Stereoscopically formed vamp and processing technology

A technology of three-dimensional molding and processing technology, which is applied in the direction of shoe uppers, footwear, footwear, etc., and can solve the problems of unfinished, backing film deviation of three-dimensional fine lines, etc., to achieve strong three-dimensional effect, softness and uniformity, three-dimensional effect And the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

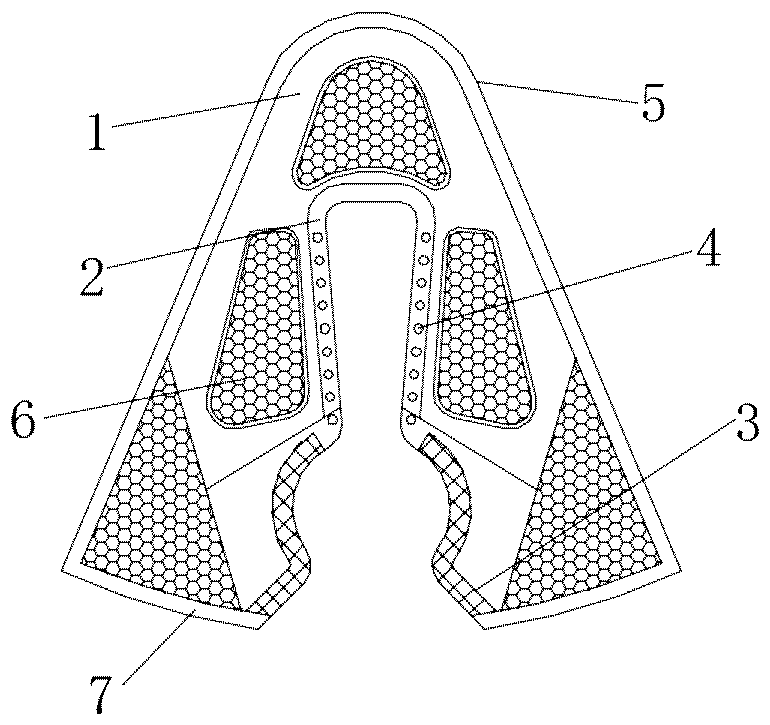

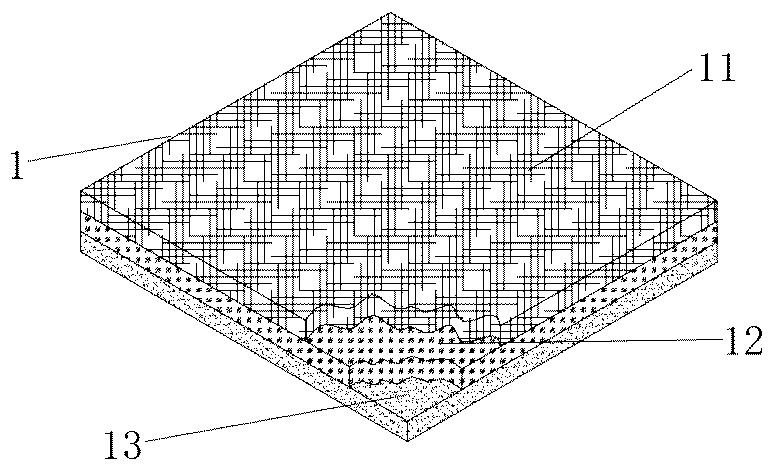

[0030] A three-dimensional molded vamp, comprising a vamp main body 1, a front lining 2, a rear panel 3, eyelets 4, a sole edge 5, a decorative sheet 6 and a rear patch 7, the toe cap of the vamp main body 1, the shoe body and The heel portion is provided with a decorative sheet 6, and the center is provided with a front lining 2, and the edge of the front lining 2 is provided with a number of eyelets 4 correspondingly. The outer edge is provided with a rear patch 7, and the bottom edge of the upper body 1 is provided with a sole edge 5. The upper body 1 includes a TPU polyurethane film 11, a TPU closed-cell polyurethane foam layer 12, and a PU polyurethane layer 13. TPU polyurethane The adhesive film 11, the TPU closed-cell polyurethane foam layer 12 and the PU polyurethane layer 13 are calendered and compounded sequentially from top to bottom.

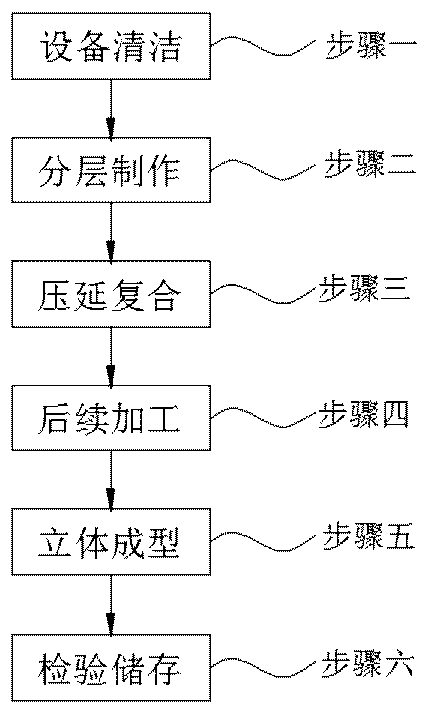

[0031] A processing technology for three-dimensionally formed shoe uppers, comprising the following steps: Step 1, equipment cleani...

Embodiment 2

[0043]A three-dimensional molded vamp, comprising a vamp main body 1, a front lining 2, a rear panel 3, eyelets 4, a sole edge 5, a decorative sheet 6 and a rear patch 7, the toe cap of the vamp main body 1, the shoe body and The heel portion is provided with a decorative sheet 6, and the center is provided with a front lining 2, and the edge of the front lining 2 is provided with a number of eyelets 4 correspondingly. The outer edge is provided with a rear patch 7, and the bottom edge of the upper body 1 is provided with a sole edge 5. The upper body 1 includes a TPU polyurethane film 11, a TPU closed-cell polyurethane foam layer 12, and a PU polyurethane layer 13. TPU polyurethane The adhesive film 11, the TPU closed-cell polyurethane foam layer 12 and the PU polyurethane layer 13 are calendered and compounded sequentially from top to bottom.

[0044] A processing technology for three-dimensionally formed shoe uppers, comprising the following steps: Step 1, equipment cleanin...

Embodiment 3

[0056] A three-dimensional molded vamp, comprising a vamp main body 1, a front lining 2, a rear panel 3, eyelets 4, a sole edge 5, a decorative sheet 6 and a rear patch 7, the toe cap of the vamp main body 1, the shoe body and The heel portion is provided with a decorative sheet 6, and the center is provided with a front lining 2, and the edge of the front lining 2 is provided with a number of eyelets 4 correspondingly. The outer edge is provided with a rear patch 7, and the bottom edge of the upper body 1 is provided with a sole edge 5. The upper body 1 includes a TPU polyurethane film 11, a TPU closed-cell polyurethane foam layer 12, and a PU polyurethane layer 13. TPU polyurethane The adhesive film 11, the TPU closed-cell polyurethane foam layer 12 and the PU polyurethane layer 13 are calendered and compounded sequentially from top to bottom.

[0057] A processing technology for three-dimensionally formed shoe uppers, comprising the following steps: Step 1, equipment cleani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com