Linear cavity all-fiber laser oscillator for wavelength locking 97Xnm waveband pumping

A laser oscillator, linear cavity technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of high light-light conversion efficiency, obvious local heat load, unstable fiber mode, etc., and achieve absorption coefficient. Low, improve the nonlinear effect threshold, improve the effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] In order to verify the effectiveness of the scheme of the present invention, the following experiments were carried out.

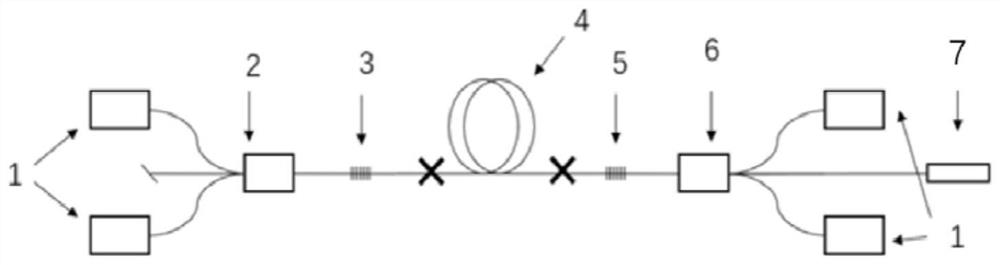

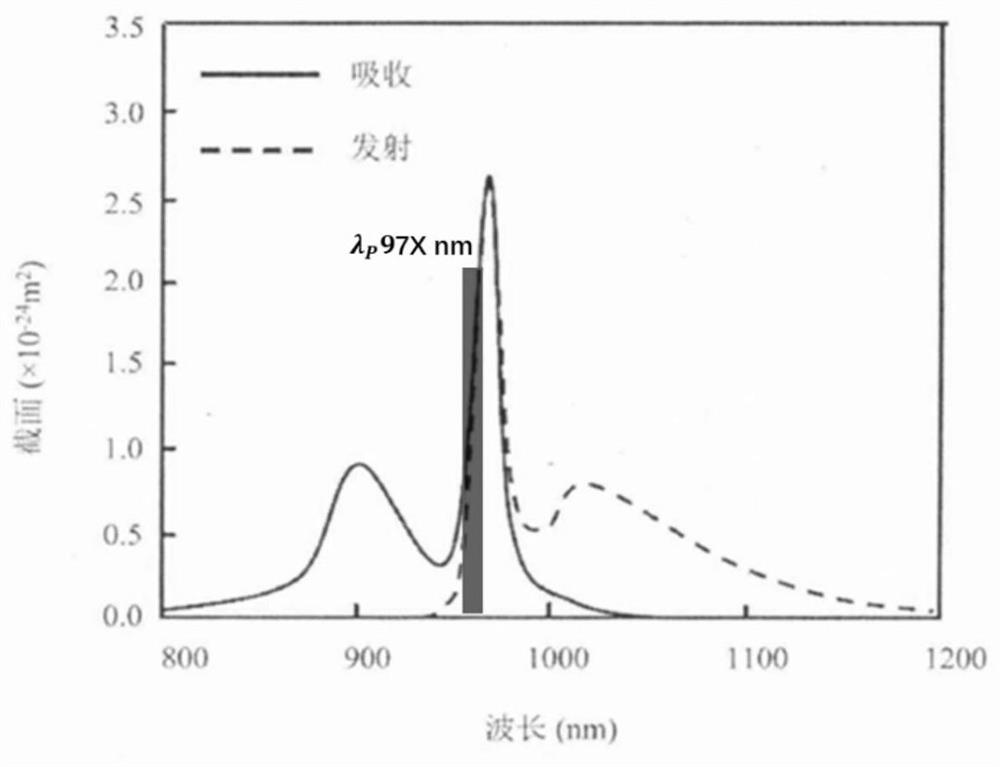

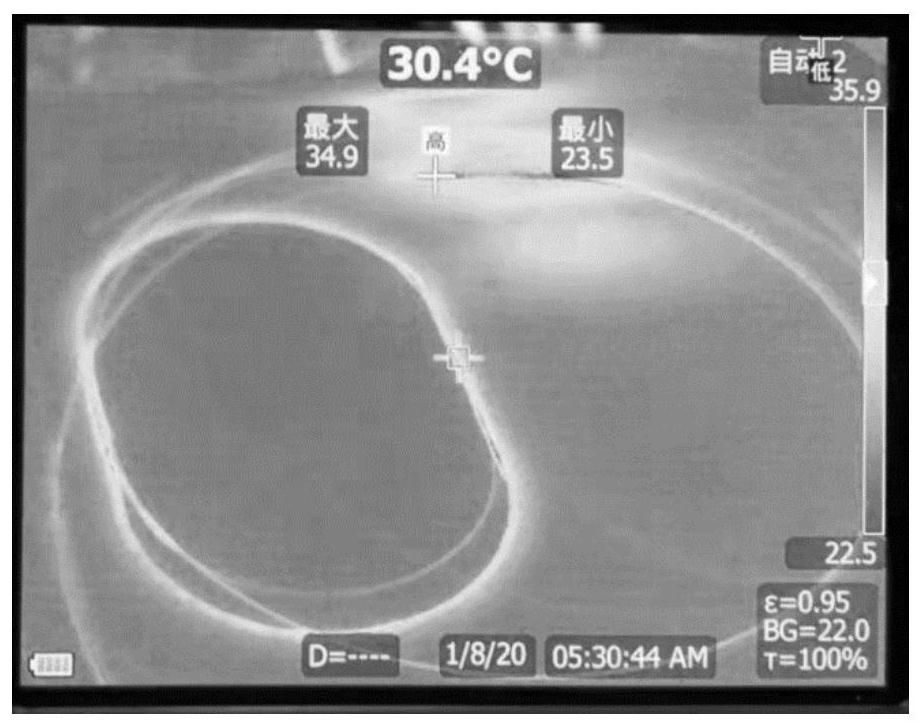

[0022] The backward fiber grating 5, the gain fiber 4, and the forward fiber grating 3 are sequentially connected through signal transmission fibers to form a fiber laser resonator. The central wavelength of the fiber grating is 1080 nm, the reflectivity of the high-reflection and low-reflection gratings is ~99% and ~10%, respectively, and the structural parameters of the gain fiber are 20 / 400 μm. The pump light is coupled and injected into the resonator using a beam combiner. The laser output from the resonator is output through the end cap (QBH). The thermal imager measures the temperature of the resonant cavity, the power meter measures the output power of the laser, and the spectrometer measures the spectrum of the output light by measuring scattered light. The pumping wavelengths studied in the experiment are 976 nm and 97Xnm, their absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com