Composite steel plate for multi-layer tool and preparation method thereof

A composite steel plate and cutting tool technology, which is applied in the field of iron and steel metallurgy, can solve the problems of stagnation in the development and research of cutting tool raw materials, disproportionate steel consumption, and reluctance to invest too much, so as to increase tempering stability, increase service life, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

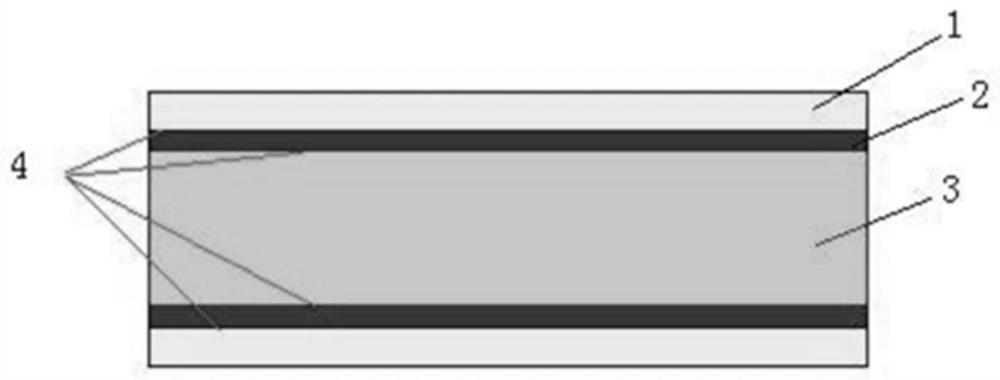

[0036] The present invention provides a method for preparing the above-mentioned composite steel plate for multi-layer cutting tools, comprising the following steps:

[0037] A: Raw material preparation

[0038] Nickel plate and pure titanium plate are produced or purchased according to national standards; the thickness of the base plate is 100-500mm, the thickness of the middle plate is 1-10mm, and the thickness of the outer layer is 10-50mm;

[0039] The base plate, the outer layer plate and the middle plate are processed to the same size, the contact surface of the slab is cleaned of oxide scale and the surface of the slab is degreasing;

[0040] B: Assembly and welding

[0041] Place the middle plate and outer layer plate on the top and bottom of the substrate in turn. After the placement is completed, spot welding the sides of each layer of steel plates; send the spot-welded blanks to a vacuum electron beam welding box to seal and weld the contact surfaces. The degree of...

Embodiment 1

[0061] In this embodiment, the thickness of the base plate is 100mm, the thickness of the middle plate is 1mm, and the thickness of the outer layer plate is 10mm to produce a composite steel plate for multi-layer cutting tools. The steps include:

[0062] A: Raw material preparation

[0063] a. The base plate, the outer titanium plate and the intermediate plate are processed to the same size, and the contact surface of the slab is cleaned of oxide scale for use;

[0064] b. Degrease the surface of the slab after processing;

[0065] B: Assembly and welding

[0066] a. Place the intermediate plate and the titanium plate in sequence on the top and bottom of the substrate;

[0067] b. After the placement is completed, spot welding the sides of each layer of steel plates;

[0068] c. Send the spot-welded blank to a vacuum electron beam welding box to seal and weld the contact surface, and the vacuum degree is 0.008Pa;

[0069] C: heating

[0070] a. Use a trolley-type heating...

Embodiment 2

[0089] In this embodiment, the thickness of the base plate is 500mm, the thickness of the intermediate plate is 10mm, and the thickness of the outer titanium plate is 50mm to produce a composite steel plate for multi-layer cutting tools. The steps include:

[0090] A: Raw material preparation

[0091] a. The base plate, the outer titanium plate and the intermediate plate are processed to the same size, and the contact surface of the slab is cleaned of oxide scale for use;

[0092] b. Degrease the surface of the slab after processing;

[0093] B: Assembly and welding

[0094] a. Place the intermediate plate and the titanium plate in sequence on the top and bottom of the substrate;

[0095] b. After the placement is completed, spot welding the sides of each layer of steel plates;

[0096] c. Send the spot-welded blank to a vacuum electron beam welding box to seal and weld the contact surface, and the vacuum degree is 0.005Pa;

[0097] C: heating

[0098] a. It is heated by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com