A multi-material additive manufacturing molding system and method

An additive manufacturing and multi-material technology, applied in the field of additive manufacturing, can solve the problems of large differences in powder properties and printing process compatibility, and achieve the effects of high molding precision, rapid manufacturing, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

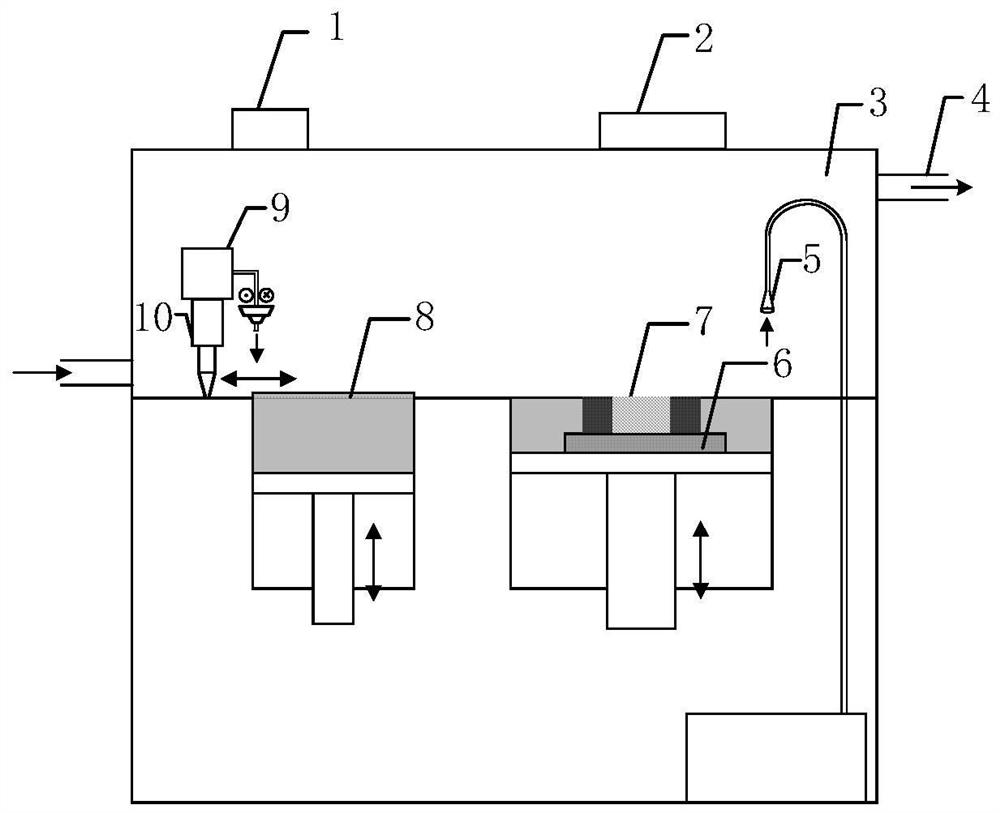

Examples

Embodiment 1

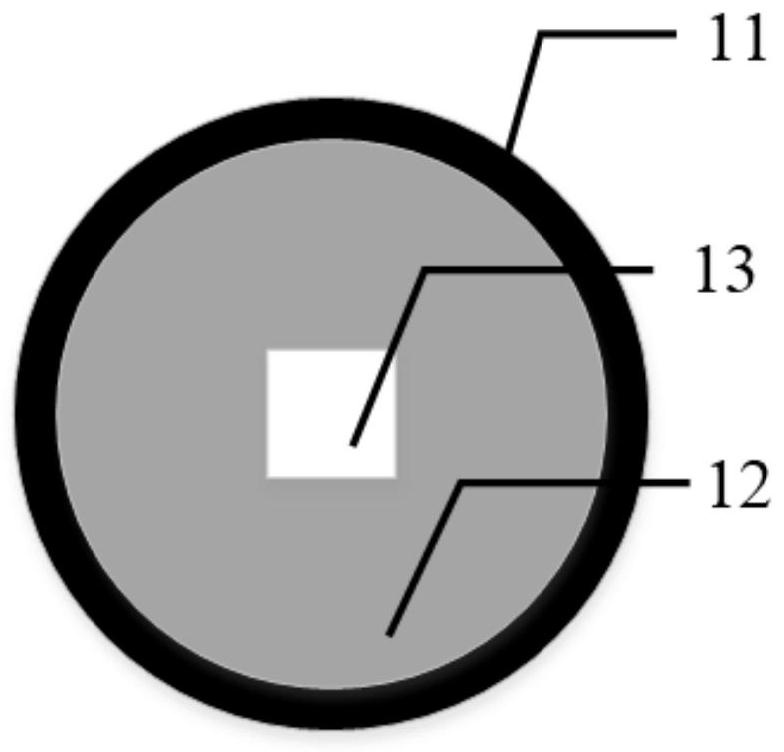

[0070] In the example of the present invention, the parts printed with FeCrAl alloy powder have excellent properties such as uniform structure, high strength, good corrosion resistance, etc. The nickel metal is coated with Al 2 O 3 The ceramics were also shaped with smooth fabrication, with good interfacial contact between the cermet particles.

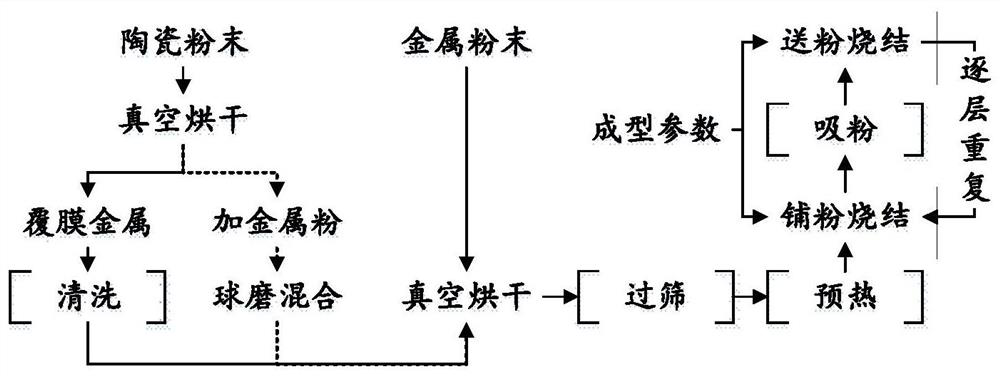

[0071] A multi-material additive manufacturing method according to an embodiment of the present invention includes:

[0072] In step 1, the metal powder is FeCrAl alloy powder, the median particle size is 30 μm, and the ceramic powder is Al 2 O 3 , the median particle size is 20 μm;

[0073] In step 1, during vacuum drying, the drying temperature is set to 100°C, and the vacuum drying is performed for 6 hours;

[0074] In step 1, the mesh number of the sieve is 400 meshes when sieving.

[0075] In step 2, the method of coating the metal is chemical plating, the coating metal is nickel metal, and the coating thickness is 5 μm;

...

Embodiment 2

[0086] A multi-material additive manufacturing method according to an embodiment of the present invention, based on the multi-material additive manufacturing molding system of the present invention, includes the following steps:

[0087] Putting the various raw material powders after vacuum drying and sieving into the plurality of powder storage tanks;

[0088] Set the forming parameters and import the model;

[0089] Introduce protective gas, preheat, and print according to the preset molding process.

[0090] Wherein, when the raw material powder is ceramic powder, the ceramic powder after vacuum drying and sieving is subjected to surface treatment and metallization to obtain the treated ceramic powder; the treated ceramic powder is put into the powder storage tank.

[0091] The thin film method is used for surface treatment and metallization of the ceramic powder after vacuum drying and sieving; wherein, the melting point of the coating metal is lower than that of the cera...

Embodiment 3

[0093] The only difference between the embodiment of the present invention and the embodiment 2 is that the thick film method is used for the surface treatment and metallization of the ceramic powder after vacuum drying and sieving, and the thickness of the coating layer is 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com