Acrylate polymer microsphere aggregate and preparation method thereof

An acrylate and polymer technology, applied in the field of acrylate polymer microsphere aggregate powder dressing, can solve the problems of low absorption capacity, high product cost, allergy to ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

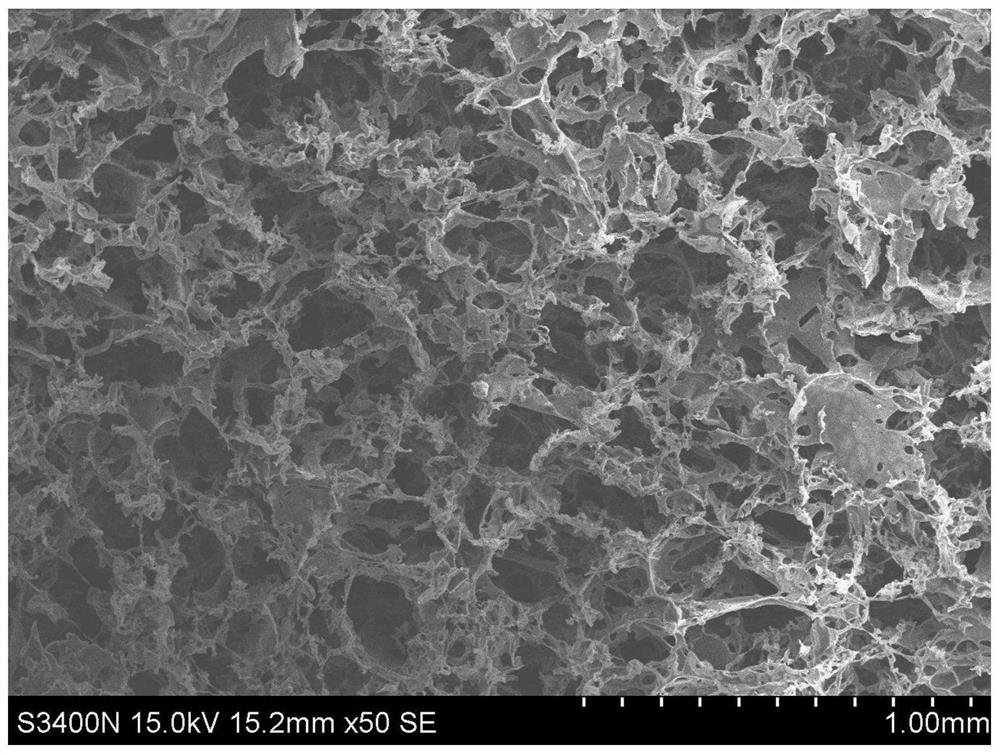

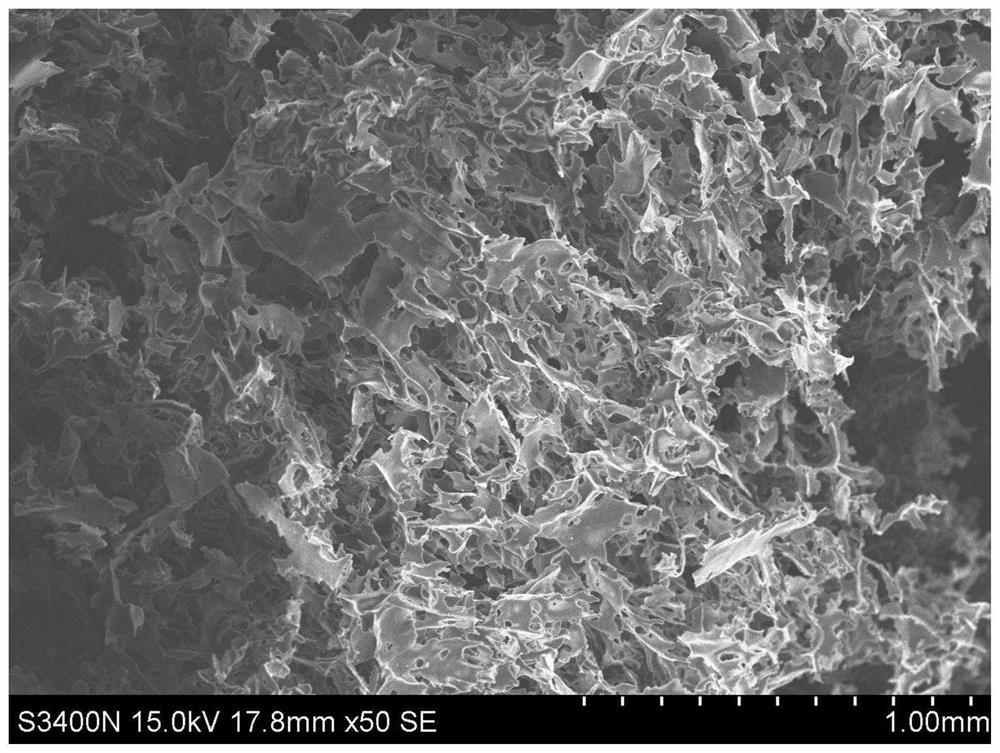

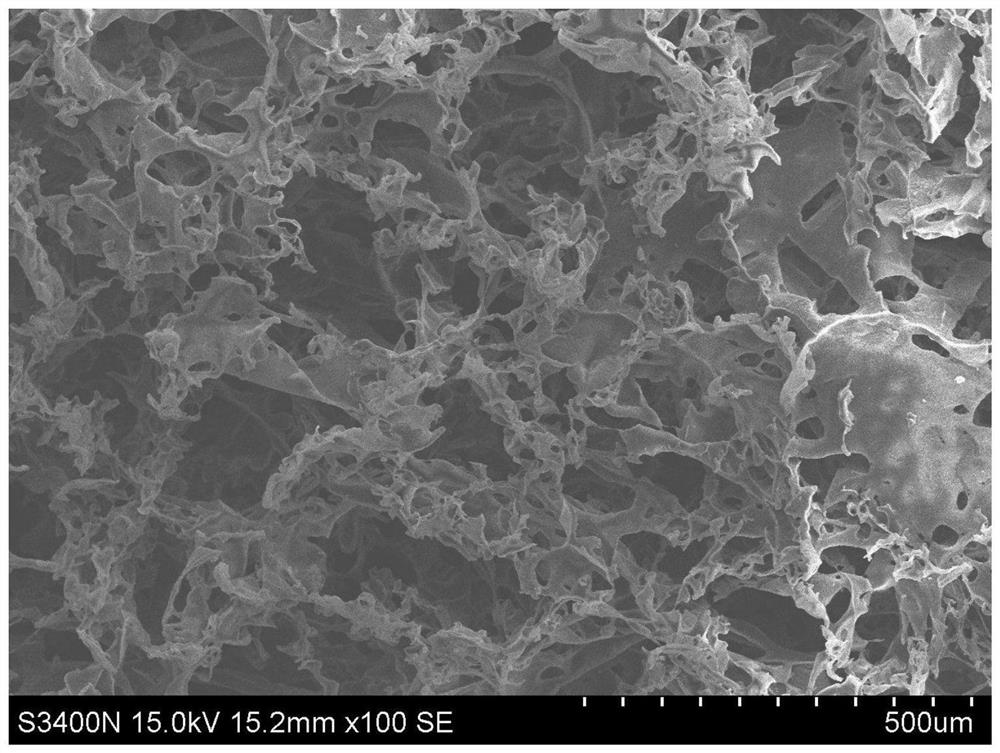

[0074] The present invention introduces new technical means in the preparation process of acrylate polymer microspheres so that the inside of the synthesized polymer microspheres has microporous channels, and new capillary channels are formed when the polymer microspheres aggregate during the drying process. The interaction of the pores makes the acrylate polymer powder fuse together quickly to form a polymer film with good water-permeable and air-permeable properties when encountering moisture-containing substances, thereby promoting the wet healing of wounds.

[0075] The present invention adopts core-shell emulsion polymerization to prepare microphase-separated polymer microspheres, first synthesizing a polymer core containing more hydrophilic monomers, and then adopting a continuous dropping process to prepare polymers containing more lipophilic monomers The shell controls the cross-linking density and ionization degree of the core and the shell, so that in the post-process...

Embodiment 1

[0137] A kind of acrylate polymer microsphere aggregate is prepared by the following steps:

