Device and method for manufacturing positive electrode active material precursor

A technology for positive electrode active materials and precursors, which is applied in the field of manufacturing positive electrode active material precursors, can solve the problems of residence time and reaction time deviation, reduced productivity, and uneven size and particle size of positive electrode active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Embodiment 1: the manufacture of cathode active material precursor

[0131] 1. Manufacture of equipment for the manufacture of cathode active material precursors

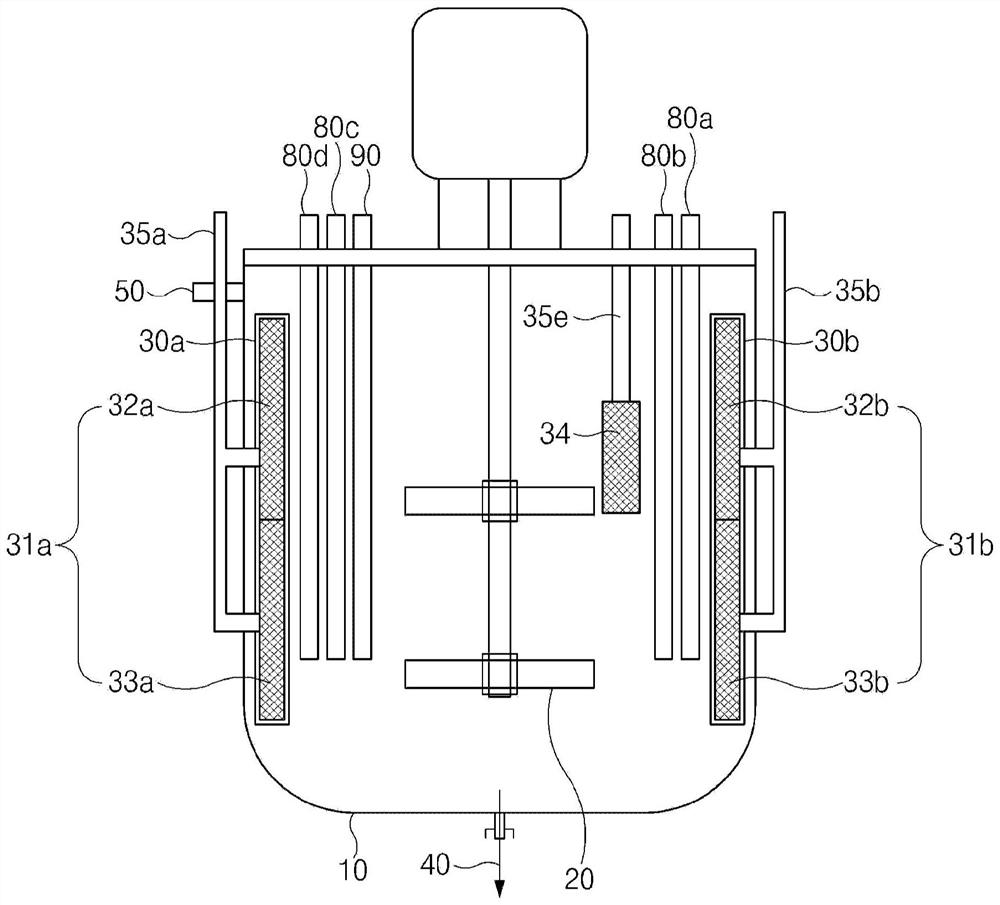

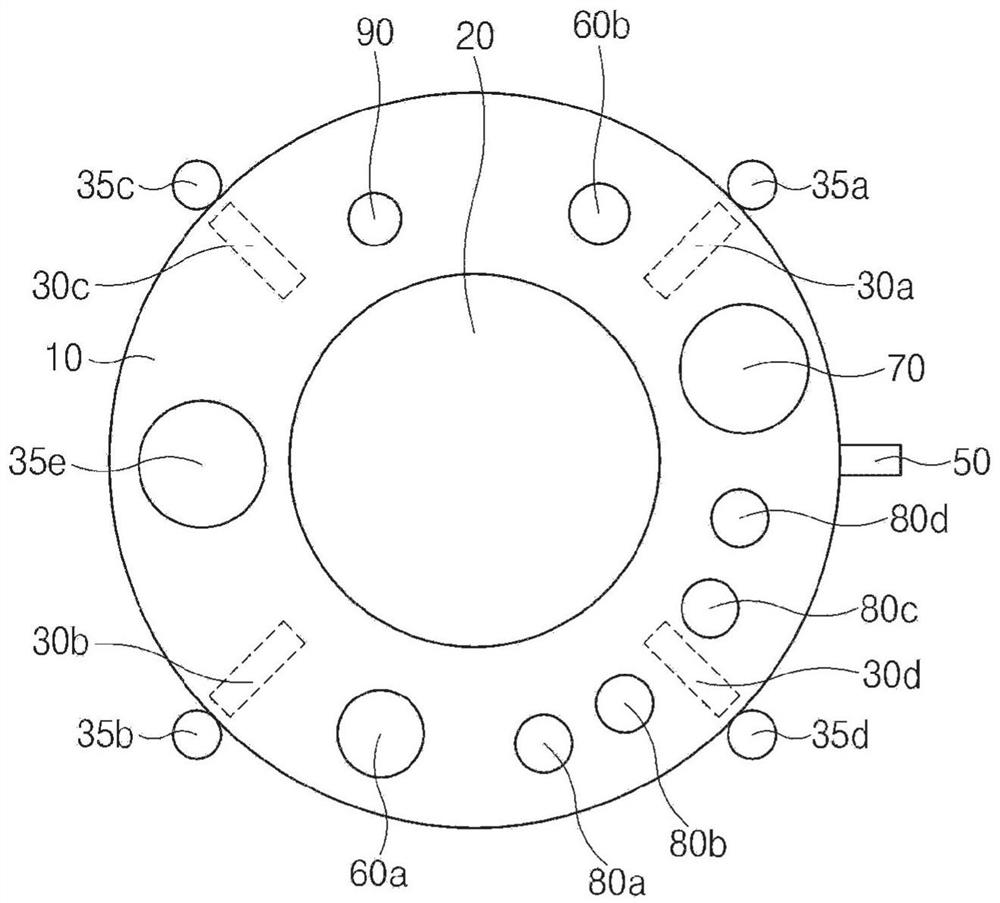

[0132] manufacture figure 1 and figure 2 The apparatus used to fabricate cathode active material precursors shown in .

