Propellant supply system and method for attitude control engine vacuum thermal environment test

An environmental test and supply system technology, applied in machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of easy condensation and thermal decomposition, unstable propellant performance, etc., to achieve local low temperature protection, prevent Heat transfer, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

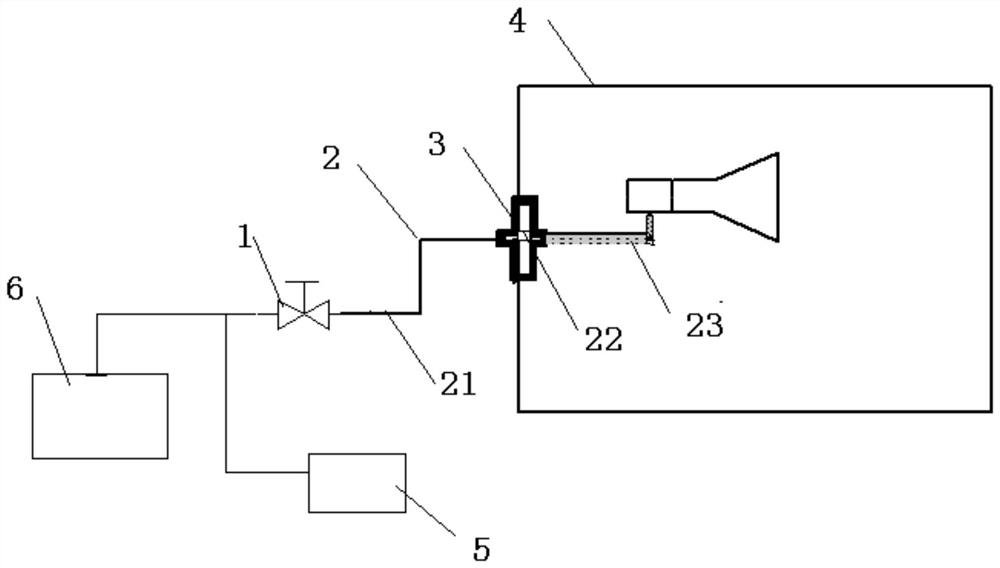

[0043] Such as Figure 1 to Figure 4 As shown, the propellant supply system for the vacuum thermal environment test of the attitude control engine in this embodiment includes a supply pipeline 2, an inlet valve 1 arranged on the supply pipeline 2, and a penetration flange 3. The penetration method The flange 3 is arranged on the vacuum bulkhead 4, and the supply pipeline 2 passes through the penetration flange 3,

[0044] It also includes a vacuum pumping system 5 and a filling and discharging system 6;

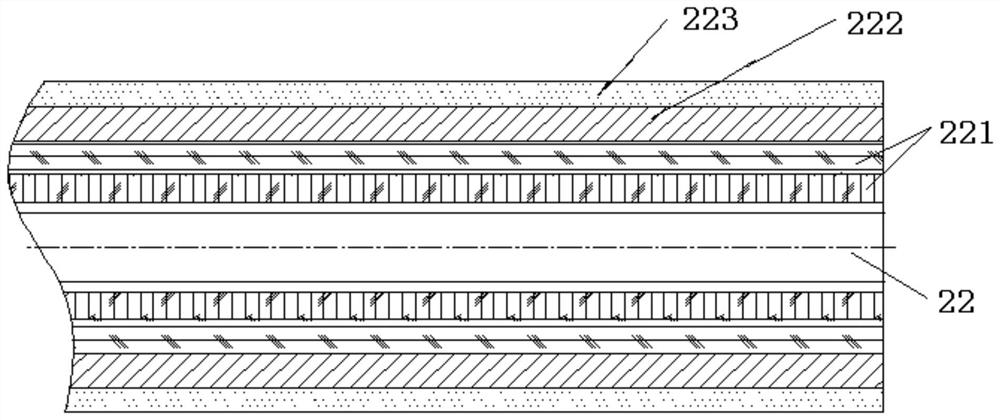

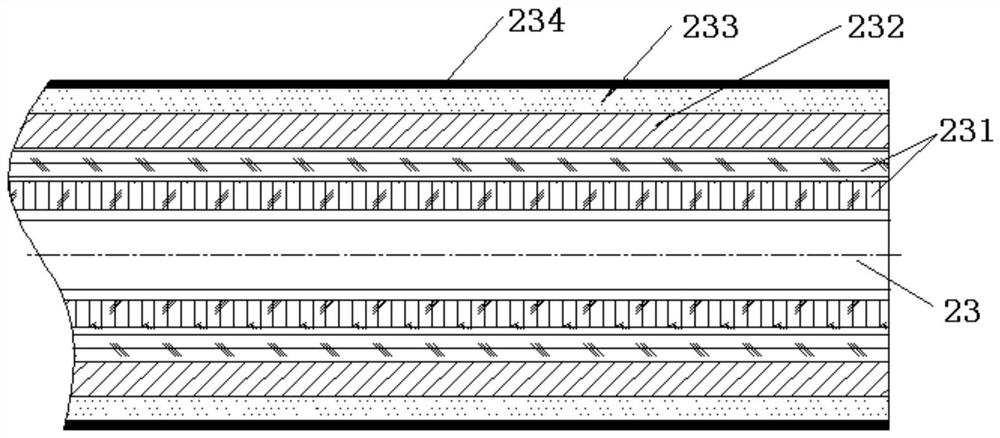

[0045]The supply pipeline 2 includes an outboard pipeline 21, a cabin penetration pipeline 22, and an engine inlet pipeline 23 that are connected in sequence, and the outboard pipeline 21 communicates with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com