Method for preparing high-performance organic gas separation membrane

An organic gas, separation membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of low surface free energy, easy to fall off, high hydrophobicity, etc., to achieve high temperature resistance performance, cost Inexpensive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of the first mixed solution:

[0049] (1A) mixing N, N-dimethylpyrrolidone, terephthalic acid, and zirconium tetrachloride in a molar ratio of 500:1:1 and fully stirring to obtain the solution required for MOFs membrane preparation;

[0050] (1B) After the polypropylene hollow fiber base membrane with a pore size of 500 nm prepared by melt stretching was washed twice with water, washed with ethanol twice and dried, the ratio of the specific surface area of the base membrane to the volume of the MOFs preparation solution was 50:1 (i.e. the surface For 50 square meters of film put 1m 3 solution), put it into the solution required for MOFs preparation to obtain the first mixed solution.

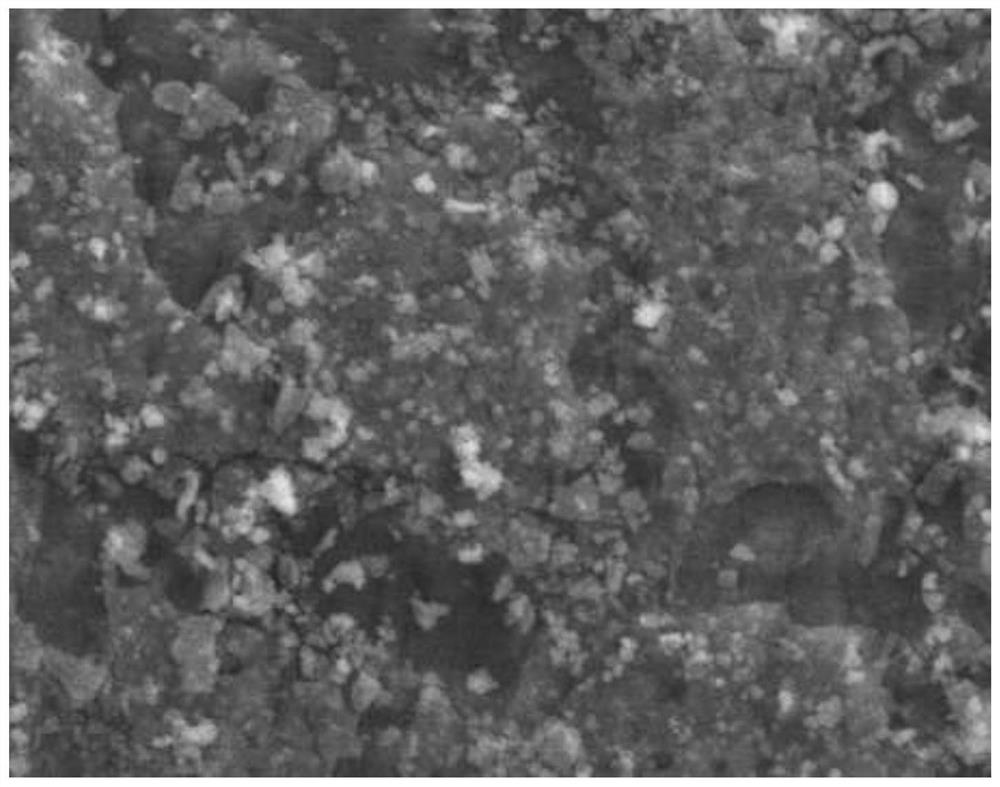

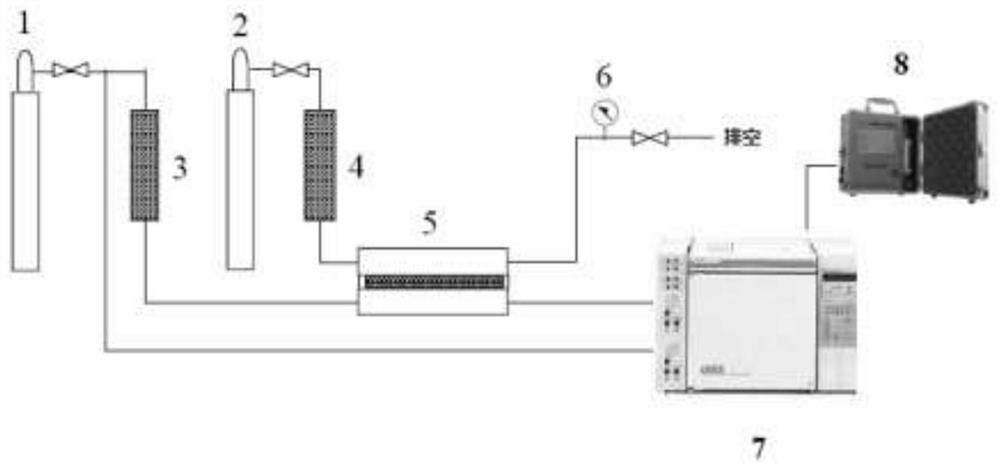

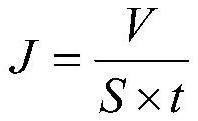

[0051] (2) Preparation of MOFs functional layer: The reactor is sealed, and nitrogen is passed through under dry conditions to protect and exhaust oxygen. Put the first mixed solution prepared in step (1) into a reactor at 150° C., and perform a solvothermal reaction f...

Embodiment 2

[0058] (1) Preparation of the first mixed solution:

[0059] (1A) mixing N, N-dimethylpyrrolidone, terephthalic acid, and zirconium tetrachloride in a molar ratio of 200:1:1 and fully stirring to obtain the solution required for MOFs membrane preparation;

[0060] (1B) After the polypropylene hollow fiber base membrane with a pore size of 200 nm prepared by solution-induced phase separation was washed twice with water, washed with ethanol twice and dried, the ratio of the specific surface area of the base membrane to the volume of the MOFs prepared solution was 10:1 (ie A film with a surface of 10 square meters is placed in 1m 3 solution), put it into the solution required for MOFs preparation to obtain the first mixed solution.

[0061] (2) Preparation of MOFs functional layer: The reactor is sealed, and nitrogen is passed through under dry conditions to protect and exhaust oxygen. Put the first mixed solution prepared in step (1) into a reactor at 150° C., and perform a ...

Embodiment 3

[0067] (1) Preparation of the first mixed solution:

[0068] (1A) mixing N, N-dimethylpyrrolidone, terephthalic acid, and zirconium tetrachloride in a molar ratio of 100:1:1 and fully stirring to obtain the solution required for MOFs membrane preparation;

[0069] (1B) After the 500nm pore diameter polypropylene flat base membrane prepared by thermal phase separation was washed twice with water, washed with ethanol twice and dried, the specific surface area of the base membrane and the volume ratio of the MOFs preparation solution were 1:1 (i.e. A film with a surface of 1 square meter is placed in 1m 3 solution), put it into the MOFs preparation solution to obtain the first mixed solution.

[0070] (2) Preparation of MOFs functional layer: The reactor is sealed, and nitrogen is passed through under dry conditions to protect and exhaust oxygen. Put the first mixed solution prepared in step (1) into a reactor at 200° C., and perform a solvothermal reaction for 2 hours to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com