Laser pipe cutting machine feeding device suitable for various pipes and working method of laser pipe cutting machine feeding device

A pipe cutting machine and pipe material technology, applied in auxiliary devices, laser welding equipment, applications, etc., can solve the problem that laser pipe cutting and feeding devices cannot be applied to various pipe materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

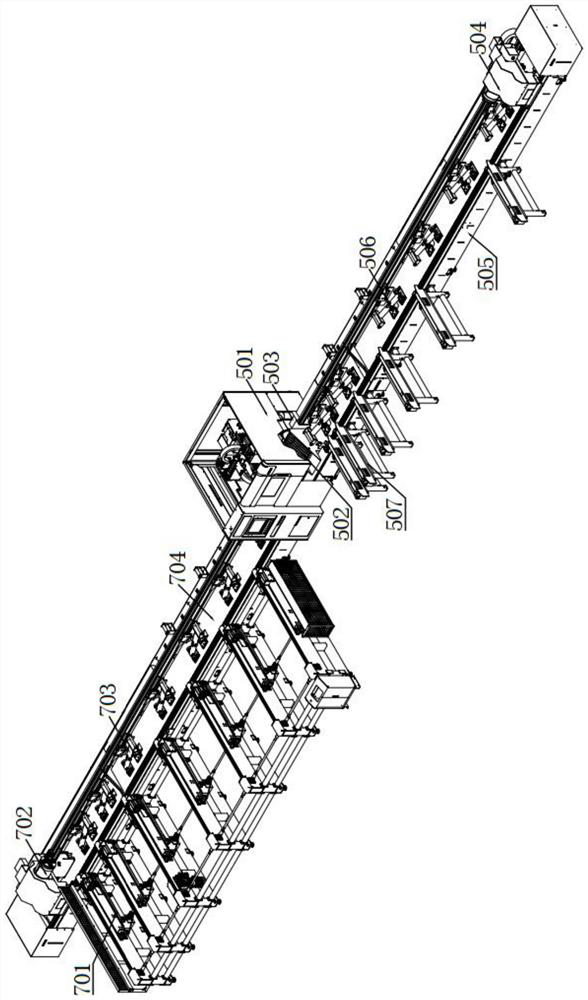

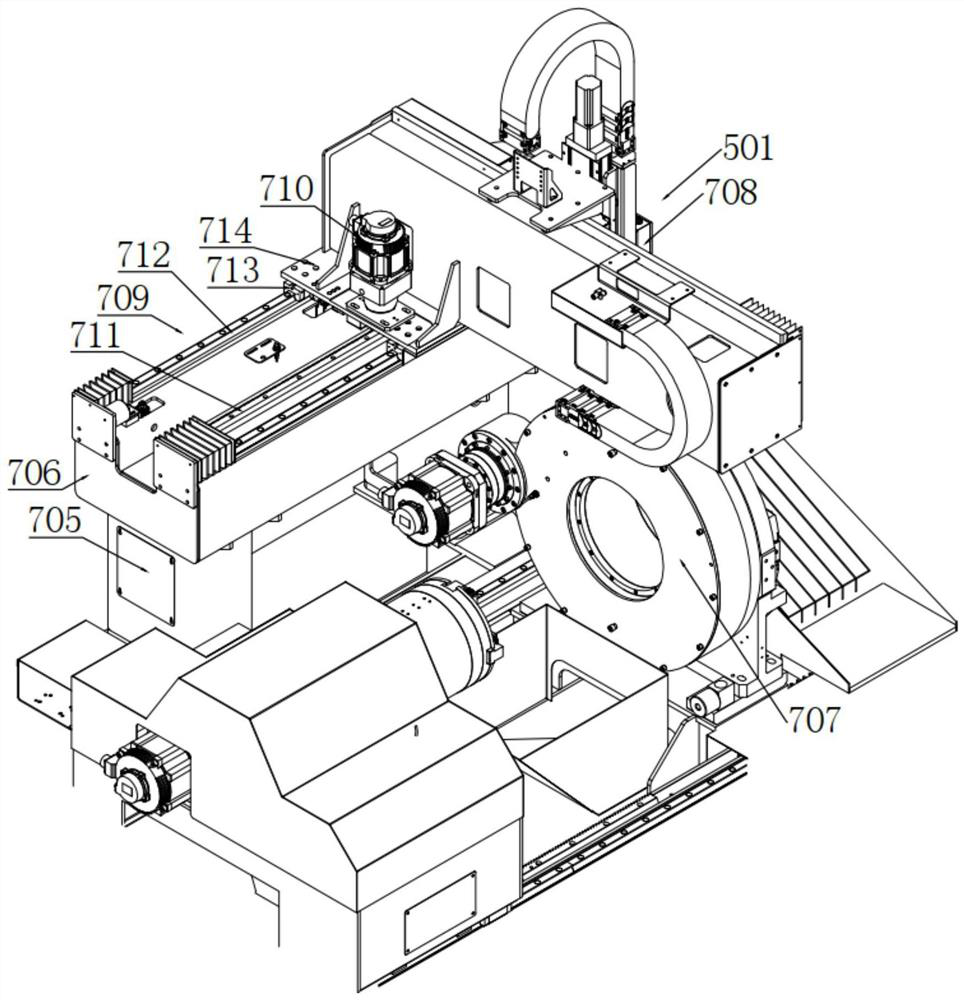

[0060] like Figure 1-4 The shown laser pipe cutting machine feeding device suitable for various pipe materials, such as figure 1 The fully automatic double-station intelligent laser pipe cutting machine shown includes a feeding unit 701, a feeding chuck 702, a feeding floating support unit 703, a pipe cutting machine feeding machine 704, a pipe cutting machine main body 501, and a blanking unit 502, dust removal unit 503, receiving chuck 504, pipe cutting machine unloading machine 505, unloading hosting unit 506 and unloading unit 507, the pipe cutting machine feeding machine 704 and pipe cutting machine unloading machine 505 They are respectively arranged on the feed side and the discharge side of the main body 501 of the pipe cutting machine. The feeding chuck 702 and the feeding floating support unit 703 are both arranged on the feeding table 704 of the pipe cutting machine. The feeding unit 701 is located at the cutting machine. On one side of the pipe machine loading ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com