High-transmittance anti-dazzle explosion-proof protective film and preparation method thereof

A high transmittance, protective film technology, applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problems of low definition, poor experience, low transmittance, etc., and achieve good visual effects , Reasonable structural design and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

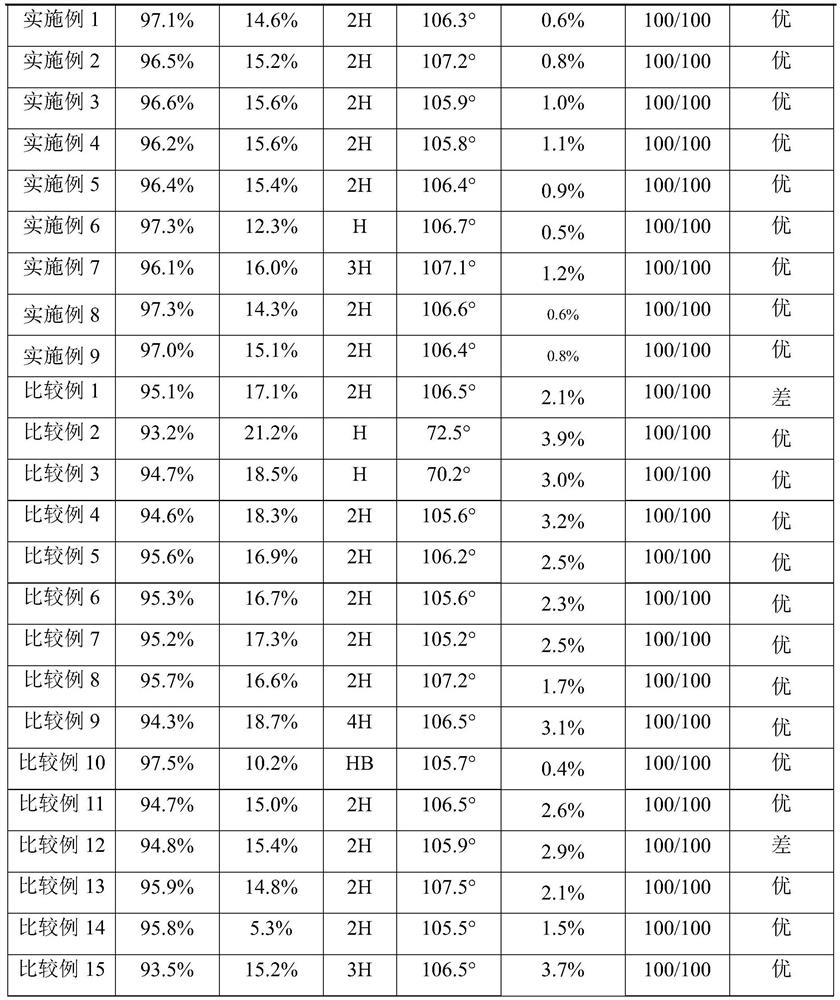

Embodiment 1

[0042] This embodiment 1 provides a high-transmittance anti-glare and explosion-proof protective film, including a substrate layer, which is sequentially coated with a recoatable anti-glare particle layer, a recoatable low refractive index layer and a non-recoatable layer from the front of the substrate layer upwards. Coat the low-refractive index layer, and coat the optical adhesive layer and the release film layer sequentially from the back of the substrate layer downwards.

[0043] The substrate layer is a TAC transparent substrate with a thickness of 40 μm, and the manufacturer is Fuji, Japan.

[0044] The recoatable anti-glare particle layer is composed of anti-glare particles and UV-curable resin, with a thickness of 3 μm; among them, the anti-glare particles are acrylic (polymethyl methacrylate) particles, specifically FPM-1 provided by Japan Arakawa Chemical ; The UV curing resin is epoxy acrylic resin FPB-6 provided by Arakawa Chemical in Japan.

[0045] The recoatab...

Embodiment 2

[0062] Embodiment 2 provides a high-transmittance anti-glare and explosion-proof protective film, which differs from Embodiment 1 only in that the thickness of the non-recoatable low-refractive index layer is 110 nm, and the parameters of other components are the same.

[0063] The preparation method of the high-transmittance anti-glare and explosion-proof protective film provided in this embodiment 2 is only different from that of embodiment 1 in that: the preparation of the non-recoatable low-refractive index layer coating liquid in step 3 is: coating SL037 The solution was diluted with propylene glycol methyl ether solvent to obtain a non-recoatable low-refractive index layer coating solution with a solid content of 2.2%, and the rest of the steps were the same.

Embodiment 3

[0065] Embodiment 3 provides a high-transmittance anti-glare and explosion-proof protective film. The only difference from Embodiment 1 is that the thickness of the non-recoatable low refractive index layer is 90 nm, and the parameters of other components are the same.

[0066] The preparation method of the high-transmittance anti-glare and explosion-proof protective film provided in this Example 3 is only different from Example 1 in that: the preparation of the non-recoatable low-refractive index layer coating liquid in Step 3 is: coating SL037 The solution was diluted with propylene glycol methyl ether solvent to obtain a non-recoatable low-refractive index layer coating solution with a solid content of 1.8%, and the rest of the steps were the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com