A method for measuring dynamic liquid level in oil wells based on normalized convolution and adaptive filtering

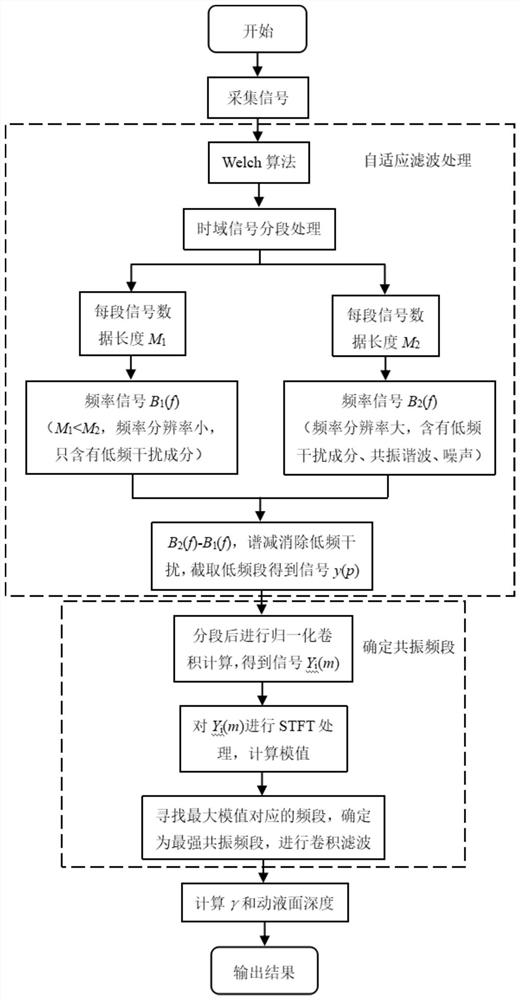

An adaptive filtering and normalization technology, applied in surveying, earth-moving drilling, wellbore/well components, etc., can solve the difficulty in realizing automatic calculation of dynamic fluid level value, difficulty in realizing dynamic fluid level measurement, and difficulty in resonating harmonic signals. and other problems, to improve the measurement accuracy and measurement range, the filtering effect is stable and reliable, and the effect of automatic calculation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, the above steps are further described.

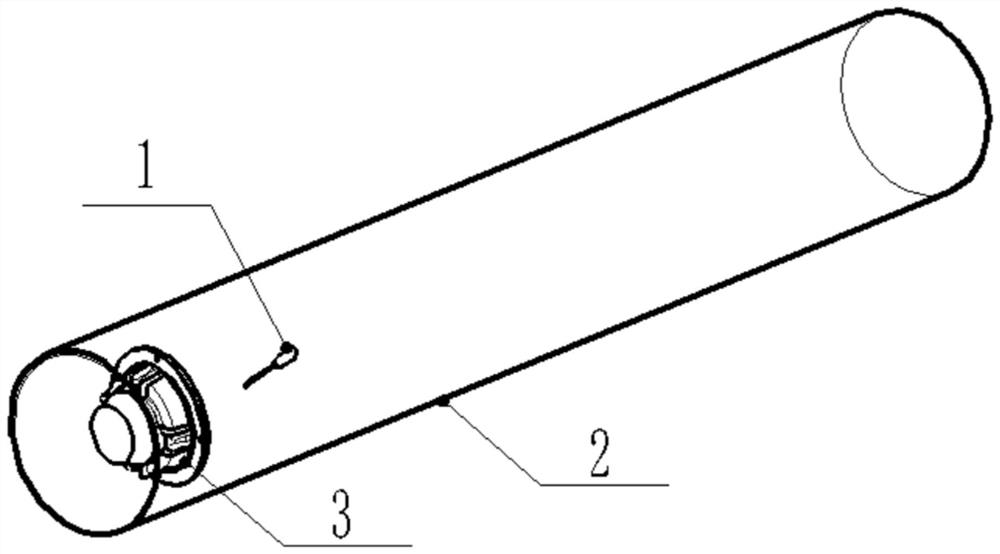

[0067] Install detection devices such as figure 2 , the loudspeaker 3 is installed at the pipe mouth, the acoustic sensor 1 is installed at the front end of the loudspeaker, and the distance from the loudspeaker 3 is 40cm, and the acoustic sensor 1 and the loudspeaker 3 are both flush with the axis of the casing 2, the experimental pipe diameter d=406mm, the actual pipe The length is 806.92m, and the end of the pipe is rigidly closed.

