Electrolyte, lithium ion battery and formation method

An electrolyte and lithium salt technology, applied in the field of electrochemistry, can solve the problems of vinyl sulfate aggravation, large battery volume changes, affecting battery performance and safety, etc., to improve efficiency and safety, avoid massive gas production, The effect of suppressing the problem of battery gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

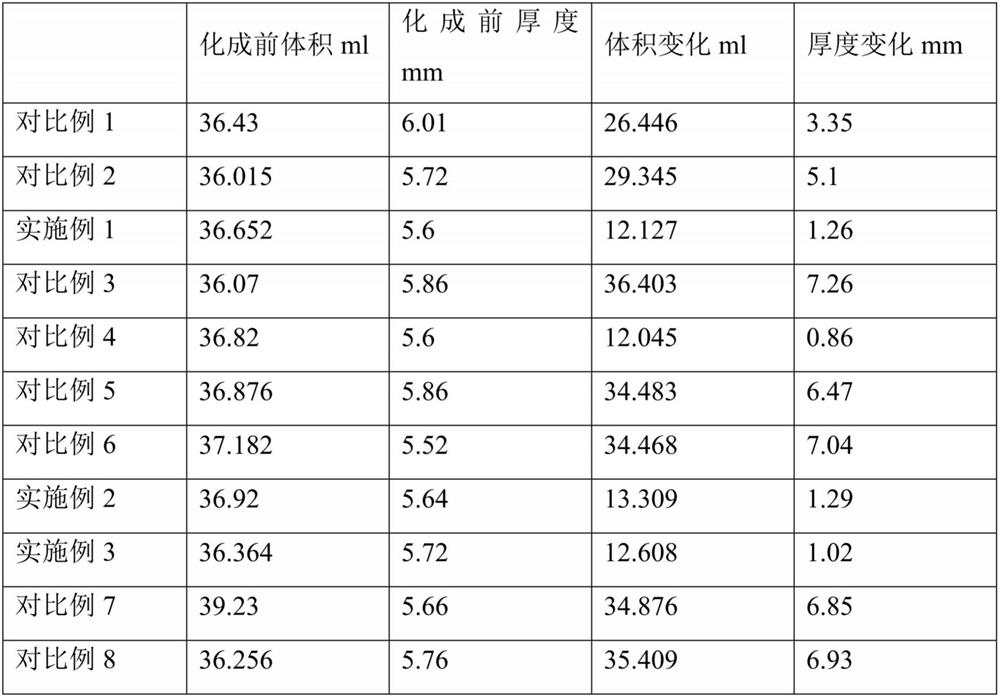

[0025] in an argon-filled glove box (H 2 O6 ) in it, add ethylene sulfate (DTD) of 2% of the total amount of the electrolyte and 1% of the total amount of the electrolyte LiBOB and 1% of the total amount of the electrolyte of vinylene carbonate (VC ). Prepare a lithium-ion battery containing the electrolyte (the positive pole is NCM, the negative pole is graphite), and the battery is formed by charging and discharging at 0.1C. The volume and thickness before and after formation are tested, and the volume is measured by the drainage method. The test results are shown in Table 1.

Embodiment 2

[0035] in an argon-filled glove box (H 2O6 ) in it, add ethylene sulfate (DTD) of 2% of the total amount of the electrolyte and 1% of the total amount of the electrolyte LiDBOB and 1% of the total amount of the electrolyte of vinylene carbonate ( VC). Prepare a lithium-ion battery containing the electrolyte (the positive pole is NCM, the negative pole is graphite), and the battery is formed by charging and discharging at 0.1C. The volume and thickness before and after formation are tested, and the volume is measured by the drainage method. The test results are shown in Table 1.

Embodiment 3

[0037] in an argon-filled glove box (H 2 O6 ) in it, add ethylene sulfate (DTD) of 2% of the total amount of the electrolyte and 1% of the total amount of the electrolyte LiBOB of 1% of the total amount of the electrolyte and 1-3 propane sulfone of the total amount of the electrolyte ester. Prepare a lithium-ion battery containing the electrolyte (the positive pole is NCM, the negative pole is graphite), and the battery is formed by charging and discharging at 0.1C. The volume and thickness before and after formation are tested, and the volume is measured by the drainage method. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com