Copper foil composite material, preparation method thereof, negative pole piece and lithium ion battery

A composite material and copper foil technology, which is applied in battery electrodes, secondary batteries, metal material coating processes, etc. Industrialized production, alleviation of chalking problems, and the effect of strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

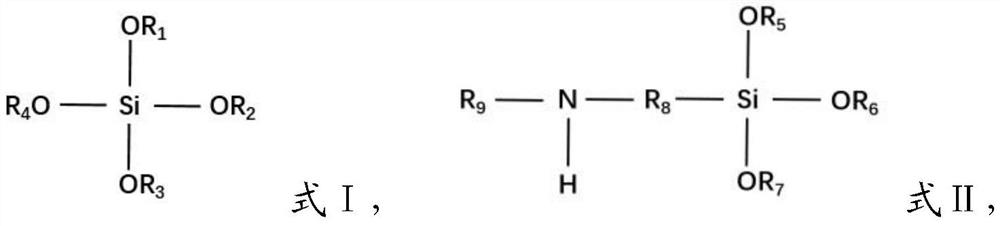

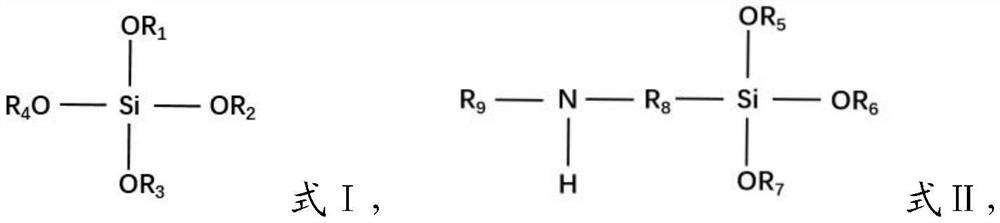

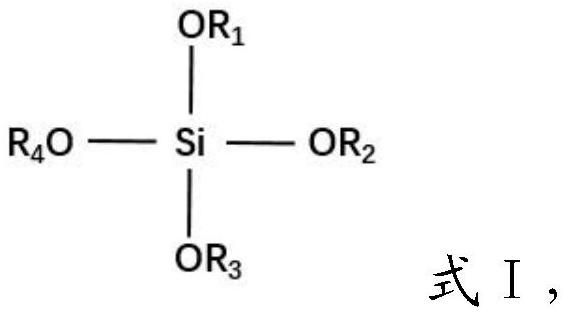

Method used

Image

Examples

Embodiment 1

[0066] S1) Preparation of copper foil composite material A1:

[0067] Dissolve 5ml of N-(aminoethyl)-γ-aminopropyltrimethoxysilane and 5ml of deionized water in 90ml of absolute ethanol solution, and react with constant stirring at 20°C for 90min to obtain a volume fraction of 5% aminosilane coupling agent solution; soak the copper foil in the obtained solution, take it out after 2 minutes, and then place it at 100° C. for 1 hour in vacuum treatment to obtain the copper foil composite material, denoted as A1.

[0068] S2) making of pole piece N1:

[0069] Mix 15 parts by mass of polyacrylic acid (abbreviated as PAA), 15 parts by mass of binder Super P and 70 parts by mass of active material nano-silicon with a mortar, then add 0.2ml of secondary water to obtain negative electrode slurry ; Evenly coat the negative electrode slurry on the modified copper foil composite material A1, and the solid coating amount is 1mg / cm 2 , and then dried in a vacuum oven at 100° C. for 12 hou...

Embodiment 2

[0075] S1) Preparation of copper foil composite material A2:

[0076] Dissolve 3ml of N-(aminoethyl)-γ-aminopropyltrimethoxysilane and 3ml of deionized water in 94ml of absolute ethanol solution, and react with constant stirring at 20°C for 90min to obtain a volume fraction of 3% aminosilane coupling agent solution; soak the copper foil in the obtained solution, take it out after 2 minutes, and then place it at 100° C. for 1 hour in vacuum treatment to obtain the copper foil composite material, which is designated as A2.

[0077] S2) making of negative electrode sheet N2:

[0078] Mix 15 parts by mass of polyacrylic acid (abbreviated as PAA), 15 parts by mass of binder Super P and 70 parts by mass of active material nano-silicon with a mortar, then add 0.2ml of secondary water to obtain negative electrode slurry ; Evenly coat the negative electrode slurry on the modified copper foil composite material A2, and the solid coating amount is 1mg / cm 2 , and then dried in a vacuum ...

Embodiment 3

[0082] S1) Preparation of copper foil composite material A3:

[0083] Dissolve 1ml of N-(aminoethyl)-γ-aminopropyltrimethoxysilane and 1ml of deionized water in 98ml of absolute ethanol solution, and react with constant stirring at 20°C for 90min to obtain a volume fraction of 1%. aminosilane coupling agent solution; soak the copper foil in the obtained solution, take it out after 2 minutes, and then place it at 100°C for 1 hour in vacuum treatment to obtain the copper foil composite material, which is designated as A3.

[0084] S2) making of pole piece N3:

[0085] Mix 15 parts by mass of polyacrylic acid (abbreviated as PAA), 15 parts by mass of binder Super P and 70 parts by mass of active material nano-silicon with a mortar, then add 0.2ml of secondary water to obtain negative electrode slurry ; Evenly coat the negative electrode slurry on the modified copper foil composite material A3, the solid coating amount is 1mg / cm 2 , and then dried in a vacuum oven at 100° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com