Organic solid waste self-maintaining smoldering treatment method based on in-furnace catalytic oxidation

A technology of catalytic oxidation of organic solid waste, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of increasing the complexity of the process system and implementation cost, improving flue gas purification, and high combustible gas components, so as to reduce smoke Gas purification requirements, realization of transmission rate, and the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

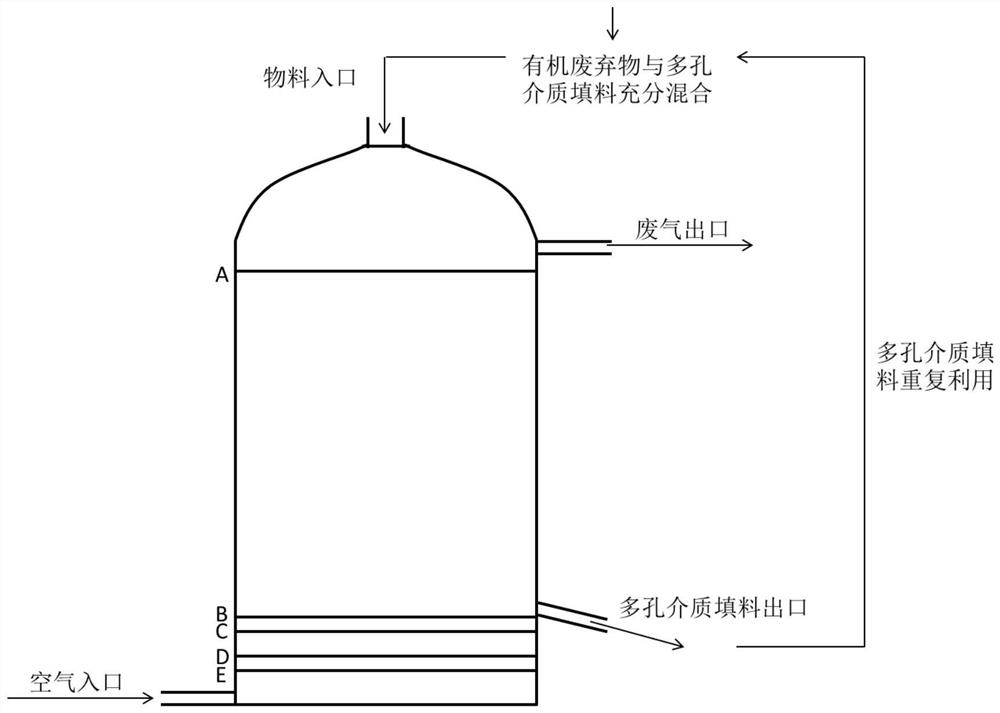

Method used

Image

Examples

Embodiment 1

[0034] The municipal sludge with a water content of 80% is disposed of through a smoldering device, and the sludge, sand, and platinum-supported catalyst (particle size 1mm to 2mm) are uniformly mixed by physical stirring at a mixing ratio of 20%, 76%, and 4%. Send it into the smoldering reaction device through the feeder, and then turn on the heating. When the temperature of the bottom layer of mixed material reaches 250°C, start the air supply. The Darcy flow rate of the air in the furnace is 3.5cm / s. After about 20 minutes of air supply, turn off the heating. Continue the air supply until all the filling materials in the furnace are disposed of, that is, the temperature of the uppermost layer of the filling materials in the furnace reaches above 350°C. By adding a catalyst, the concentration of carbon monoxide in the flue gas can be reduced by about 78%, and the smoldering reaction rate can be increased by about 18%.

Embodiment 2

[0036] The municipal sludge with a water content of 80% is disposed of by a smoldering device, and the sludge, sand, and manganese-cobalt catalysts (0.5 mm to 1 mm in particle size) loaded on diatomaceous earth or alumina particles are mixed with 14.3%, 81.4%, 4.3 The mixing ratio of % is uniformly mixed by physical stirring, and after mixing, it is sent to the smoldering reaction device through the feeder, and then the heating is turned on. When the temperature of the mixed material at the bottom layer reaches 280°C, the air supply is started, and the Darcy flow rate of the air in the furnace is 4.5 cm / s, turn off the heating after supplying air for about 10 minutes, and continue to supply air until all the filling materials in the furnace are disposed of, that is, the temperature of the uppermost layer of filling materials in the furnace reaches above 350°C. By adding the catalyst, the concentration of carbon monoxide in the flue gas can be reduced by about 65%, and the smold...

Embodiment 3

[0038] Dispose of municipal sludge with a water content of 90% through a smoldering device, mix sludge, sawdust, sand, copper dichromate catalyst (particle size 0.5mm ~ 1.2mm) with 16%, 4%, 60%, 20% The ratio is uniformly mixed by physical stirring, and after mixing, it is sent to the smoldering reaction device through the feeder, and then the heating is turned on. When the temperature of the bottom mixed material reaches 300°C, the air supply is started, and the Darcy flow rate of the air in the furnace is 3.0cm / s , Turn off the heating after supplying the air for about 30 minutes, and continue to supply the air until all the filling materials in the furnace are disposed of, that is, the temperature of the uppermost layer of the filling materials in the furnace reaches above 350 °C. By adding a catalyst, the concentration of carbon monoxide in the flue gas can be reduced by about 76%, and the smoldering reaction rate can be increased by about 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com