[0133] Specifically, in a reactor having a volume of 70 L, four filter-type baffles including stainless steel filters with a pore diameter of 0.1 μm were installed at constant intervals on the outer wall of the reactor. The filter contained in the filter-type baffle consists of an upper filter and a lower filter that can operate independently. The length of the filter type baffle is 65% of the total height of the reactor, and the lower filter is set at 15% to 50% of the reactor height, and the upper filter is set at 50% to 85% of the reactor height at %. In addition, an additional filter made of metal (stainless steel) having a pore diameter of 5 μm was inserted into the reactor, and ...

Embodiment 2

[0140] Embodiment 2: the manufacture of cathode active material precursor

[0141] 1. Manufacture of equipment for the manufacture of cathode active material precursors

[0142] The apparatus for manufacturing a cathode active material precursor of Example 2 was manufactured in the same manner as in Example 1 except that no additional filter and additional reaction solution discharge line were installed in the manufacturing apparatus of Example 1.

[0143] 2. Fabrication of cathode active material precursors

[0144] NiSO 4 、CoSO 4 and MnSO 4 Nickel:cobalt:manganese was mixed in water in such an amount that the molar ratio of nickel:cobalt:manganese was 8:1:1 to prepare a transition metal-containing solution with a concentration of 2.4M.

[0145] Prepare the transition metal-containing solution, NaOH aqueous solution with a concentration of 25% by weight and NH with a concentration of 9% by weight 4 OH aqueous solution and introduce it into the reactor through the reactio...

experiment example 1

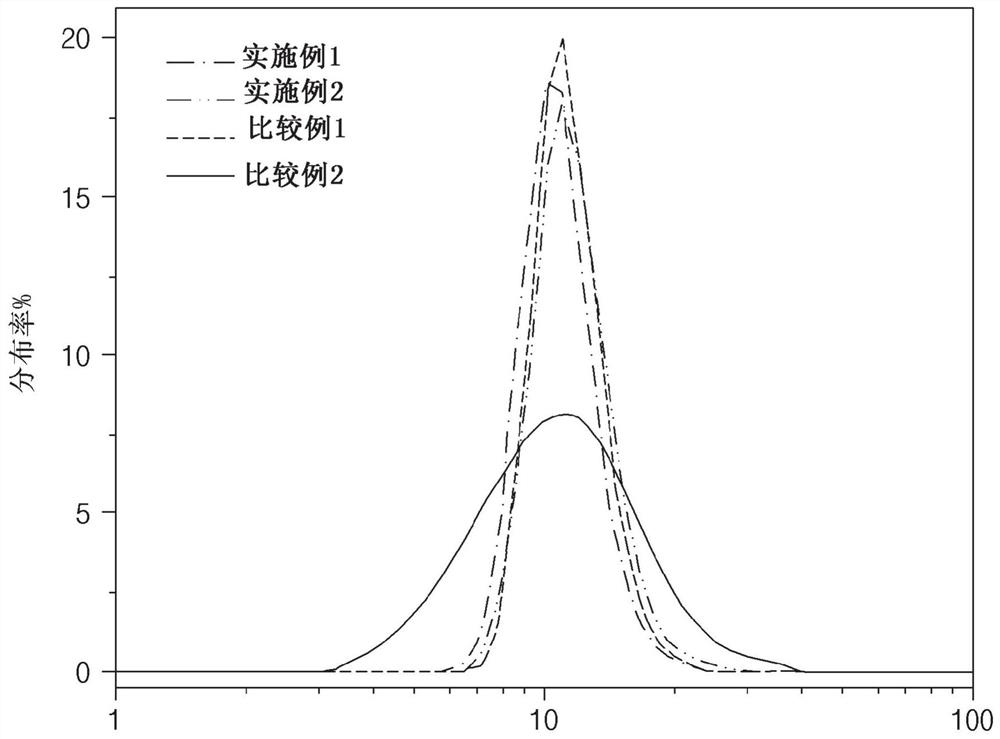

[0164] Experimental example 1: Evaluation of particle size distribution

[0165] In order to confirm the particle size distribution of the positive electrode active material precursor particles produced in Examples 1 and 2 and Comparative Examples 1 and 2, the S-3500 from Microtrac was used to measure the particles produced in Examples 1 and 2 and Comparative Examples 1 and 2. The particle size of the cathode active material precursor, and the results are shown in the following table 1 and image 3 middle.

[0166] [Table 1]

[0167] D. 5 (μm)

D. 50 (μm)

D. 95 (μm)

(D 95 -D 5 ) / D 50

Example 1 7.8 10.2 14.6 0.68 Example 2 8.1 10.9 15.8 0.70 Comparative example 1 8.2 10.7 15.0 0.63 Comparative example 2 5.0 10.2 20.1 1.48

[0168] Refer to Table 1 and image 3 , it was confirmed that the cathode active material precursor manufactured in the manufacturing apparatus of the example had a narrower parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com