Low-alloy, high-strength and high-weather-resistance structural steel for highway guardrails and preparation method thereof

A technology for highway guardrails and structural steel, which is applied in the direction of manufacturing tools, temperature control, heat treatment equipment, etc., can solve the problem of no high weather-resistant structural steel, etc., and achieve the effects of improving weather resistance, reducing usage, and improving weather resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

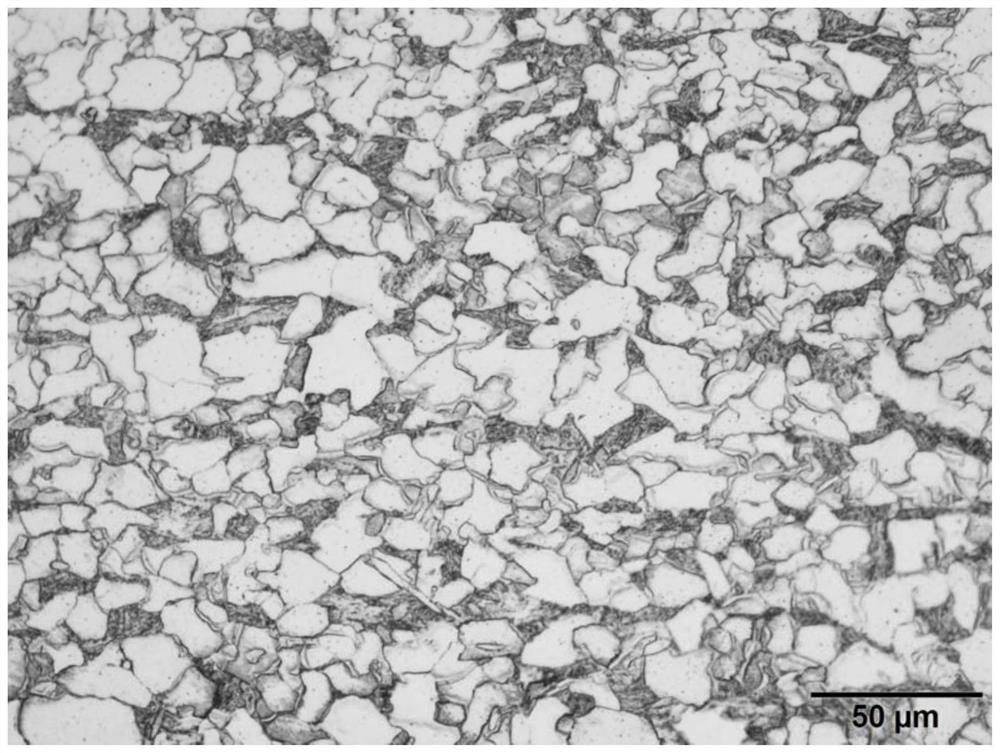

[0038] In Example 1, the weight loss rate of low-alloy, high-strength and high-weathering structural steel is 1.687g / (m 2 h), the atmospheric corrosion resistance index I is 8.402, and the ferrite grain size grade is 10.5.

Embodiment 2

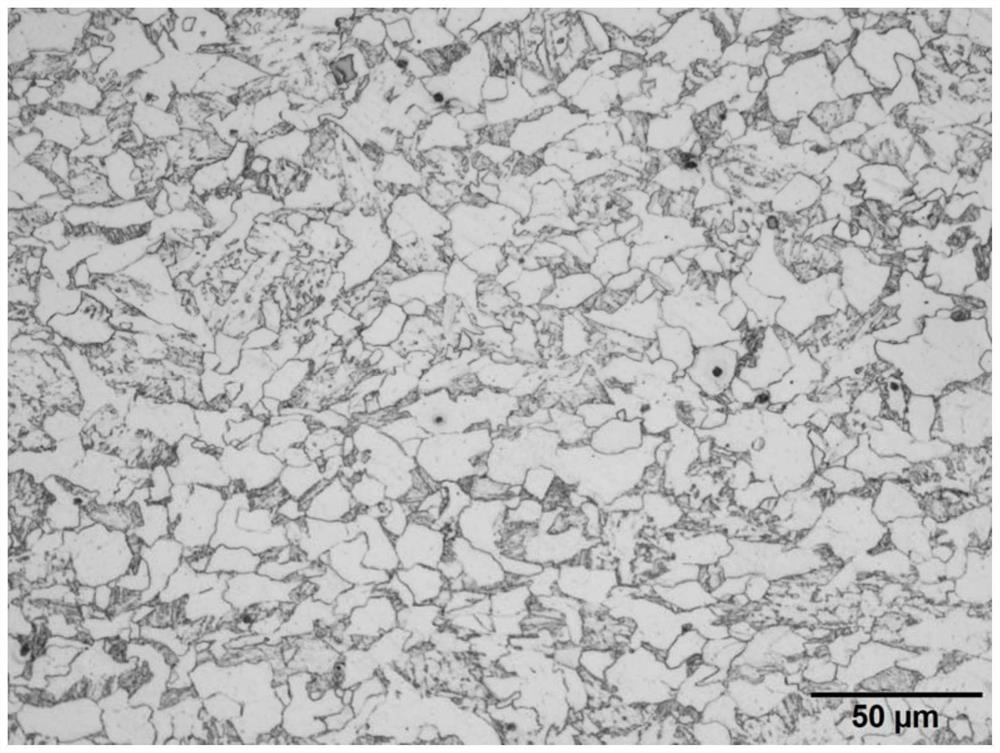

[0039] In Example 2, the 75-hour cycle immersion weight loss rate of low-alloy high-strength and high-weathering structural steel was 1.985g / (m 2 h), the atmospheric corrosion resistance index I is 8.145, and the ferrite grain size grade is 10.5.

[0040] The results of the examples show that the present invention can obtain higher strength and good plasticity by adding weather-resistant elements, refining grain elements and controlling other elements. Cr layer, so as to achieve a stable and dense rust layer, improve the weather resistance of structural steel, and meet the high-strength and high-weather resistance requirements for highway guardrails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com