Preparation method of thermoplastic polyurethane film

A polyurethane film, thermoplastic technology, applied in the field of preparation of thermoplastic polyurethane film, can solve the problems of poor impact resistance, short service life, large friction coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

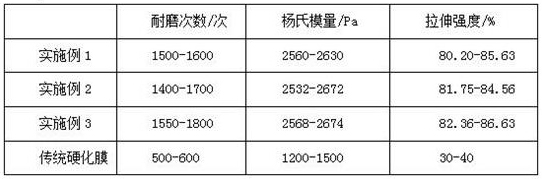

Embodiment 1

[0023] A preparation method of a thermoplastic polyurethane film, comprising the following raw materials in parts by weight: 230 parts of polyurethane, 90 parts of dimethylformamide, 15 parts of antioxidant, 13 parts of ultraviolet absorber, 18 parts of antibacterial Agent, 8 parts of lubricants and 25 parts of fillers, its preparation method specifically comprises the steps:

[0024] S1: Weigh each raw material by weight;

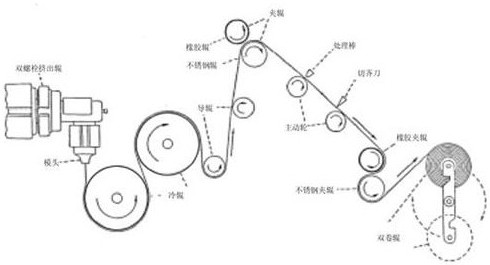

[0025] S2: Put all the raw material components weighed in step S1 into a high-speed kneader for blending and kneading, then take them out and put them into a twin-screw extruder for melt extrusion onto the die, and pass through the die Lay on two or more highly polished chill rolls for cooling;

[0026] S3: Transfer to the nip roller through the double guide rollers for flattening, and then convey to the two driving rollers for compaction and trimming, and then clamp by the double nip rollers, which is most suitable for forming thermoplastics through the ...

Embodiment 2

[0031] A preparation method of a thermoplastic polyurethane film, comprising the following raw materials in parts by weight: 200 parts of polyurethane, 80 parts of dimethylformamide, 10 parts of antioxidant, 10 parts of ultraviolet absorber, 15 parts of antibacterial Agent, 5 parts of lubricants and 20 parts of fillers, its preparation method specifically comprises the steps:

[0032] S1: Weigh each raw material by weight;

[0033] S2: Put all the raw material components weighed in step S1 into a high-speed kneader for blending and kneading, then take them out and put them into a twin-screw extruder for melt extrusion onto the die, and pass through the die Lay on two or more highly polished chill rolls for cooling;

[0034] S3: Transfer to the nip roller through the double guide rollers for flattening, and then convey to the two driving rollers for compaction and trimming, and then clamp by the double nip rollers, which is most suitable for forming thermoplastics through the ...

Embodiment 3

[0039] A preparation method of a thermoplastic polyurethane film, comprising the following raw materials in parts by weight: 250 parts of polyurethane, 100 parts of dimethylformamide, 15 parts of antioxidant, 15 parts of ultraviolet absorber, 20 parts of antibacterial Agent, 10 parts of lubricant and 30 parts of filler, its preparation method specifically comprises the steps:

[0040] S1: Weigh each raw material by weight;

[0041] S2: Put all the raw material components weighed in step S1 into a high-speed kneader for blending and kneading, then take them out and put them into a twin-screw extruder for melt extrusion onto the die, and pass through the die Lay on two or more highly polished chill rolls for cooling;

[0042] S3: Transfer to the nip roller through the double guide rollers for flattening, and then convey to the two driving rollers for compaction and trimming, and then clamp by the double nip rollers, which is most suitable for forming thermoplastics through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com