Diaphragm thermal shrinkage evaluation method

A technology of thermal shrinkage and diaphragm, applied in the direction of thermal expansion coefficient of materials, etc., can solve the problems of thermal safety error, difference in thermal shrinkage of diaphragm, etc., to achieve the effect of simple evaluation method, improved accuracy and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] A method for evaluating diaphragm heat shrinkage, comprising the following steps:

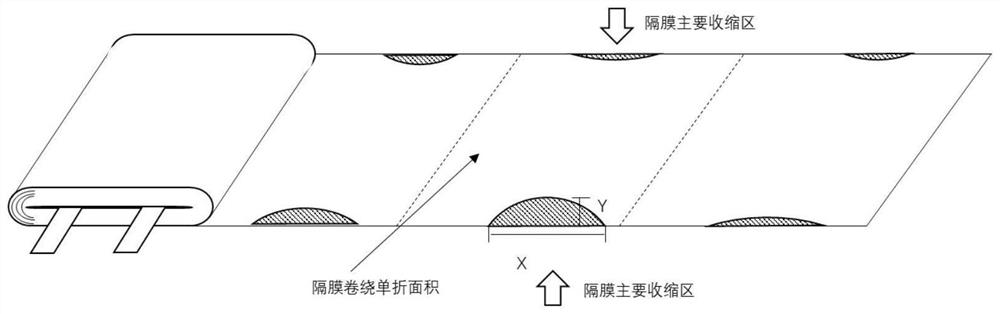

[0044] 1) Take the diaphragm to be tested, such as figure 1As shown, make a cross mark on it, the cross mark is evenly distributed in the length direction and width direction of the diaphragm, the cross mark includes horizontal lines and vertical lines, measure the original length X of the horizontal lines and the vertical lines 1 and Y 1 ;

[0045] 2) Wind the separator to be tested with the cross mark and the positive electrode sheet and the negative electrode sheet into a shape such as figure 2 For the cells shown, the separator is located between the positive and negative plates;

[0046] 3) Place the coiled cells at 130°C for 0.5h, 1h, 2h and 6h, then take them out, disassemble them, and take out the diaphragm for evaluation;

[0047] 4) Measure the length X of the horizontal line and the vertical line after the cross mark on the diaphragm is cooled to room temperature 2 and Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com