Process method capable of improving breaking limit of permanent magnetic ferrite magnetic shoe device

A technology of permanent magnet ferrite and process method, applied in the field of permanent magnet ferrite, can solve the problem that the particle size state of wet ball abrasive powder cannot be completely reflected, and achieve the effect of improving the flexural limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

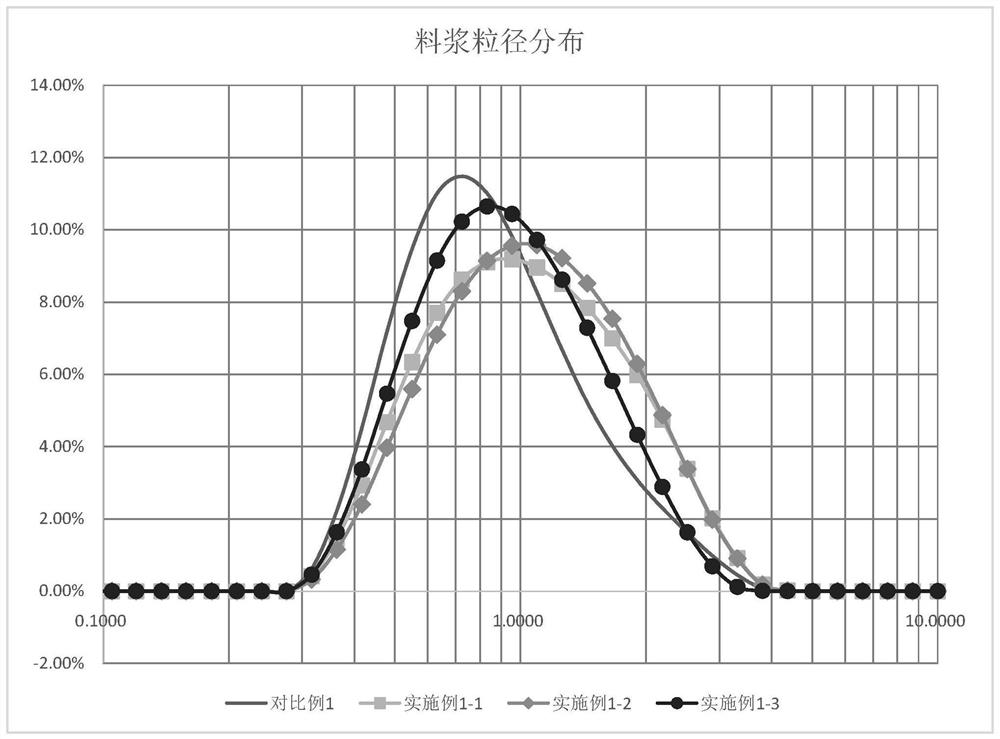

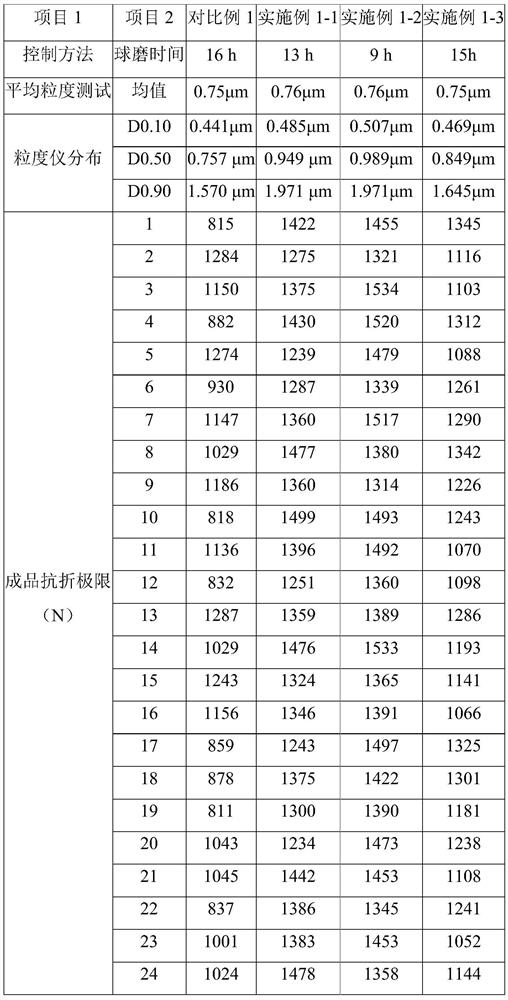

[0044] Control slurry particle size

[0045] The raw material formula used in the preparation of the permanent ferrite magnetic tile device in this embodiment is: permanent magnet strontium ferrite pre-fired powder 600-800kg, waste magnetic steel powder 500-700kg, grinding powder 100-300kg, calcium carbonate 12-16kg, silicon oxide 1.5-4.5kg, boric acid 1.5-4.5kg, wherein, the average particle diameter of raw materials is 3-8 microns.

