Control method and system for CAS-OB refining automatic alloying

A control method and alloy technology, which is applied in the field of metallurgy, can solve problems such as unqualified ingredients, errors, and unreasonable input of alloy additions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0065] The invention provides a CAS-OB refining automatic alloying control method, which uses a secondary system to predict the composition of the arrival station, automatically calculate the amount of alloy added according to the composition of the arrival station, automatically perform feeding and preparation, and automatically complete the alloying operation , and predict the end composition according to the arrival composition and the actual alloy addition amount, which improves the efficiency of CAS-OB refining and alloying.

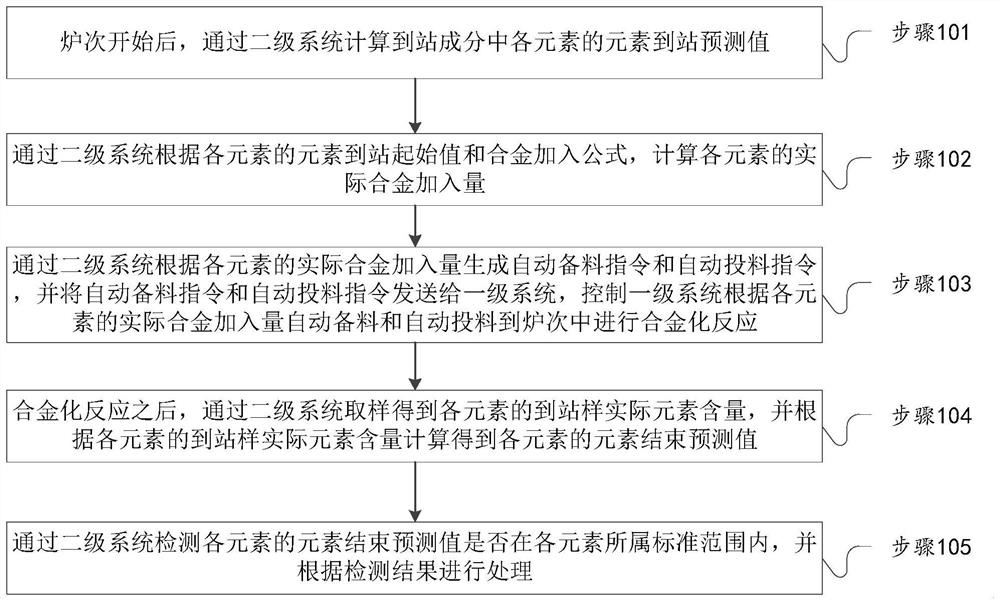

[0066] see below figure 1 , the method includes the following steps:

[0067] Step 101, after the heat starts, calculate the element arrival prediction value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com