Improved silicon carbide raw material synthesis method

A synthesis method and technology of silicon carbide, applied in the direction of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of reducing the average particle size and unsatisfactory raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

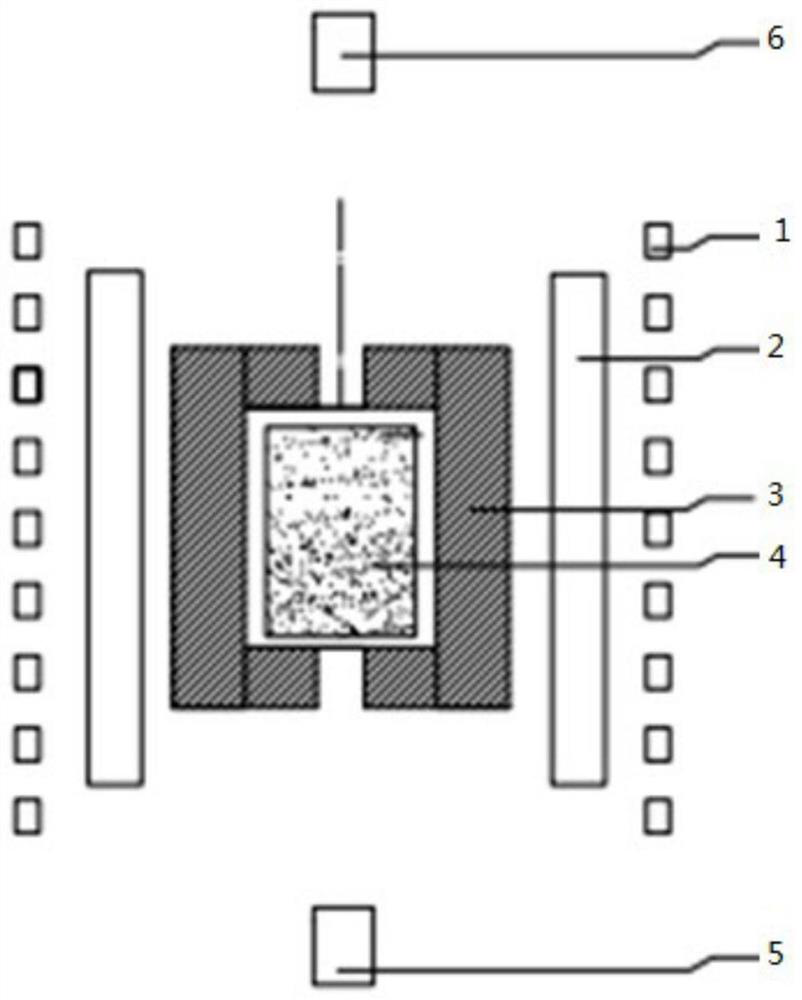

[0019] A silicon carbide raw material synthesis system, characterized in that it includes a coil 1, a quartz tube 2, an insulation cylinder 3, a raw material powder 4, a lower thermometer 5, an upper thermometer 6, and a graphite crucible 7. And synthesis furnace, mechanical pump, molecular pump, motor screw drive device 8.

[0020] Preferably, the insulation cylinder 3, the raw material powder 4, the lower thermometer 5, the upper thermometer 6, and the graphite crucible 7 are all located in the synthesis furnace.

[0021] The quartz tube 2 is located between the two sets of coils 1 and the insulation cylinder 3, the graphite crucible is located in the insulation cylinder, the raw material powder is located in the graphite crucible, the lower thermometer 5 is located under the insulation cylinder, and the upper thermometer 6 is located in the insulation cylinder above.

