Embedded steel plate reinforced engineering bamboo component and preparation method thereof

An engineering bamboo and engineering technology, applied in the field of improving the flexural strength and flexural stiffness of engineering bamboo components, can solve problems such as insufficient flexural stiffness, and achieve the effects of excellent bearing performance, improved material utilization, and reduced component cross-sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

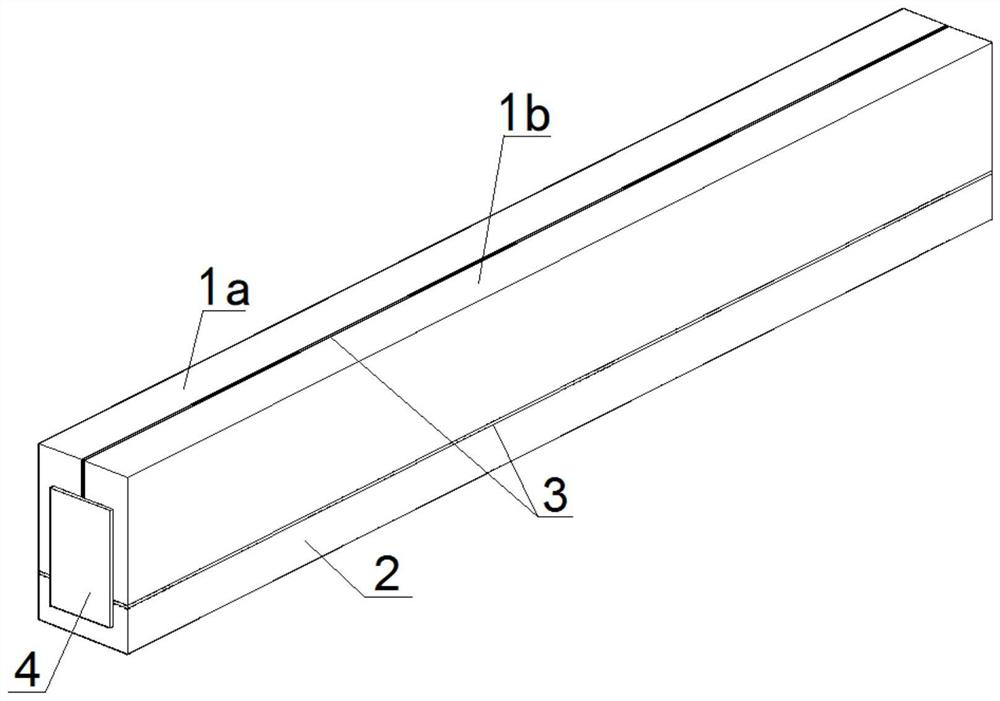

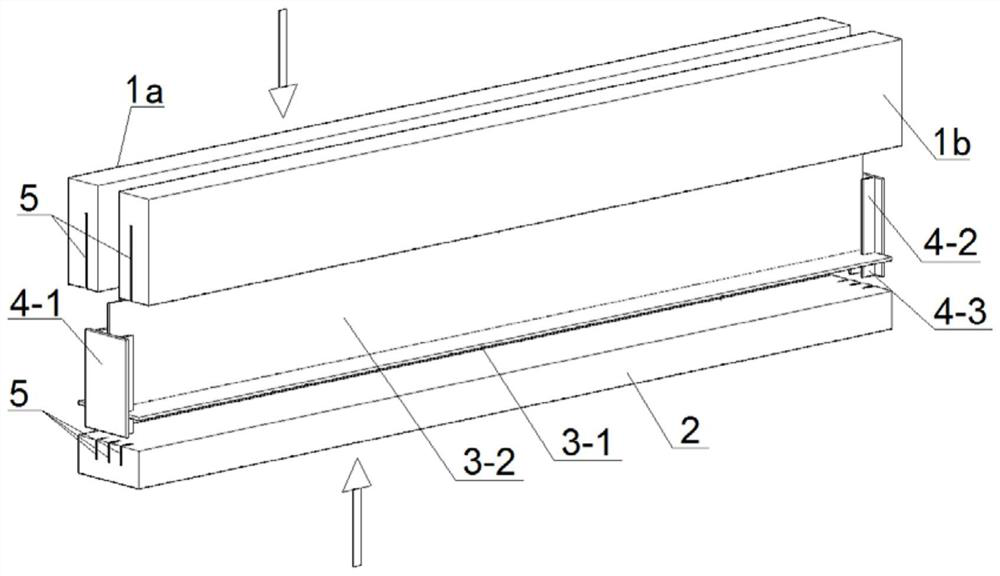

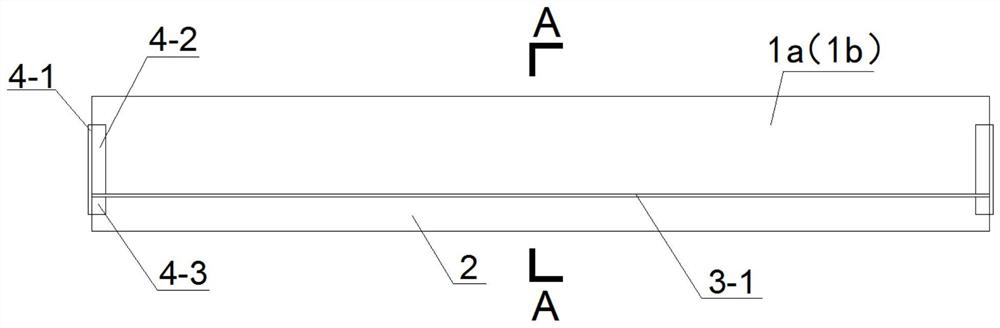

[0025] combine Figure 1 to Figure 4 As shown, an engineered bamboo component reinforced with embedded steel plates includes a left engineering bamboo rectangular block 1a, a right engineering bamboo rectangular block 1b, a bottom engineered bamboo rectangular block 2, a T-shaped steel plate 3 and welded on both ends of the T-shaped steel plate. Two shear parts4.

[0026] The cross-sectional size of the left and right engineering bamboo rectangular blocks is 87mm * 217mm, and the cross-sectional dimension of the bottom engineering bamboo rectangular block 2 is 180mm * 77mm. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com