[0046] The permanent magnet ferrite magnetic tile device of this embodiment is prepared by using the above raw materials mixed uniformly and then undergoing ball milling, pressing, sintering and grinding in sequence. Wherein, in this embodiment, only by improving the ball milling time, the particle size distribution after ball milling can satisfy D0.10: 0.4-0.6 μm, D0.50: 0.8-1.0 μm, D0.90: 1.9-2.0 μm.

[0047] Specifically, a process method for improving the flexural limit of a permanent ferrite magnetic tile device, the steps are:

[0048] (...

Embodiment 2

[0062] Improved Green Density Consistency

[0063] This embodiment is a process method for improving the flexural limit of permanent ferrite magnetic tile devices, which is basically the same as that of Embodiment 1-1, the difference is that in this embodiment, the single-cavity grouting flow rate is increased during the pressing process , Grouting pressure, and grouting time to improve the consistency of green body density.

[0064] Specifically, the suppression control process is as follows:

[0065] Control method: grouting pressure, grouting time, grouting flow rate

[0066] Grouting pressure range: 2-4MPa before improvement (comparative example 2), 6-12MPa after improvement (this embodiment)

[0067] Grouting time range: 1-4s before improvement (comparative example 2), 7-15s after improvement (this embodiment)

[0068] Single-cavity grouting flow rate range: 50-80mm / s before improvement (comparative example 2), 15-40mm / s after improvement (this embodiment)

Embodiment 3

[0075] surface polishing

[0076] This embodiment is a process for improving the flexural limit of permanent ferrite magnetic tile devices, which is basically the same as that of embodiment 2-1. number.

[0077] Concrete, present embodiment grinding wheel is as follows:

[0078] Control method: fine grinding wheel mesh

[0079] Grinding wheel mesh range: 80-120 mesh before improvement (comparative example 3), 150-400 mesh after improvement (this embodiment)

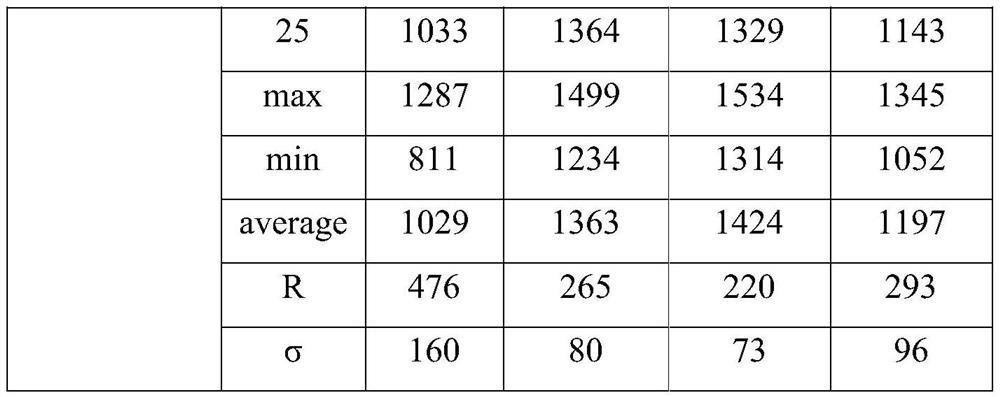

[0080] As shown in Table 3, 25 finished magnetic tiles from Comparative Example 3, Example 3-1, Example 3-2, and Example 3-3 were taken respectively, and their flexural limits were tested.

[0081] Table 3 Comparative Example 3 and Example 3-1, Example 3-2, and Example 3-3 The flexural limit of the finished magnetic tile

[0082]

[0083]

[0084] As can be seen from Table 3, the flexural limit of the finished product of Example 3-1 is 16.87% higher than that of Comparative Example 3, the flexural limit of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com