Method for preparing topramezone intermediate by utilizing supergravity reaction

A hypergravity reactor, the technology of oxaflutole, which is applied in chemical instruments and methods, preparation of organic compounds, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem of low yield in two steps and post-processing Complex, cumbersome work sections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (control test)

[0036] Add 2,3-dimethyl sulfide (10 g, 0.065 mol) and 50 ml of 1,2-dichloroethane into a 250 mL three-necked flask and dissolve with regular stirring, and cool down to 5°C. After cooling down, 48% hydrobromic acid aqueous solution (14.4 g, 0.08 mol) and hydrogen peroxide (22.34 g, 0.197 mol) were added dropwise thereto at the same time, and the temperature was controlled and added dropwise at 5°C. After the dropwise addition, keep warm for 10 minutes, then raise the temperature to 15°C and keep warm for 2 hours. Liquid phase detection reaction. The peak area ratio of 2,3-dimethyl-4-methylsulfonylbromobenzene product is 35.7%, and the peak area ratio of single oxide impurity is 55.1%. Raw materials were not detected.

[0037] This experiment proves that it is difficult to achieve one-pot bromination oxidation of 2,3-dimethyl sulfide under conventional stirring equipment.

[0038] The following is an implementation case of using hypergrav...

Embodiment 2

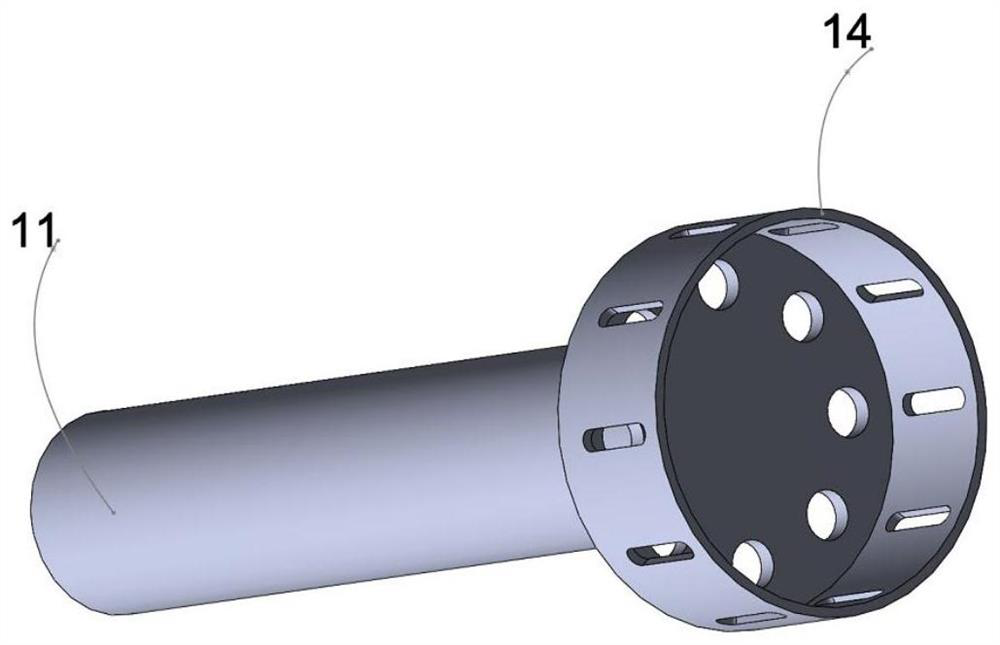

[0040] Turn on the hypergravity response of the silica material, O 3The gas is metered by the rotameter, and the first gas inlet 1 of the supergravity reaction shell is used to fill the layer along the tangential direction. From the ethylene dichloride solution (50g 2,3-dimethyl sulfide+250ml ethylene dichloride) of the 2,3-dimethyl sulfide of raw material tank 6 after raw material pump 5 metering and from the second gas inlet 3 The hydrobromic acid gas measured by the rotameter enters from the supergravity reaction center together, and the gas-liquid two-phase is mixed at high speed to control the 2,3-dimethyl sulfide, O 3 The molar ratio of feed flow rate and hydrobromic acid gas is 1:6:1.3, the reaction temperature is set at 40°C, and the reaction pressure is 1MP. The rotor speed is 800r / min. The gas after the reaction (containing O 2 ) is drawn through the gas outlet 2, and the liquid after the reaction is thrown out of the packing layer, collected by the shell of the s...

Embodiment 3

[0042] Turn on the hypergravity response of the silica material, O 3 The gas is metered by the rotameter, and the first gas inlet 1 of the supergravity reaction shell is used to fill the layer along the tangential direction. From the ethylene dichloride solution (50g2,3-dimethyl sulfide+250ml ethylene dichloride) of the 2,3-dimethyl sulfide of raw material tank 6 after raw material pump 5 metering and from the second gas inlet 3 The hydrobromic acid gas measured by the rotameter enters from the supergravity reaction center together, and the gas-liquid two-phase is mixed at high speed to control the 2,3-dimethyl sulfide, O 3 The molar ratio of feed flow rate to hydrobromic acid gas is 1:5:1.3, the reaction temperature is set at 40°C, and the reaction pressure is 1MP. The rotor speed is 800r / min. The gas after the reaction (containing O 2 ) is drawn through the gas outlet 2, and the liquid after the reaction is thrown out of the packing layer, collected by the shell of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com