Metal bismuth nanoparticle modified porous carbon nitride composite material and preparation method thereof, and application of metal bismuth nanoparticle modified porous carbon nitride composite material in removing antibiotics in water

A composite material, bismuth nanotechnology, applied in chemical instruments and methods, water treatment of special compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the serious recombination of photogenerated electrons and holes and limit photocatalytic performance , unfavorable practical application and other problems, to achieve the effect of narrow particle size distribution, obvious removal effect, good stability and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

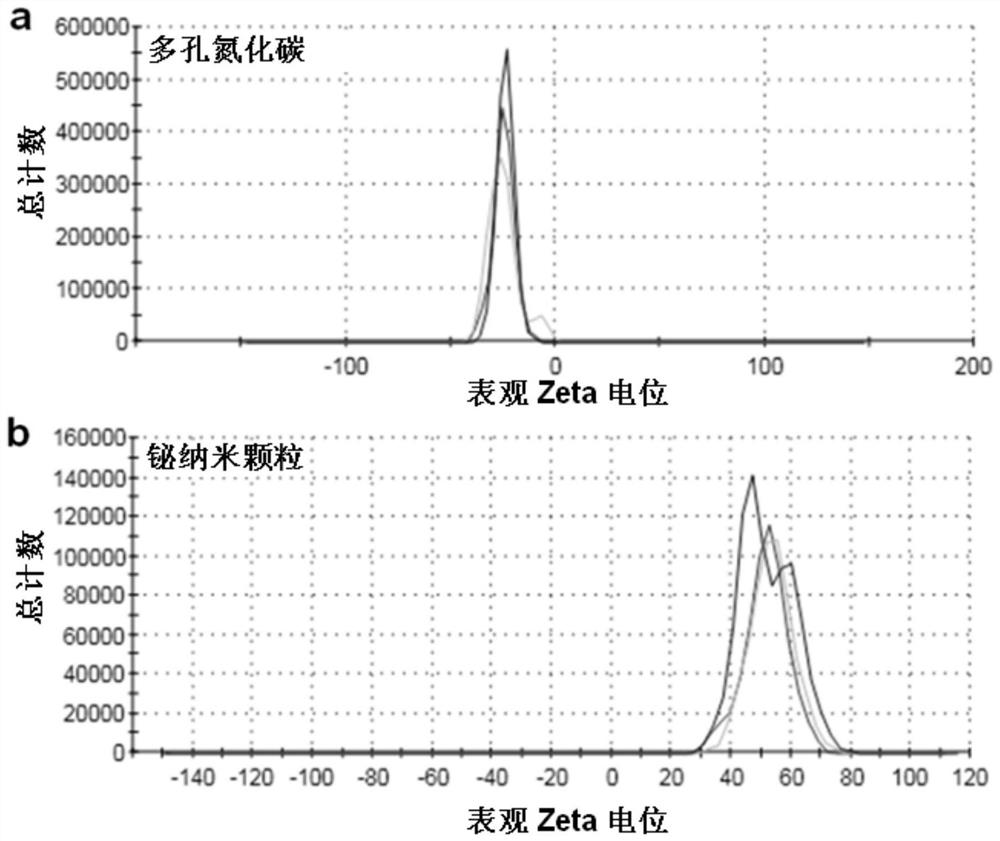

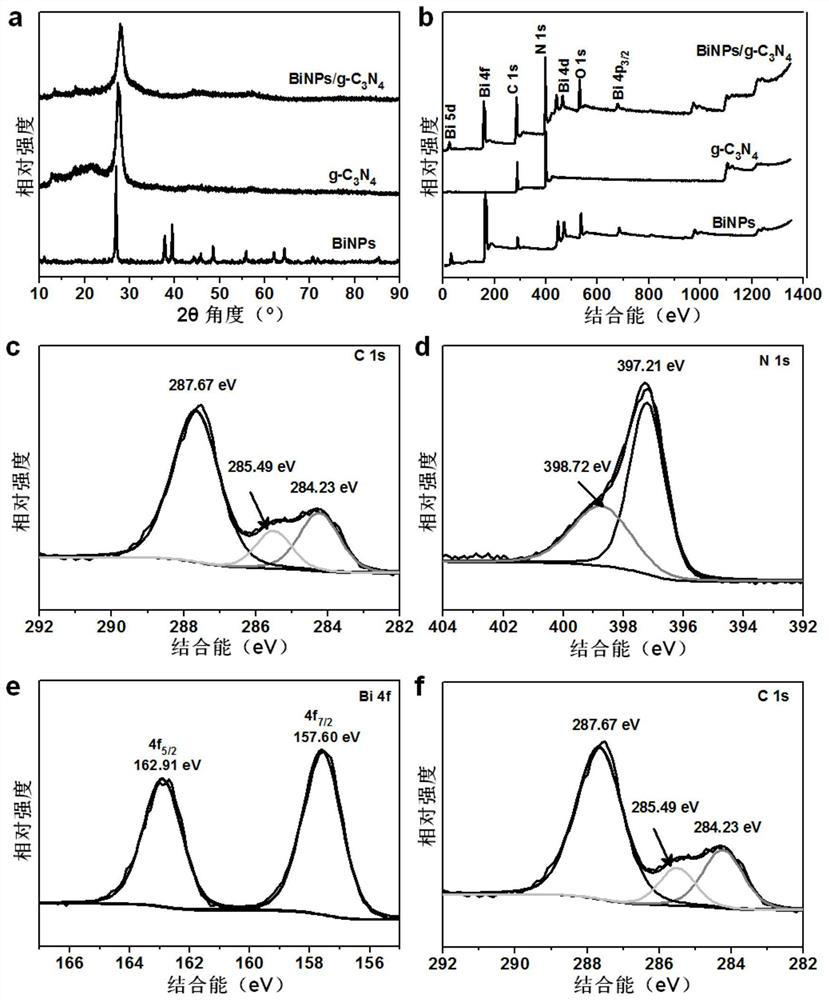

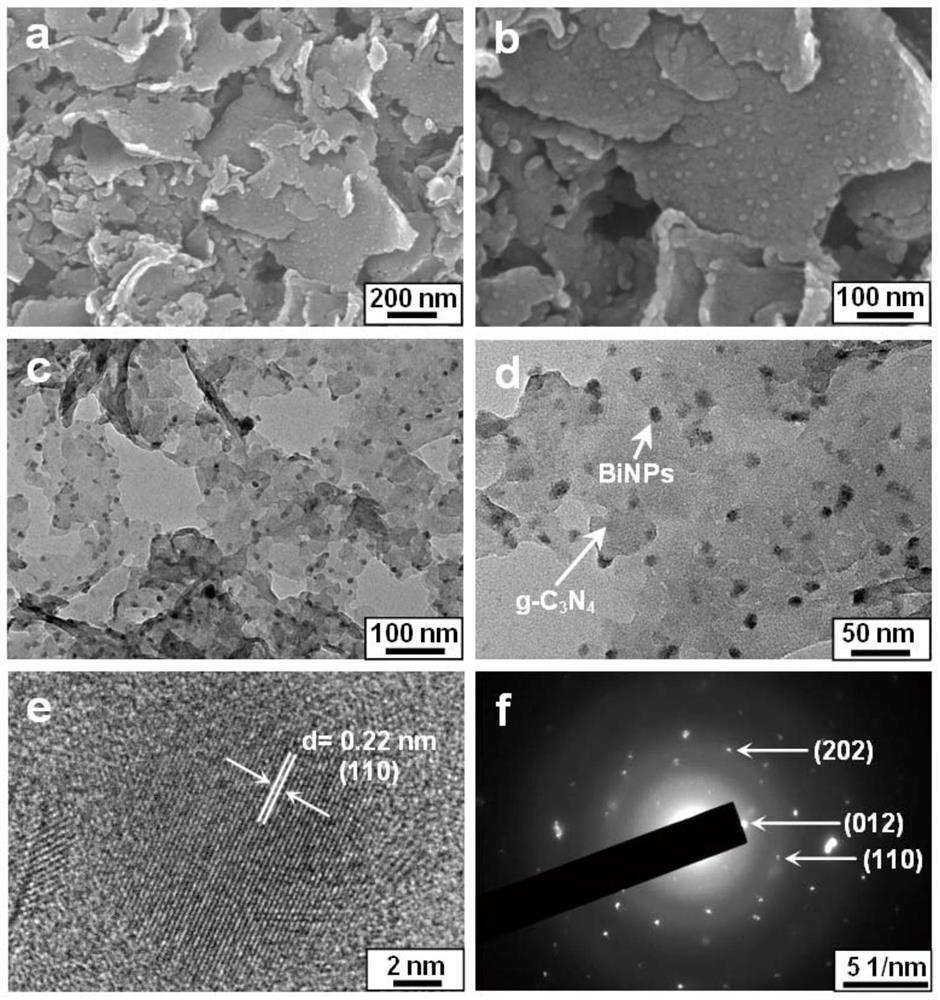

[0069] Dissolve 0.21mmol of bismuth nitrate pentahydrate, 2.1mmol of glucose and 0.62mmol of morpholine borane in 1mL, 2mL and 2mL of 1,2-propanediol, respectively, and transfer the above three solutions to a 50mL double-necked circular tube under the protection of argon. In the bottom flask, continue to pass the gas, seal the bottle mouth, stir and mix evenly, put the round bottom flask into a 260W