Wafer cutting fluid containing natural plant extracts

A technology of natural plants and extracts, used in lubricating compositions, petroleum industry, etc., can solve the problems of residue/particle accumulation, static electricity accumulation, metal corrosion, etc., and achieve the effect of inhibiting electrochemical corrosion and improving electron density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

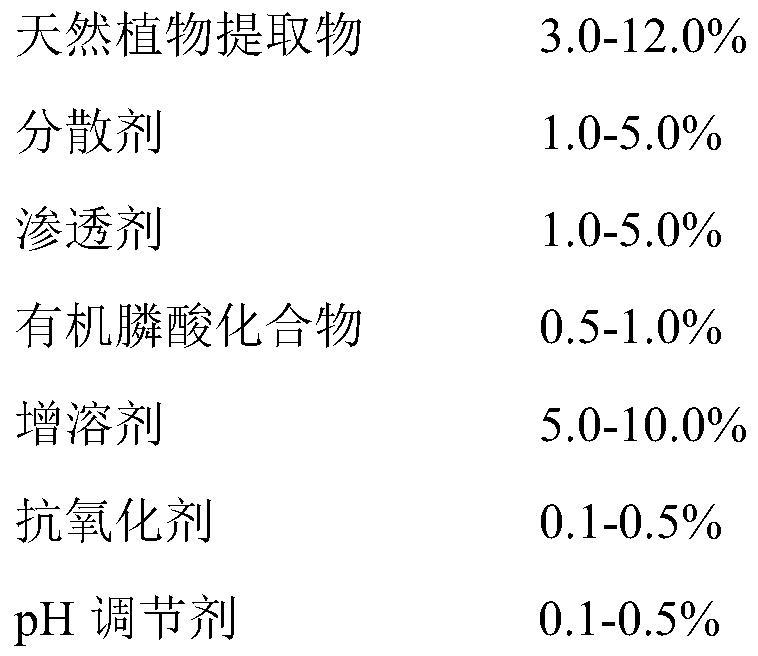

[0023] The preparation method of embodiment 1-12 is: add a certain amount of ultrapure water in the reactor, start stirring; add the natural plant extract according to the mass ratio, stir for 5 minutes; add the dispersant according to the mass ratio, stir for 5 minutes; Add penetrating agent and stir for 5 minutes; add organic phosphoric acid compound according to mass ratio, stir for 5 minutes; add solubilizer according to mass ratio, stir for 5 minutes; add antioxidant according to mass ratio, stir for 5 minutes; finally add pH adjustment according to mass ratio agent, stirred for 20 minutes, until transparent, that is, the wafer cutting liquid.

[0024] Table 1 Components and contents of the cutting fluid of Examples 1-12

[0025]

[0026]

[0027]

Embodiment 11

[0034] The detection of embodiment 11 metal corrosion

[0035] The effect detection of the following examples all adopts the following method: cut 12-inch AlDummy wafer with Disco 6362 wafer cutting machine, and the dilution factor of cutting fluid is 3000 times, after cutting, the wafer is placed in the air, respectively in 8 hours, 12 hours, Observe the surface corrosion for 24 hours and 36 hours.

[0036] Table 2 The particle residue results of Examples 1-10 and Comparative Example 1

[0037]

[0038] Among them: NG stands for: unqualified, OK: qualified.

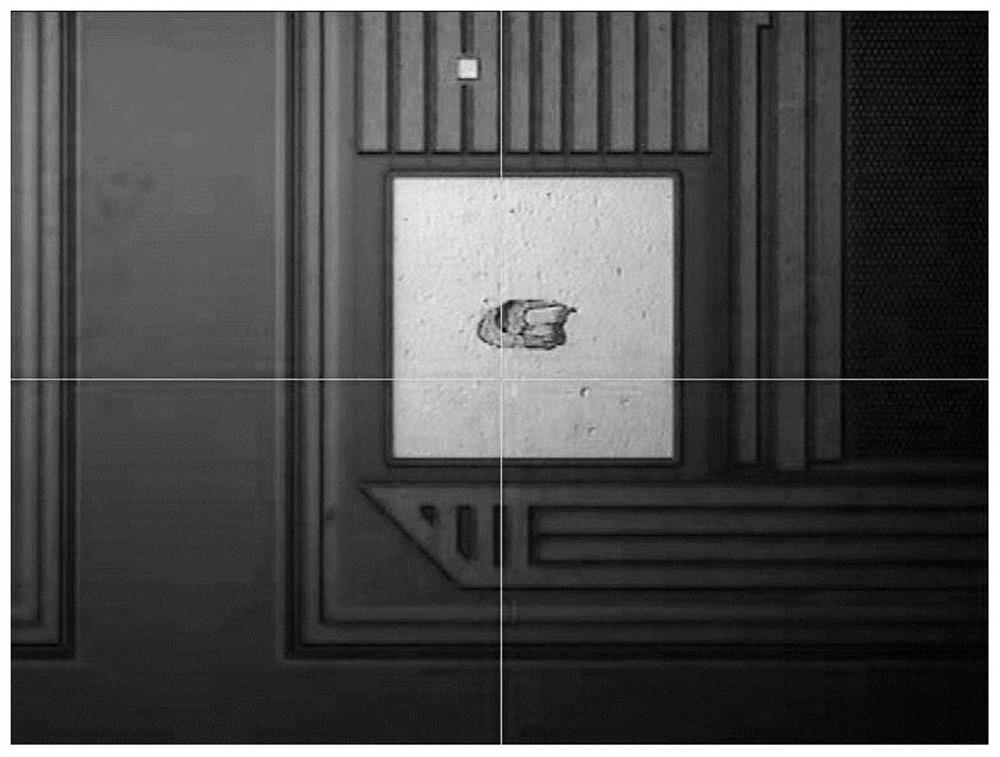

[0039] With or without corrosion comparison picture figure 1 and figure 2 as shown, figure 1 It is the wafer surface after metallographic microscope observation after cutting in embodiment 1 after cutting, and the visible wafer Al Pad surface is not corroded in the figure; figure 2 It is the surface of the wafer cut by the cutting fluid in Comparative Example 1, and the Al Pad part circled in the figure has obv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com