A kind of cellulose graft copolymer and its preparation method and application in injectable hydrogel

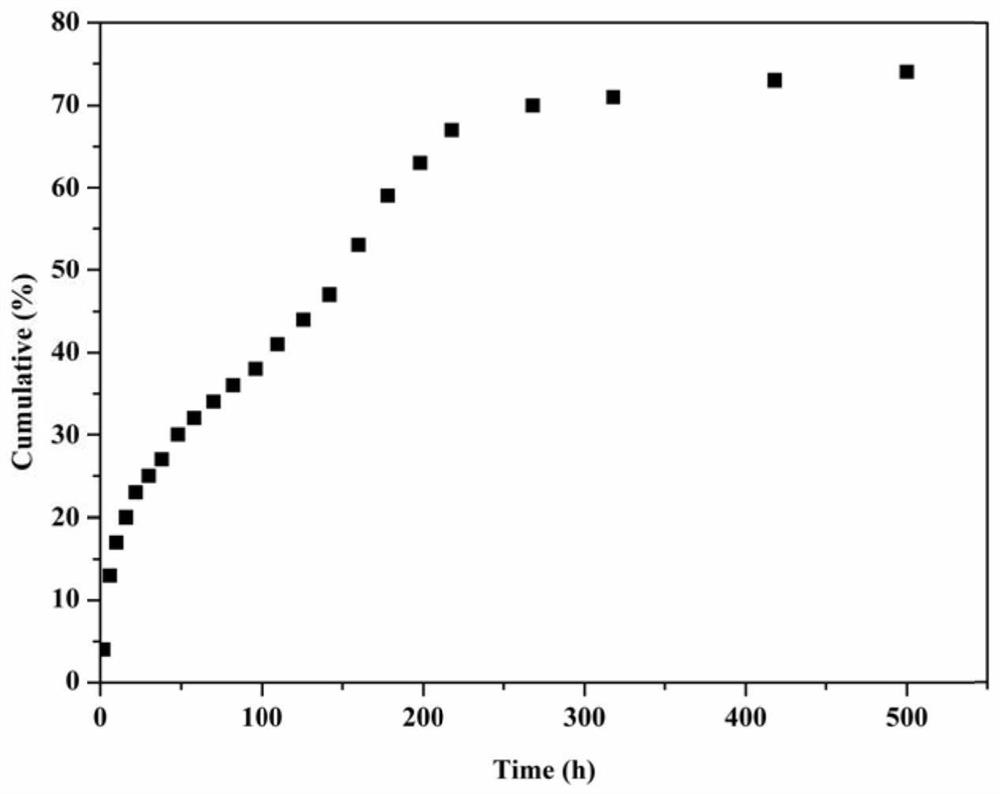

A technology of cellulose graft and copolymer, applied in the field of cellulose graft copolymer and its preparation, to achieve the effects of strong operability, good slow-release effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

