Green lotus bean curd and preparation method thereof

A technology of tofu and green lotus, applied in the field of food processing, can solve the problems of elasticity and taste of tofu discharged from yellow pulp water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

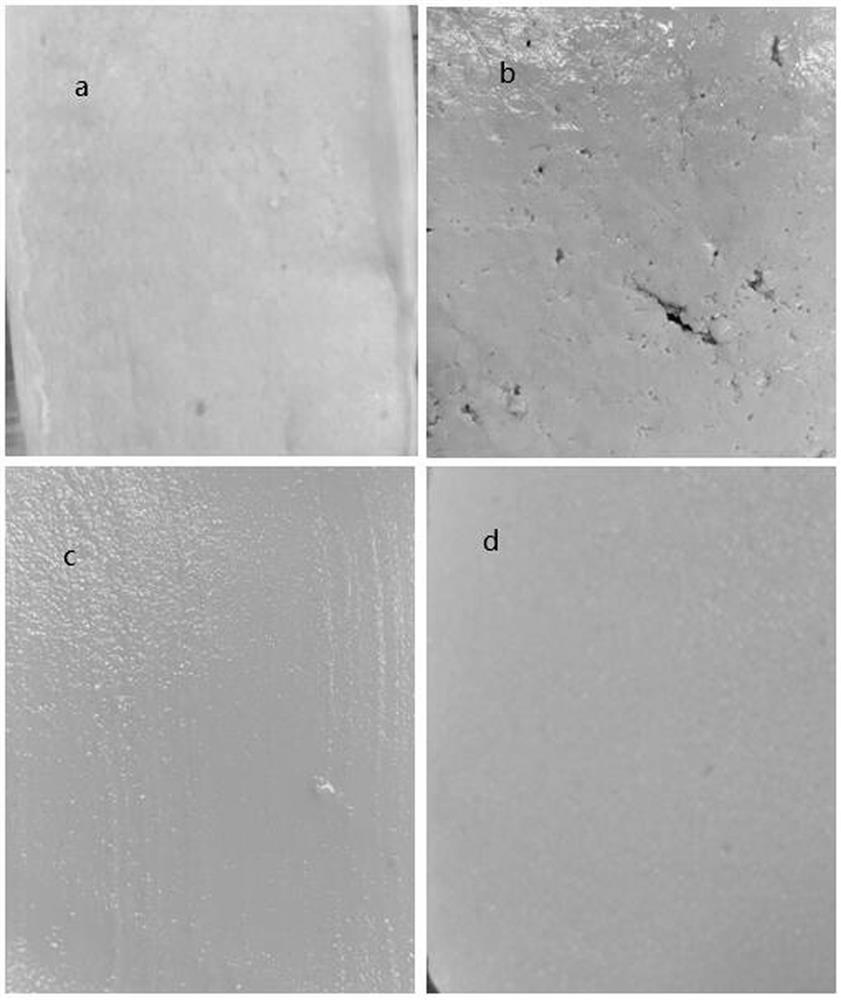

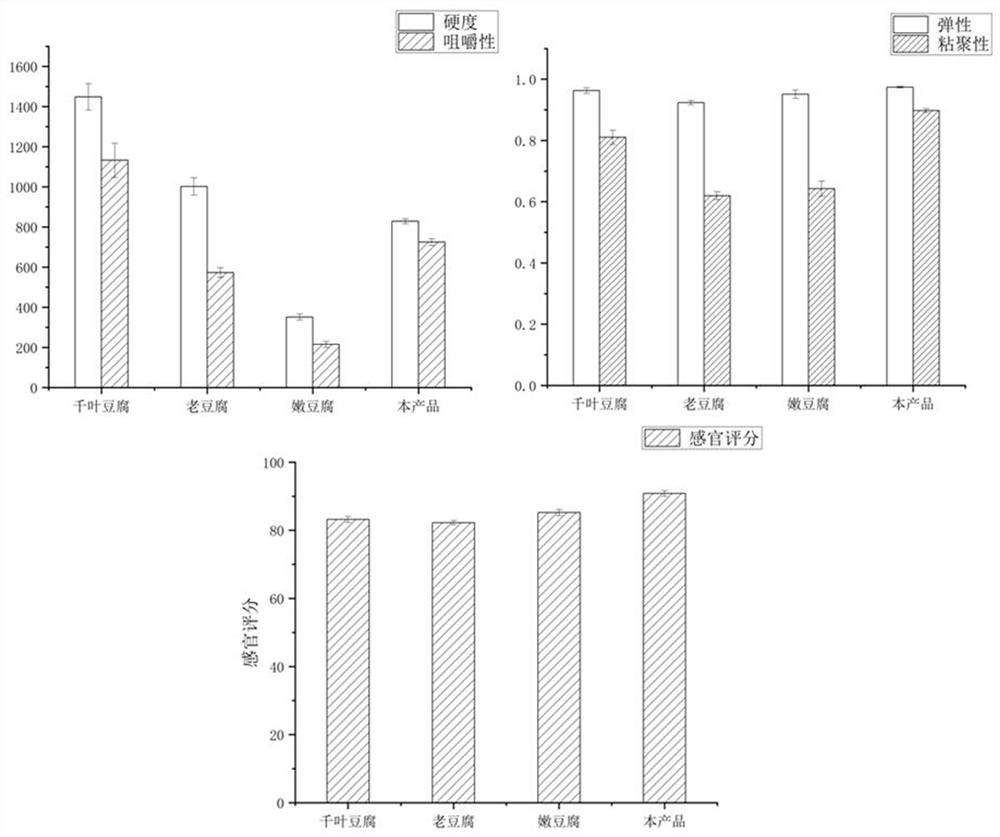

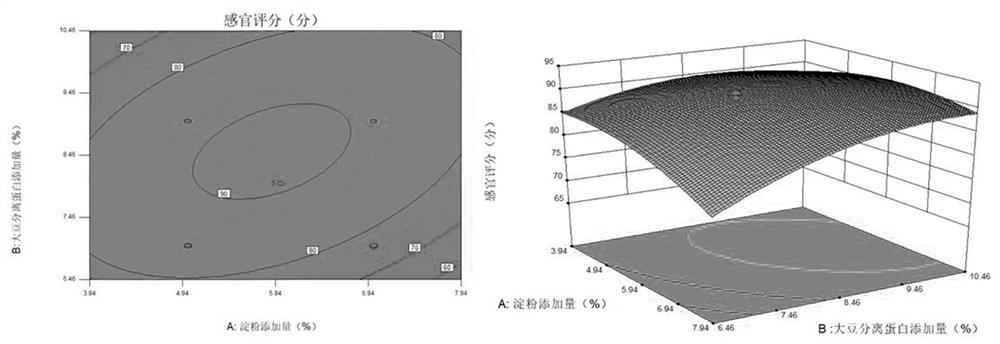

Image

Examples

Embodiment 1

[0027] The preparation method of the green lotus bean curd of the present embodiment, comprises the following steps:

[0028] (1) Soymilk production: Remove impurities from the soybeans, wash them twice with water, soak the beans according to the ratio of soybeans to water 1:4, soak for 12 hours at 20°C, add water until the ratio of soybeans to water is 1:8, filter with four layers of gauze, and boil for 5 minutes .

[0029] (2) Emulsification treatment: the soymilk prepared in step (1) is used as the fixed addition amount, and the addition amount of other raw materials is based on the soymilk addition amount. Accurately weigh 100g of soybean milk prepared in step (1) into the chopping machine, add 8g of soybean protein isolate, chop and mix, add 5g of soybean oil, chop and mix at high speed, then add 0.5g of TG enzyme, beat evenly, and finally add starch 6g, chop and mix until the starch material is completely chopped and mixed evenly, without small granules, and finally a f...

Embodiment 2

[0034] The preparation method of the green lotus bean curd of the present embodiment, comprises the following steps:

[0035] (1) Soymilk production: remove impurities from the soybeans, wash them twice with water, soak the beans according to the ratio of soybeans to water 1:4, soak for 12 hours at 20°C, add water until the ratio of soybeans to water is 1:6, filter through four layers of gauze, and boil for 5 min.