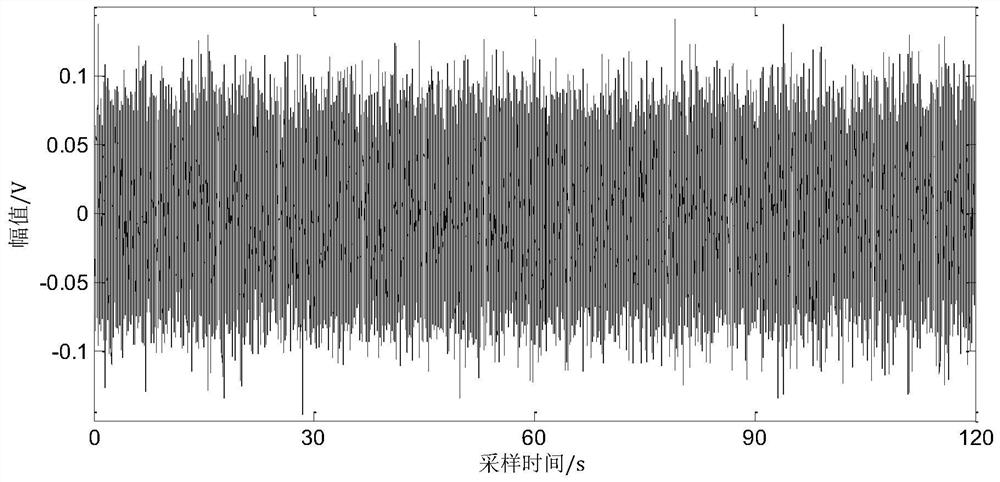

[0068] Set the signal sampling frequency f s = 2048Hz, sampling time t 1 =120s, the experimental environment temperature T=20℃. The acoustic sensor 1 collects the resonance signal of the air column, and the time domain signal is such as image 3 As shown, the useful signal is completely drowned out by the low frequency noise emitted by the loudspeaker 3 .

[0069] For the signal x(n) collected by the acoustic sensor 1, different segment numbers are selected for power spec...

Embodiment 2

[0087] In engineering applications, it is also a common requirement to reduce the amount of calculation data, reduce the hardware cost, and improve the calculation efficiency. This embodiment will compare the measurement time. Set the signal sampling frequency f s = 2048Hz, sampling time t 2 = 40s, the experimental environment temperature T = 20 ℃, the time domain signal such as Figure 12 shown;

[0088] The processing steps of the traditional algorithm are the same as those of the traditional signal x(n) collected by the acoustic sensor (1) in Embodiment 1. The process of using the traditional algorithm to process is the same. The STFT three-dimensional spectrum analysis is performed on the high-pass filtered signal. Figure 13 It can be seen that when the length of the available calculation data is reduced, there is no frequency distribution with strong energy in the three-dimensional spectrum, and the resonance harmonic frequency band is completely submerged by the noise...

Embodiment 3

[0094] This embodiment proposes an oil well dynamic liquid level measurement device based on normalized convolution and adaptive filtering, including a data acquisition module, an adaptive filtering processing module, a resonance frequency band confirmation module, and an oil well liquid level calculation module, wherein:

[0095] The data acquisition module includes a loudspeaker and an acoustic sensor, the loudspeaker is installed at the casing opening, the acoustic sensor is installed near the loudspeaker, and both the acoustic sensor and the loudspeaker are flush with the casing axis;

[0096] The loudspeaker is used to emit low-frequency noise to excite the air column in the pipe;

[0097] The acoustic sensor is used to collect the mixed signal of the noise emitted by the loudspeaker and the resonance of the air column;

[0098] The adaptive filtering processing module includes a Welch-based signal selection module, a signal conversion module and a spectral subtraction mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com