Flame-retardant structure, preparation method thereof and lithium battery structure

A kind of flame retardant, organic technology, used in the field of flame retardant structure and its preparation, lithium battery structure, can solve the problems of thermal safety, battery thermal runaway and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

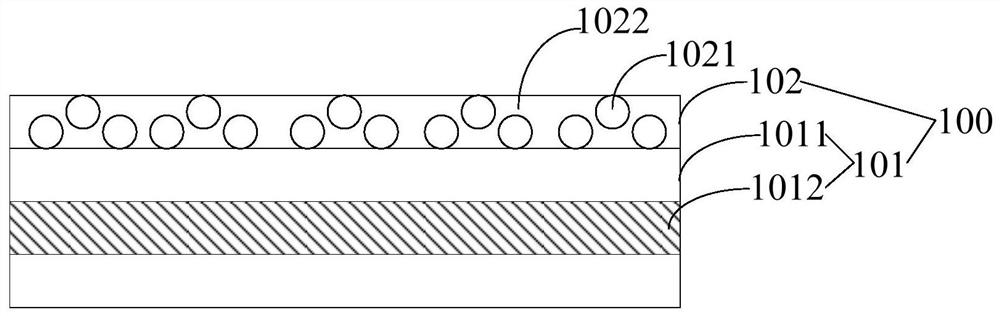

[0040] refer to figure 1 , this embodiment provides a flame retardant structure 100, the flame retardant structure 100 includes a flame retardant membrane layer 101 and a polyethylene microsphere film layer 102.

[0041] The flame retardant membrane layer 101 includes an organic polymer layer 1011 and a flame retardant 1012 disposed in the organic polymer layer 1011 . Specifically, the flame retardant membrane layer 101 may be a fiber membrane with a shell-core structure, the organic polymer layer 1011 is the shell, and the flame retardant 1012 inside the organic polymer is the core. The fiber structure can be prepared by electrospinning process. When a certain high temperature condition is met, the organic polymer layer 1011 melts, and the internal flame retardant 1012 is released, so that the environment where the flame retardant structure 100 is located will not ignite or explode.

[0042] The polyethylene microsphere film layer 102 includes a mixture of polyethylene micr...

Embodiment 2

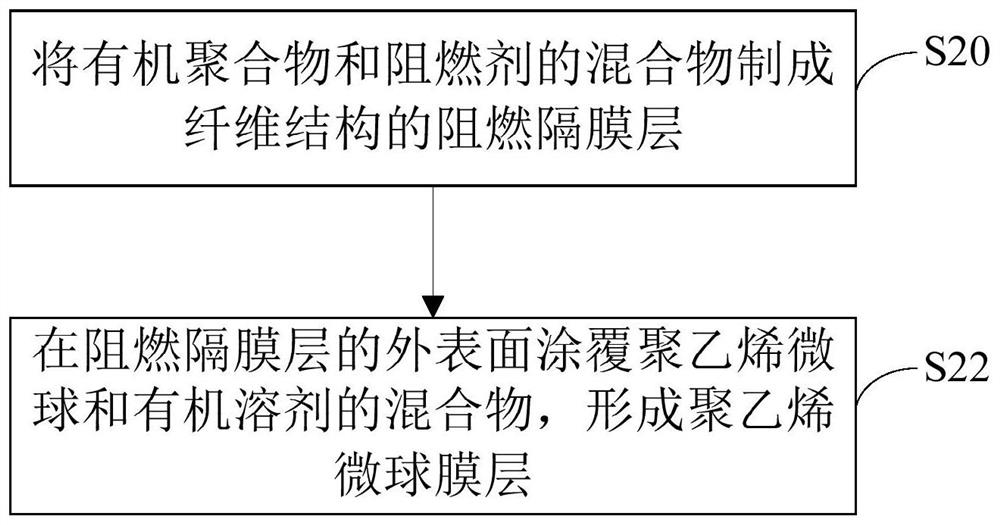

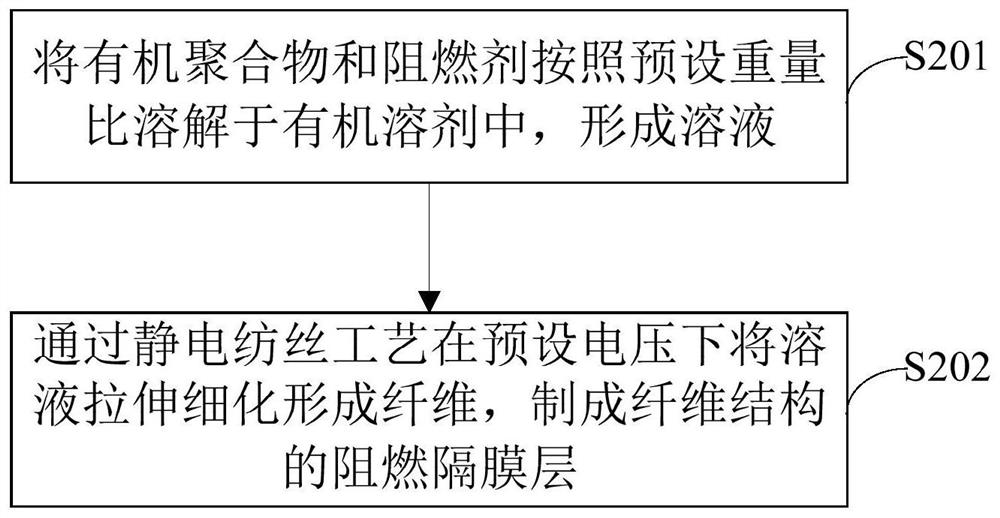

[0055] This embodiment provides a method for preparing a flame-retardant structure 100, referring to figure 2 , the preparation method of the flame retardant structure 100 includes the following steps:

[0056] Step S20 , making the mixture of the organic polymer and the flame retardant 1012 into a flame retardant membrane layer 101 with a fibrous structure.

[0057] The formed flame retardant membrane layer 101 is a fiber membrane with shell-core structure, the organic polymer is the shell, and the flame retardant 1012 inside the organic polymer is the core. The fiber structure can be prepared by electrospinning process. When a certain high temperature condition is met, the organic polymer layer 1011 melts, and the flame retardant 1012 inside is released, so that the environment where the flame retardant structure 100 is located does not catch fire or explode, avoiding thermal safety problems.

[0058] Step S22 , coating the mixture of polyethylene microspheres 1021 and or...

Embodiment 3

[0078] This embodiment provides a lithium battery structure, with reference to Figure 4 , the lithium battery structure includes a positive electrode 200 , a negative electrode 300 and a flame retardant structure 100 .

[0079] The flame retardant structure 100 is arranged between the positive electrode 200 and the negative electrode 300. The flame retardant structure 100 includes a flame retardant membrane layer 101 and a polyethylene microsphere film layer 102 arranged on the outer surface of the flame retardant membrane layer 101. The flame retardant membrane layer 101 includes organic The polymer layer 1011 and the flame retardant 1012 disposed in the organic polymer layer 1011 , the polyethylene microsphere film layer 102 includes a mixture of polyethylene microspheres 1021 and an organic solvent 1022 . Wherein, the polyethylene microsphere film layer 102 can be arranged on the outer surface of the side of the flame-retardant membrane layer 101 facing the negative electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com