Modified cuprous ferrite catalystrich in oxygen vacancies as well as preparation method and application thereof

A cuprous ferrite, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of reducing the dosage and improving the degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of modified cuprous ferrite catalyst, comprising the following steps:

[0029] mixing the chitosan solution and the iron-copper metal salt solution, dropping the resulting mixed solution into alkali, and carrying out a precipitation reaction to obtain an iron-copper precipitation mixed solution coated with chitosan;

[0030] The chitosan-coated iron-copper precipitation mixed solution is subjected to hydrothermal reaction and dried to obtain a modified cuprous ferrite catalyst.

[0031] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0032] The invention mixes the chitosan solution and the iron-copper metal salt solution, drops the obtained mixed solution into the alkali, carries out the precipitation reaction, and obtains the iron-copper precipitation mixed solution coated with the chitosan. In the p...

Embodiment 1

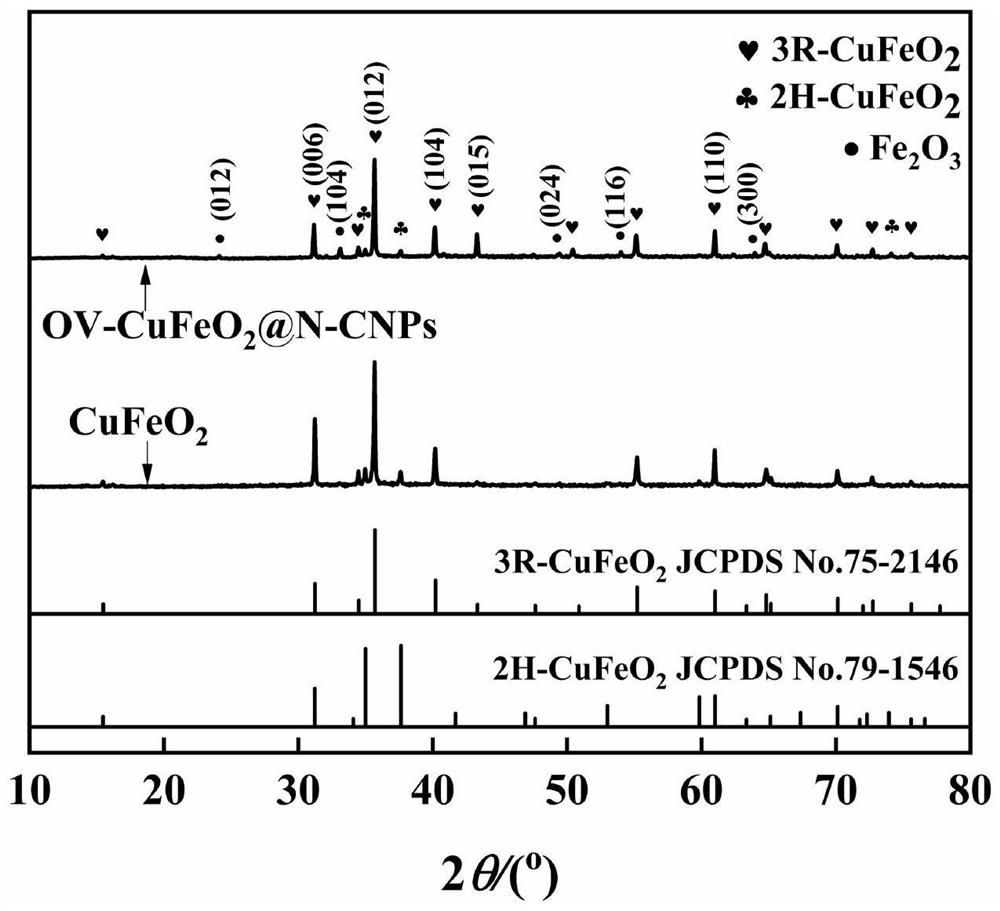

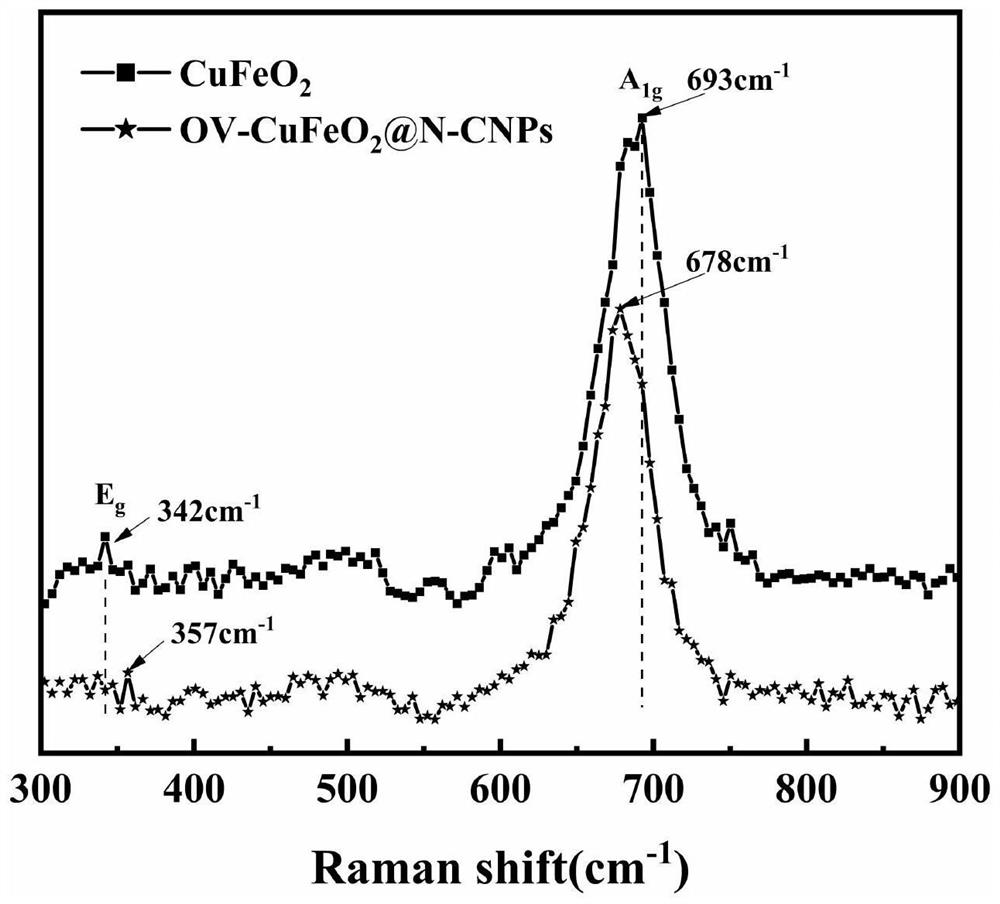

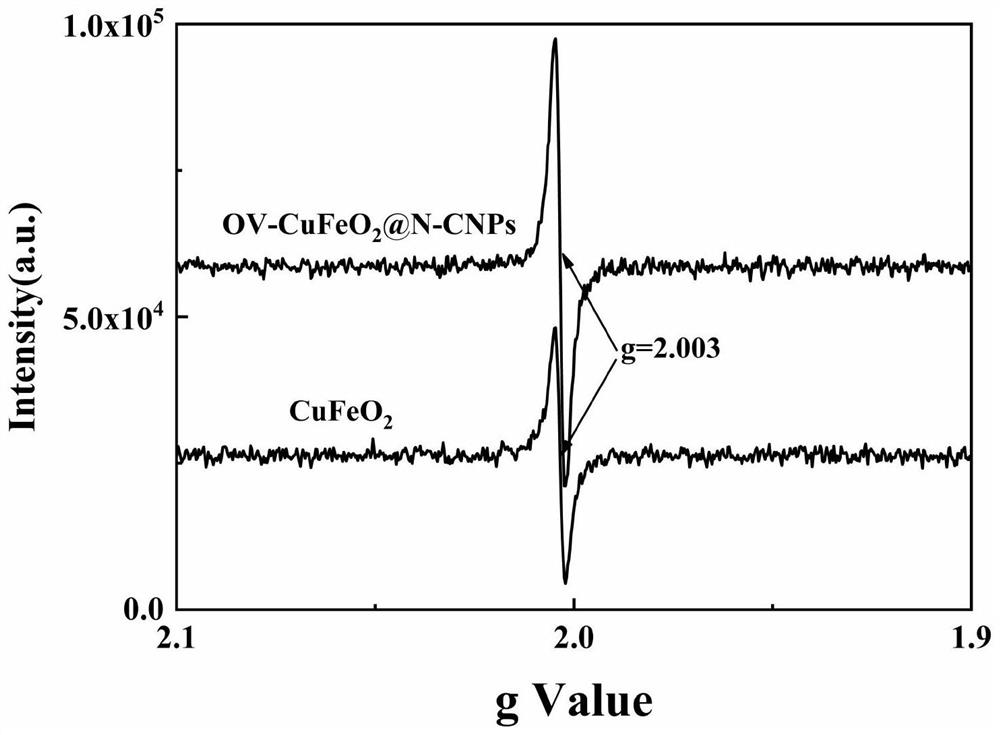

