Welding structural part process optimization method and system based on industrial AI technology

A welding structure and process optimization technology, applied in welding equipment, neural learning methods, design optimization/simulation, etc., to achieve the effects of maintaining product quality, improving product consistency, and good training effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

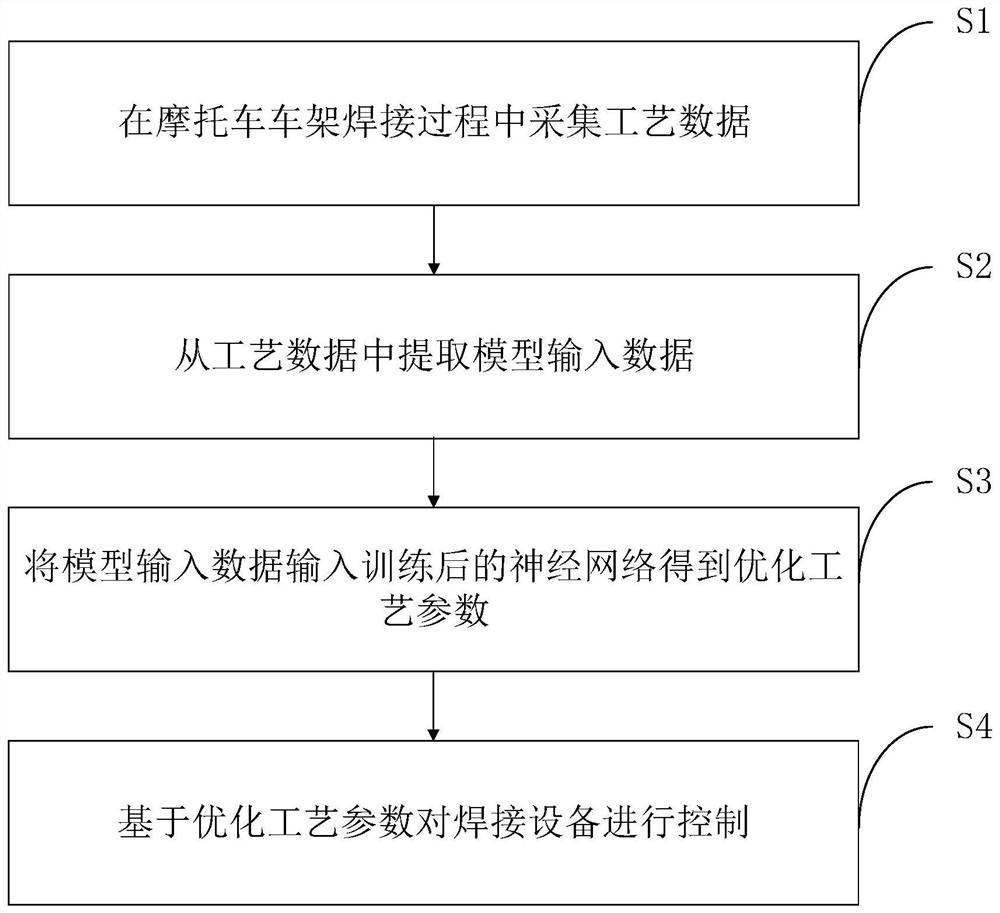

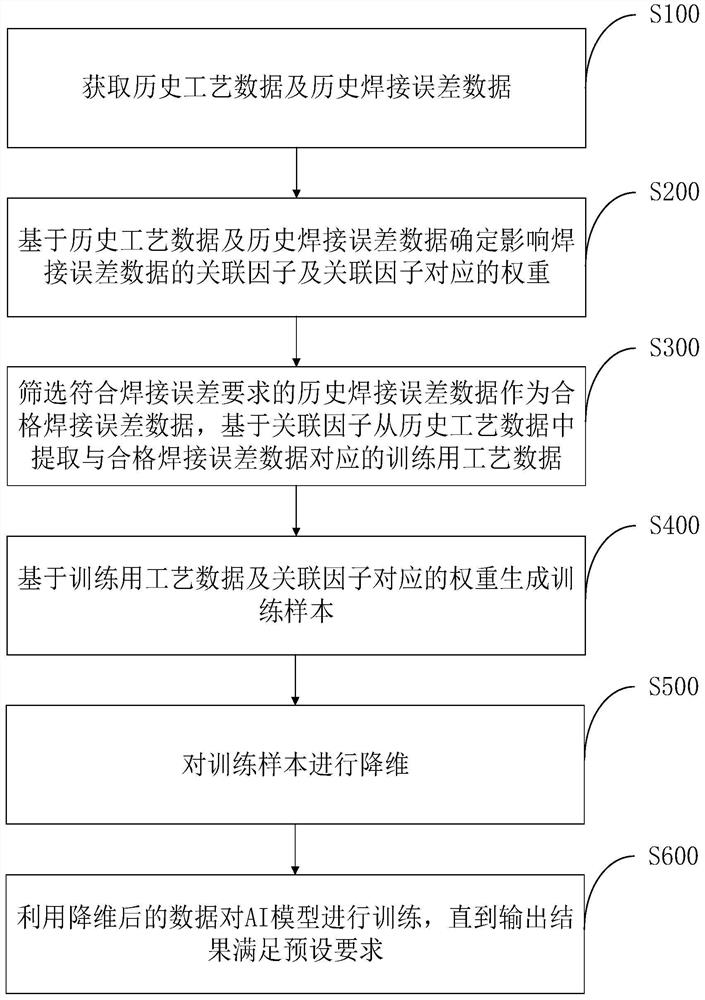

[0044] Such as figure 1 As shown, the present invention discloses a process optimization method for welded structural parts based on industrial AI technology, including:

[0045] S1. Collect process data during the motorcycle frame welding process;