ultrasonic machine, and ultrasonicate at 25°C for 10min, the color of the mixed solution gradually changes from white to gray black, pour the mixed solution The reaction was terminated by adding 10 mL of pure water, dialyzed in a 3500 MWCO dialysis bag for 2 days, and vacuum / freeze-dried to obtain metallic bismuth nanoparticles (referred to as BiNPs).

[0070] Porous carbon nitride was prepared by pyrolysis and liquid phase exfoliation. The specific process was as follows: put 10g of urea into a 50mL crucible, cover it, and raise the temperature to 550°C at a heating rate of 2.3°C / m...

Embodiment 2

[0075] Metal bismuth nanoparticles and porous carbon nitride were prepared according to the method in Example 1. The difference from Example 1 was that the metal bismuth nanoparticles and porous carbon nitride were ultrasonically dispersed in water at a mass ratio of 1:11.5, and the ultrasonic power was 260W. Ultrasound for 10 minutes, centrifugation, and vacuum / freeze drying to obtain a porous carbon nitride composite material modified with metal bismuth nanoparticles. The mass content of metal bismuth in the composite material is 8%.

[0076] Figure 4 For the characterization of the structure and morphology of the composite material, the structure and morphology of the composite material is consistent with the material in Example 1, the difference is that the content of bismuth nanoparticles is less, indicating that by controlling the quality of metal bismuth nanoparticles and porous carbon nitride Ratio, the content of metal bismuth nanoparticles can be well controlled.

Embodiment 3

[0078] Metal bismuth nanoparticles and porous carbon nitride were prepared according to the method of Example 1. The difference from Example 1 was that the metal bismuth nanoparticles and porous carbon nitride were ultrasonically dispersed in water at a mass ratio of 1:24, and the ultrasonic power was 260W. Ultrasound for 10 minutes, centrifugation, and vacuum / freeze drying to obtain a porous carbon nitride composite material modified with metal bismuth nanoparticles. The mass content of metal bismuth in the composite material is 4%.

[0079] Figure 5 For the characterization of the structure and morphology of the composite material, the structure and morphology of the composite material is consistent with the material in Example 1, except that the distribution density of bismuth nanoparticles on the porous carbon nitride is small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com