[0138] (1) The preparation process of the core: Weigh 1.0 g of emulsifier sodium dodecyl sulfate (SDS) and 380 g of deionized water into a 500 mL four-neck flask, and then install a stirrer, nitrogen conduit, thermometer and condenser tube, The temperature of the water bath is maintained at 73°C, and the nitrogen gas is continuously introduced and the stirring is started. When the emulsifier is completely dissolved and the internal temperature reaches 70±1°C, add the pre-weighed monomer mixture, which contains 12g of hydroxyethyl methacrylate (HEMA), 8g hydroxypropyl methacrylate (HPMA), 1g methacrylic acid (MAA) and 0.4g diacetone acrylamide (DAAM), after the temperature stabilizes, add pre-dissolved potassium persulfate (KPS) The solution, which contained 0.1 g KPS and 20 g deionized water, was started. After about 5 minutes, the reactants showed blue light, and the monomers began ...

Embodiment 2

[0148] A kind of acrylate polymer microsphere aggregate is prepared by the following steps:

[0149] (1) The preparation process of the nucleus: Weigh 1.5g of emulsifier SDS and 380g of deionized water into a 500mL four-neck flask, and then install a stirrer, nitrogen conduit, thermometer and condenser. The temperature of the water bath is maintained at 73°C, and the Introduce nitrogen and start stirring. When the emulsifier is completely dissolved and the internal temperature reaches 70±1°C, add the pre-weighed monomer mixture, which contains 16g HEMA, 4g HPMA, 1.5g MAA and 0.2g DAAM. After stabilization, add the pre-dissolved KPS solution, which contains 0.15g KPS and 20g deionized water, and start the timer. After about 5 minutes, the reactants showed blue light, and the monomers began to polymerize to form polymer particles. After about 6 hours, the nucleus preparation reaction was completed.

[0150] (2) Weigh 200g of nuclear emulsion and 190g of deionized water into a 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com