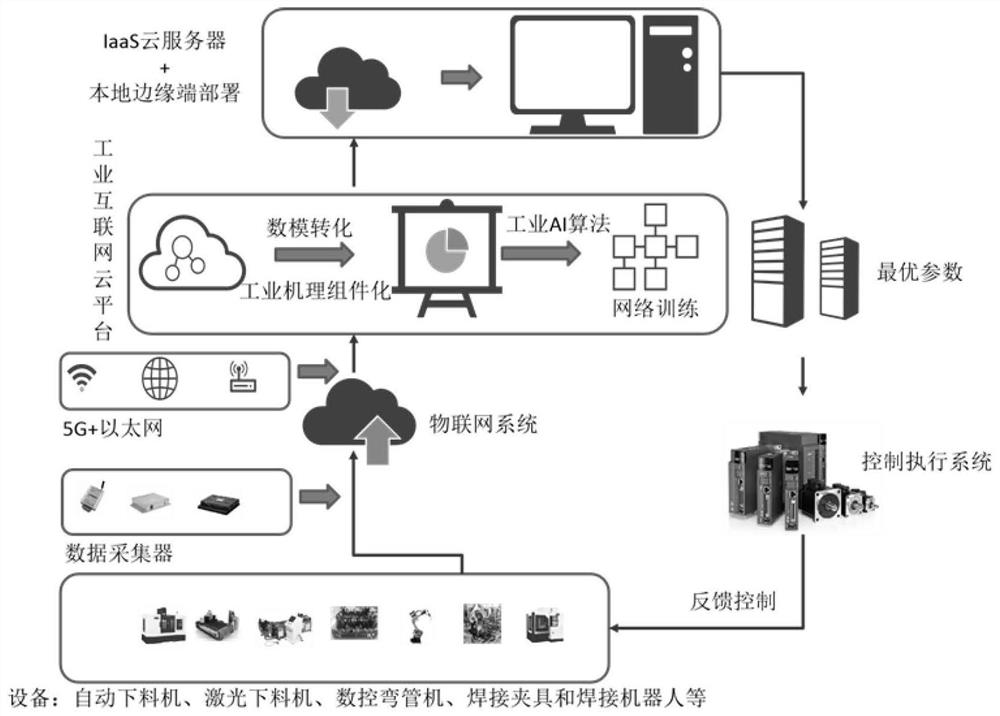

[0046] Through the IOT data collection of the motorcycle frame welding process, various process data can be obtained. Due to the dispersion of information collection nodes and the size of information flow, data transmission mainly uses 5G+Ethernet as the transmission form. Through this form, the scattered node data is transmitted to the Internet of Things terminal in a complete, safe and timely manner, and then transmitted to the industrial Internet cloud platform for subsequent data model processing.

[0047] S2. Extract associated feature data from process data;

[0048] In the present invention, for the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com