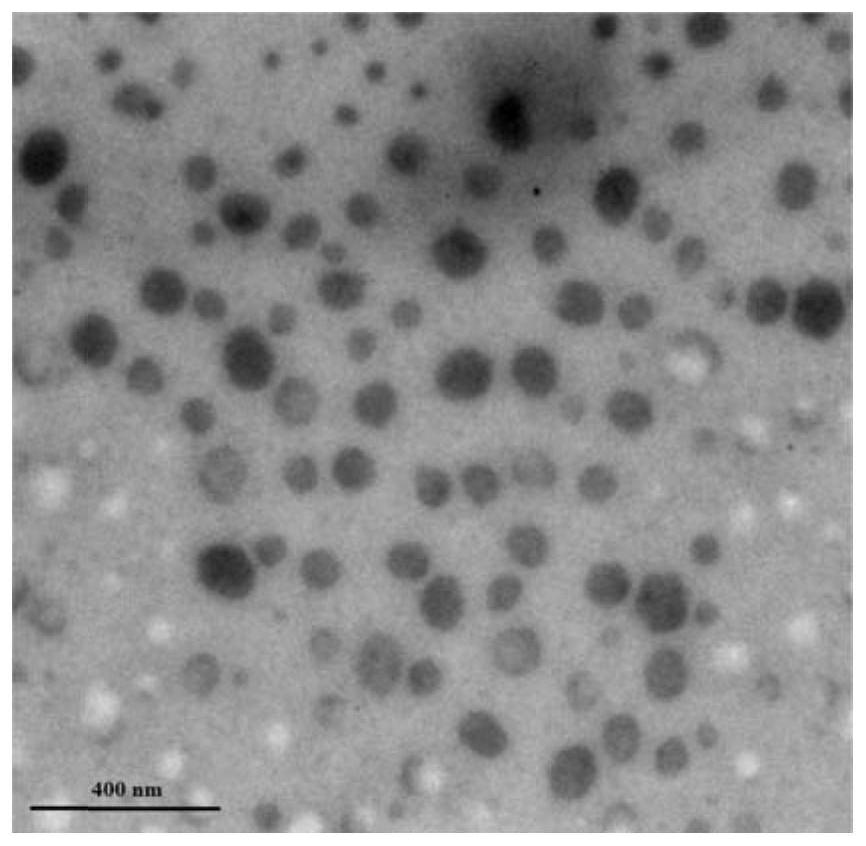

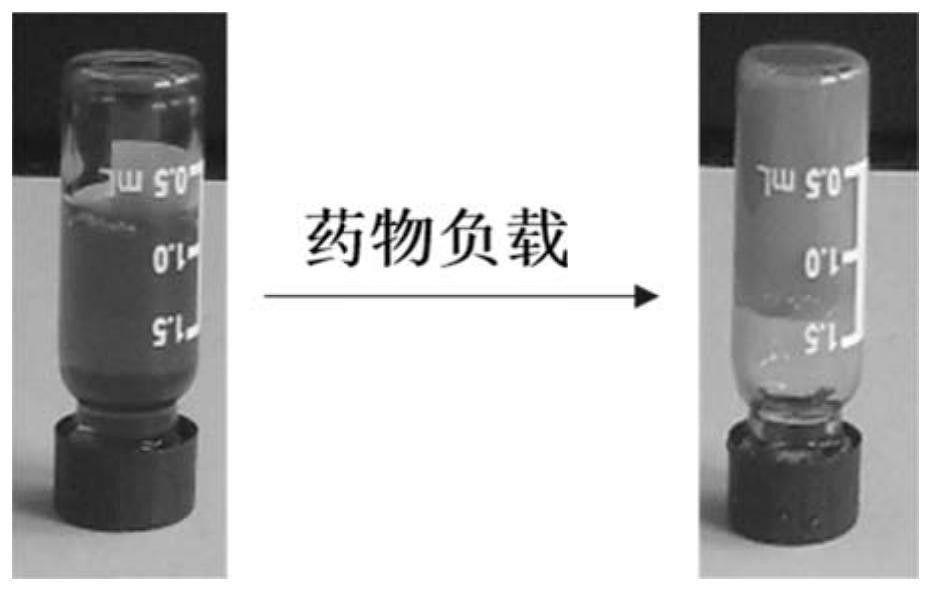

Image

Examples

Embodiment 1

[0037] The preparation method of cellulose-based injectable hydrogel is as follows:

[0038] (1) Dissolution of cellulose: LiCl / DMAc system was used to dissolve cellulose. First, 6 g of cellulose and 18 g of LiCl were dried in a vacuum oven at 100 °C for 24 h, and then the dried cellulose was added to 176 g of N,N-di In methylacetamide (DMAc), the mixture was then activated at 160°C for 2 hours at high temperature, then LiCl was added and the temperature was lowered to 100°C, kept for several hours, then lowered to room temperature and stirred until completely dissolved.

[0039] (2) Formation of cellulose macromolecular initiator: get 54g of the above-mentioned solution in the Xinweier reaction flask that rotor is housed, then add 7.5ml 2-bromoisobutyryl bromide (BIBB) dropwise with constant pressure separatory funnel in Reaction at room temperature for 12h. After the reaction was completed, the mixture was poured into 100 ml of deionized water, followed by centrifugal washi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com