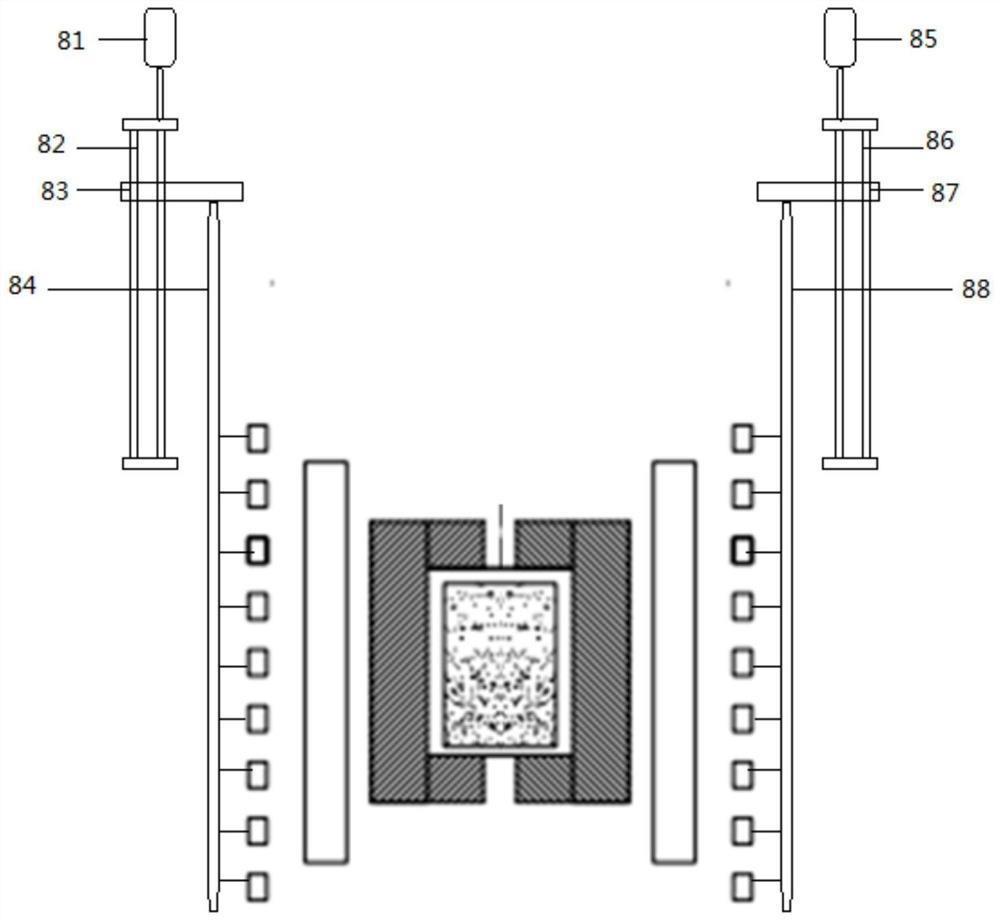

[0022] Described motor screw mandrel transmission device 8 comprises left motor 81, left screw mandrel 82...

Embodiment 2

[0026] A method for synthesizing silicon carbide raw materials: (1) Weigh carbon powder and silicon powder with a molar ratio of 1:1.01-1.10, and add 0.1%-0.5% polytetrafluoroethylene powder of the total weight of carbon powder and silicon powder, Mix and grind in the ball mill tank for more than 1 hour to obtain the mixture of step (1); (1A) carry out the test run step in advance, by recording the data of the starting position of the movement of the left motor and the right motor, the rotation of the motor and the moving distance of the two groups of coils (1) Quantitative relationship, prepare preset mobile program for PLC controller; (2) put step (1) mixture into graphite crucible, and put crucible into silicon carbide raw material synthesis furnace; (3) use mechanical pump and molecular pump to The pressure in the synthesis furnace is pumped down to below 10-2Pa, and heating is started. During the heating process, when the heating reaches 1400-1600°C, the position of the co...

Embodiment 3

[0028] A method for synthesizing a silicon carbide crystal raw material, the method comprising the following steps: first weighing a certain amount of carbon powder and silicon powder, putting them into a ball milling jar, then weighing an appropriate amount of polytetrafluoroethylene, adding them into the ball milling jar and mixing evenly ; (2) Put the above mixture into a graphite crucible, put the crucible into a silicon carbide raw material synthesis furnace, adjust the induction coil of the raw material synthesis furnace to a suitable position; (3) use a mechanical pump and a molecular pump to synthesize the silicon carbide raw material The pressure in the furnace is pumped to 10 -2 Below Pa, start heating, and after heating to an appropriate temperature, start to move the position of the induction coil; (4) After the heating is completed, pour a certain proportion of argon and helium into the chamber of the silicon carbide raw material synthesis furnace, and naturally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com