[0045] 200mg chitosan was dissolved in 20mL 2% glacial acetic acid solution, and left to stand overnight to obtain chitosan solution; weigh 5mmol Cu(NO 3 ) 2 ·3H 2 O and 5 mmol FeSO 4 ·7H 2 O was dissolved in 10mL ultrapure water, and the obtained iron-copper metal salt solution was slowly added to the chitosan solution, stirred to make it evenly mixed, and then the obtained mixed solution was dropped into 30mL1.67mol / L NaOH aqueous solution drop by drop. , carry out the precipitation reaction at room temperature for 60 minutes, the obtained iron-copper precipitation mixed solution coated with chitosan is sonicated for 10 minutes, and then put into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and carry out hydrothermal reaction at 180 ° C for 12 hours. The obtained product was centrifugally washed until the surface of the product was neutral, and dried in vacuum at 60°C for 12 hours to obtain a modified cuprous ferrite catalyst, which was denoted ...

Embodiment 2

[0047] The difference between this embodiment and Example 1 is only that the amount of chitosan added is 100 mg, and the prepared catalyst is denoted as OV-CuFeO 2 @N-CNPs-100; In the prepared modified cuprous ferrite catalyst, the loading amount of nitrogen-doped carbon nanoparticles on the cuprous ferrite is 9.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com