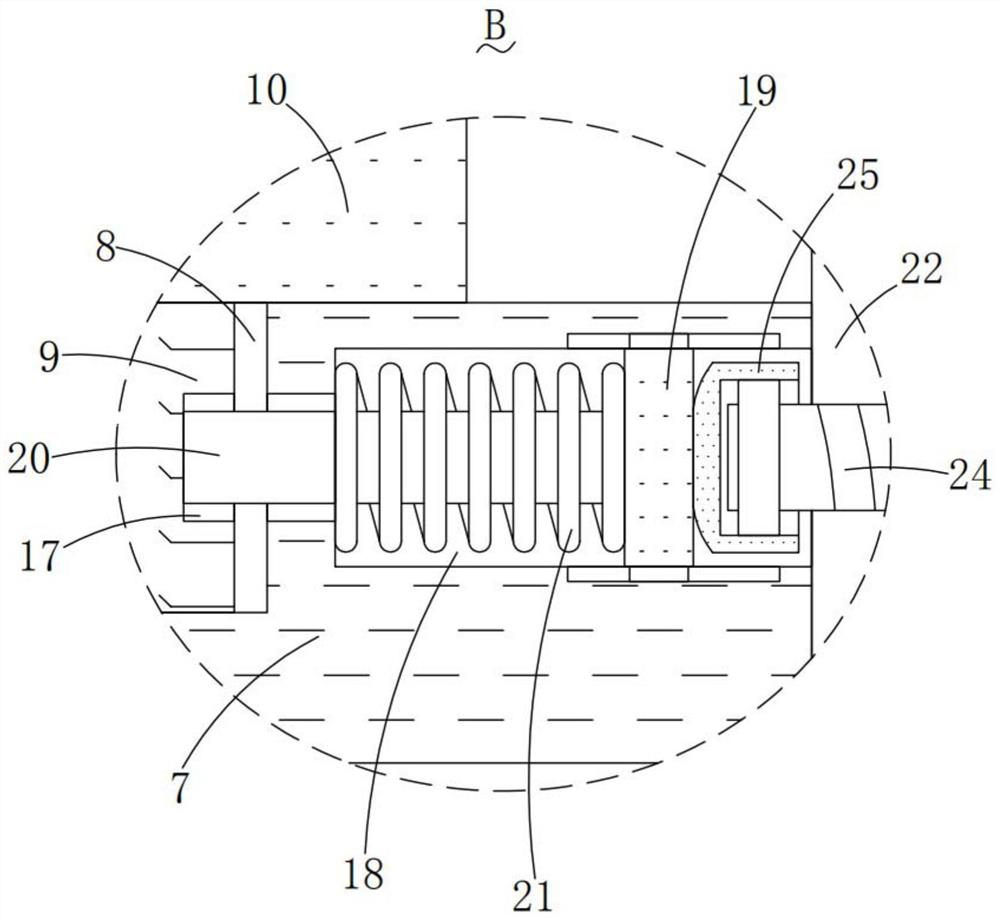

[0029]Please refer tofigure 1 ,figure 2 ,image 3 ,Figure 4 ,Figure 5 ,Figure 6 withFigure 7,among them,figure 1 A structural diagram of a preferred embodiment of the organic component sintering apparatus provided by the present invention;figure 2 forfigure 1 A schematic diagram of the magnification structure shown in Part A shown inimage 3 forfigure 2 A schematic diagram of the magnification structure shown in Part B shown inFigure 4 forfigure 1 A schematic diagram of an enlarged structure of the C portion shown inFigure 5 forfigure 1 A schematic diagram of the magnification structure shown in the D part shown inFigure 6 Schematic view of a top surface structure provided by the connecting plate and nozzle provided by the present invention;Figure 7A side view structure of the protective case, the driven block, and the second screw in the present invention. The PERC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com