Preparation method of starch telluride-based bionic glutathione peroxidase

A technology of glutathione peroxide and starch, applied in the field of modified starch, can solve the problems of high cost and poor performance, and achieve the effects of stable structure and performance and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

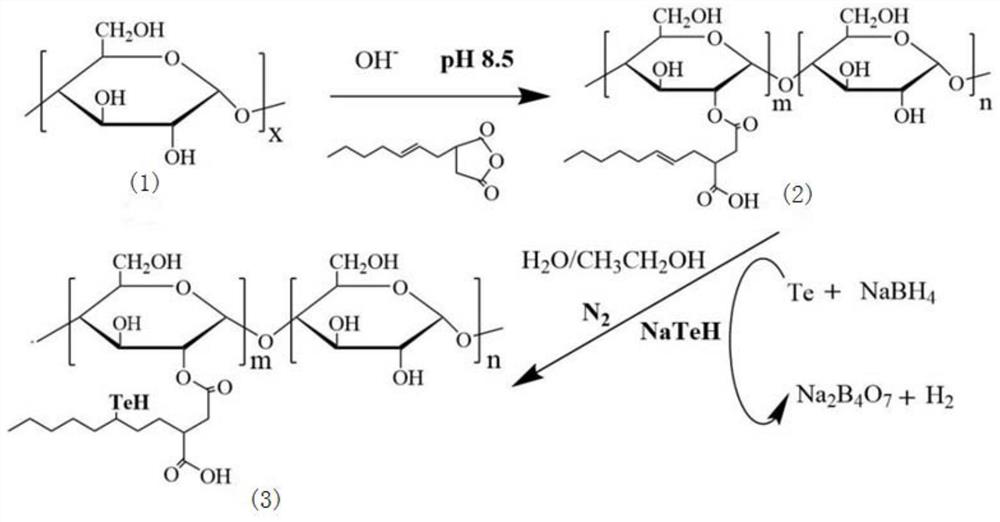

[0032] The preparation method of telluride starch-based biomimetic glutathione peroxidase comprises the following steps:

[0033] 1) Weighing 30g of tapioca starch as a raw material, adding water to form a 30% starch emulsion, taking octenyl succinic anhydride with a dry weight of tapioca starch of 3.5%, and diluting it with 3 times the quality of absolute ethanol;

[0034] 2) Slowly drop octenyl succinic anhydride ethanol solution into the starch emulsion for reaction, use 3% NaOH solution to maintain the pH value of the reaction system to 8.5 during the reaction, and react at 40° C. for 4 hours;

[0035] 3) After the reaction, wash with deionized water and ethanol in sequence, filter, and dry to obtain starch octenyl succinate, that is, the OSA starch sample, and set aside;

[0036] 4) Take 0.1818g tellurium and 0.3636g potassium borohydride to react with 30mL water under nitrogen atmosphere to prepare sodium tellurium hydride solution for later use;

[0037] 5) Get 10g of ...

Embodiment 2

[0040] The preparation method of telluride starch-based biomimetic glutathione peroxidase comprises the following steps:

[0041] 1) Weigh 30g of tapioca starch as raw material, add water, configure 30% starch emulsion, take octenyl succinic anhydride with 3.5% dry weight of tapioca starch, and dilute with 4 times of absolute ethanol to obtain octenyl succinic anhydride Succinic anhydride ethanol solution for subsequent use;

[0042] 2) Slowly drop octenyl succinic anhydride ethanol solution into the starch emulsion for reaction, use 3% NaOH solution to maintain the pH value of the reaction system to 8.1 during the reaction, and react at 37° C. for 3 hours;

[0043] 3) After the reaction, wash with deionized water and ethanol in sequence, filter, and dry to obtain starch octenyl succinate, i.e. OSA starch sample, for subsequent use;

[0044] 4) Take 0.1818g tellurium and 0.7272g potassium borohydride and react with 30mL water under nitrogen atmosphere to prepare sodium tellur...

Embodiment 3

[0048] The preparation method of telluride starch-based biomimetic glutathione peroxidase comprises the following steps:

[0049] 1) Weigh 30g of tapioca starch as raw material, add water, configure 30% starch emulsion, take octenyl succinic anhydride with 3.5% dry weight of tapioca starch, and dilute it with 5 times of absolute ethanol to obtain octene Base succinic anhydride ethanol solution for subsequent use;

[0050] 2) Slowly drop octenyl succinic anhydride ethanol solution into the starch emulsion for reaction, use 3% NaOH solution to maintain the pH value of the reaction system to 8.3 during the reaction, and react at 43°C for 3.5h;

[0051] 3) After the reaction, wash with deionized water and ethanol in sequence, filter, and dry to obtain starch octenyl succinate, that is, the OSA starch sample, and set aside;

[0052]4) Take 0.1818g tellurium and 1.0908g potassium borohydride and react with 30mL water under nitrogen atmosphere to prepare sodium tellurium hydride sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com