[0036] (2) Emulsification treatment: the soymilk prepared in step (1) is used as the fixed addition amount, and the addition amount of other raw materials is based on the soymilk addition amount. Accurately weigh 100g of soybean milk prepared in step (1) into a chopping machine, add 7g of soybean protein isolate, chop and mix, add 6g of soybean oil, chop and mix at high speed, then add 0.4g of TG enzyme, beat evenly, and finally add starch 8g, chop and mix until the starch material is completely chopped and mixed evenly, without small granules, and finally a fine ...

Embodiment 3

[0041] The preparation method of the green lotus bean curd of the present embodiment, comprises the following steps:

[0042] (1) Soymilk production: Remove impurities from the soybeans, wash them twice with water, soak the beans according to the ratio of soybeans to water 1:6, soak at 4°C for 18 hours, add water until the ratio of soybeans to water is 1:7, filter with four layers of gauze, and boil for 8 hours. min.

[0043](2) Emulsification treatment: the soymilk prepared in step (1) is used as the fixed addition amount, and the addition amount of other raw materials is based on the soymilk addition amount. Accurately weigh 100g of soybean milk prepared in step (1) into a chopping machine, add 6g of soybean protein isolate, chop and mix, add 11g of soybean oil, chop and mix at high speed, then add 0.1g of TG enzyme, beat evenly, and finally add starch 4g, chop and mix until the starch material is completely chopped and mixed without small particles, and finally a fine and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com