An intelligent cooling device for forming aluminum profiles

A technology for cooling devices and aluminum profiles, which is applied in the field of aluminum profile forming cooling devices, can solve problems such as waste of resources, and achieve the effects of saving enterprise costs, improving cooling effects, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

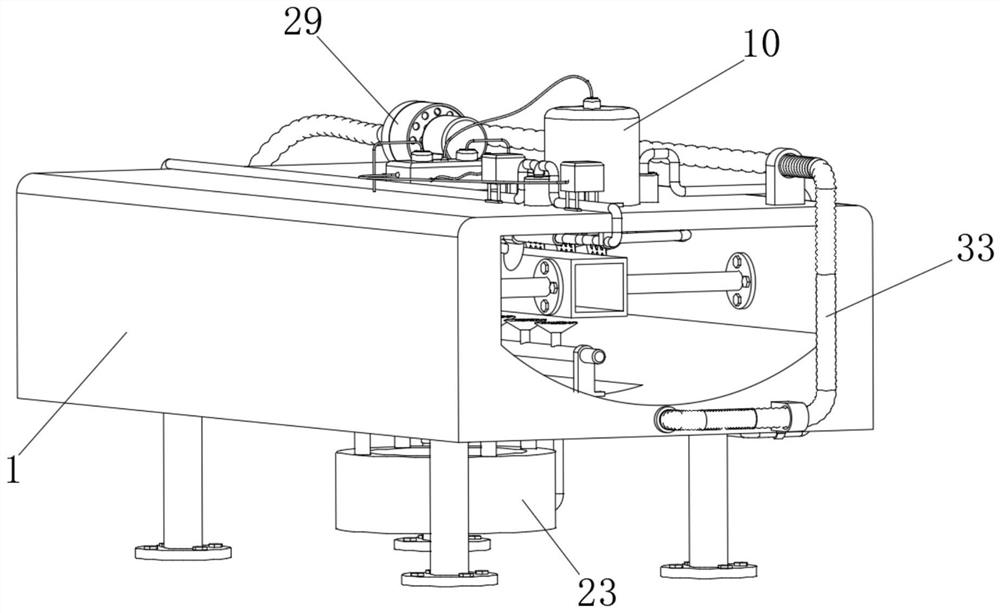

[0034] Embodiment 1: as Figure 1-8 As shown, this embodiment discloses an intelligent cooling device for forming aluminum profiles, including a cooling box 1, two fixed connection plates corresponding to the positions are fixedly connected to the inner walls of the cooling box 1, and four fixed connection plates are fixedly connected to each other. One side of the plate is fixedly connected with a horizontal connecting rod 2, one side of the four horizontal connecting rods 2 is fixedly connected with a fixed plate 3, and the sides of the two fixed plates 3 on the same side are fixedly connected with the same casting The shaping tube 4, the top and the bottom of the casting shaping tube 4 are fixedly connected with a temperature sensor 5, the top of the cooling box 1 is fixedly connected with a controller 6, and the controller 6 is fixedly connected with two temperature wires 7, two temperature wires 7 The other end of the cooling box 1 is fixedly connected to two temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com