Spraying quick-setting rubber asphalt waterproof coating and preparation method thereof

A technology for quick-setting rubber asphalt and waterproof coatings, which can be used in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., and can solve the problems that rubber particles cannot be cross-linked again, and the performance of rubber-modified asphalt waterproof coatings is unfavorable. , to achieve the effect of improving practical performance, improving force and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

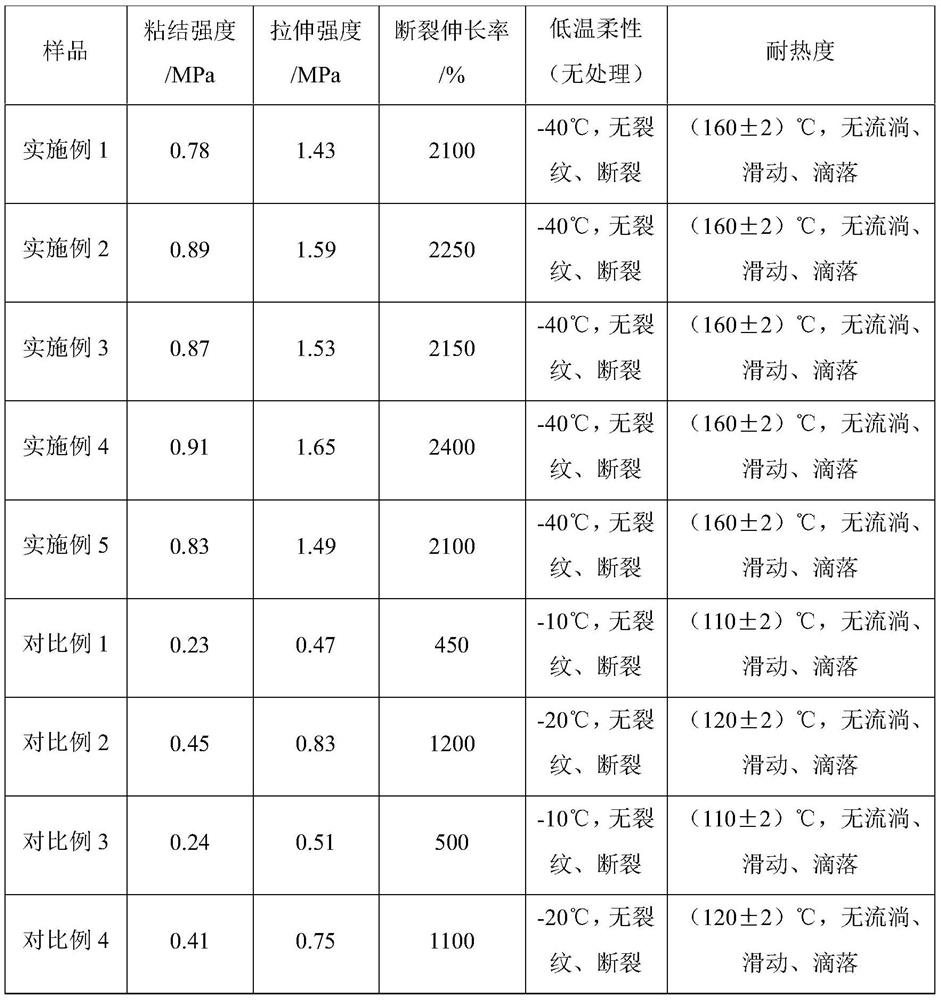

Examples

Embodiment 1

[0048] In this embodiment, the quick-setting rubber asphalt waterproof coating is sprayed, including A component and B component, and its specific preparation process is as follows:

[0049] Preparation of component A: In terms of mass percentage, 30% non-sulfurized styrene-butadiene latex, 69% anionic emulsified 70# asphalt, 0.5% methylene bis-naphthalene sulfonate, 0.1% sodium stearate, 0.2% colloidal sulfur , 0.2% sodium hydroxide, and stirred at room temperature for 1 hour to prepare component A, wherein the solid content of non-sulfurized styrene-butadiene latex was 70%, and the solid content of anionic emulsified 70# asphalt was 60%;

[0050] Preparation of component B: In terms of mass percentage, 0.5% nano-zinc oxide, 1% ammonium dithiocarbamate, 0.2% methylene bis-naphthalene sulfonate, 3% tetradecyltrimethylammonium bromide , 7.8% calcium bromide, stirred evenly, and then added to 87.5% water to disperse and dissolve to obtain component B.

Embodiment 2

[0052] In this embodiment, the quick-setting rubber asphalt waterproof coating is sprayed, including A component and B component, and its specific preparation process is as follows:

[0053] Preparation of component A: In terms of mass percentage, 17.5% non-sulfurized ethylene-propylene latex, 30% non-sulfurized styrene-butadiene latex, 50% anionic emulsified 90# asphalt, 1% sodium cellulose sulfonate, 0.5% potassium stearate , 0.8% colloidal sulfur, and 0.2% potassium hydroxide were mixed, and stirred at room temperature for 1 hour to obtain component A, wherein the solid content of non-sulfurized ethylene-propylene latex was 60%, and the solid content of non-sulfurized styrene-butadiene latex was 60%. The solid content of anionic emulsified 90# asphalt is 70%;

[0054] Preparation of component B: In terms of mass percentage, 1% nano-zinc oxide, 2% sodium dithiocarbamate, 0.5% sodium cellulose sulfonate, 2% cetyltrimethylammonium bromide, 7% bromine Calcium is mixed, stirred...

Embodiment 3

[0056] In this embodiment, the quick-setting rubber asphalt waterproof coating is sprayed, including A component and B component, and its specific preparation process is as follows:

[0057] Preparation of component A: In terms of mass percentage, 10% non-sulfurized nitrile latex, 30% non-sulfurized styrene-butadiene latex, 58% anionic emulsified 70# asphalt, 0.7% methylene bis-naphthalene sulfonate, 0.3% hard Sodium fatty acid, 0.5% colloidal sulfur, and 0.5% potassium hydroxide are mixed, and stirred at room temperature for 1 hour to obtain component A, wherein the solid content of non-sulfurized nitrile butadiene latex is 60%, and the solid content of non-sulfurized styrene-butadiene latex is 60%, the solid content of anionic emulsified 70# asphalt is 60%;

[0058] Preparation of component B: In terms of mass percentage, 0.7% nano-zinc oxide, 1.2% potassium dithiocarbamate, 0.1% methylene bis-naphthalene sulfonate, 2% tetradecyl imidazoline benzyl bromide Ammonium chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com