A serpentine microchannel heat sink for laser strip crystals

A micro-channel and strip-type technology, applied in the direction of lasers, laser components, laser components, etc., to achieve the effects of weakening temperature gradients, high heat carrying capacity, and small flow differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments disclosed in the present invention will be described in further detail below with reference to the accompanying drawings.

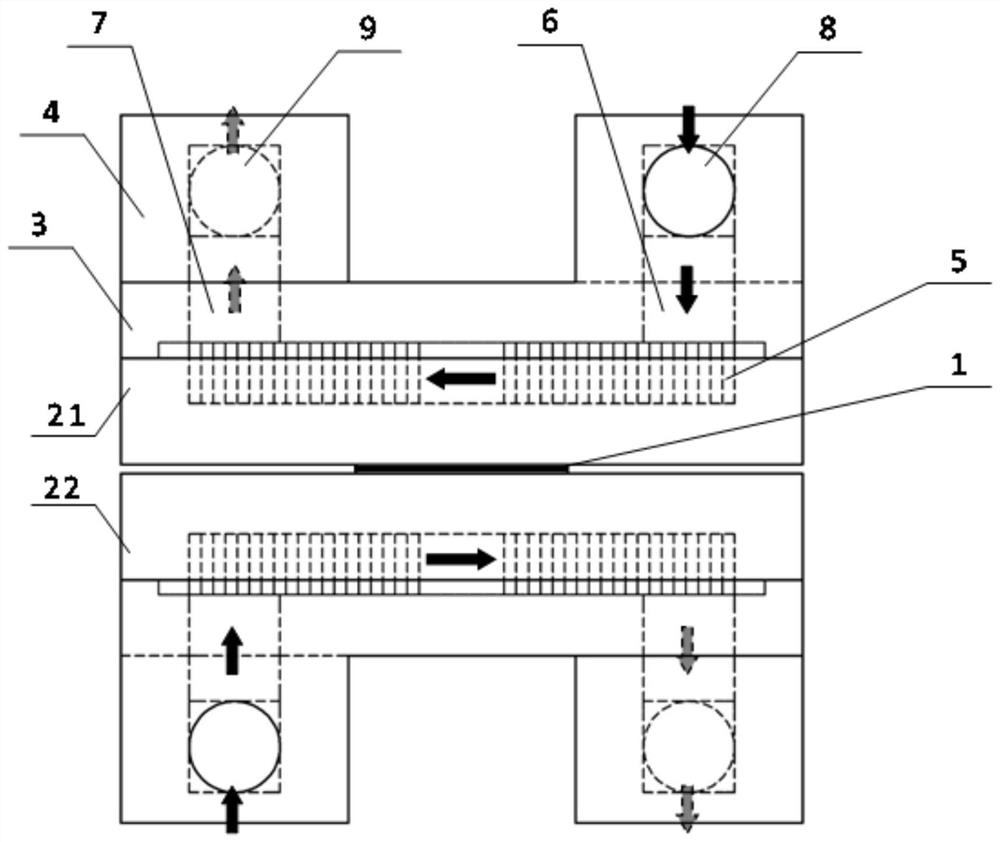

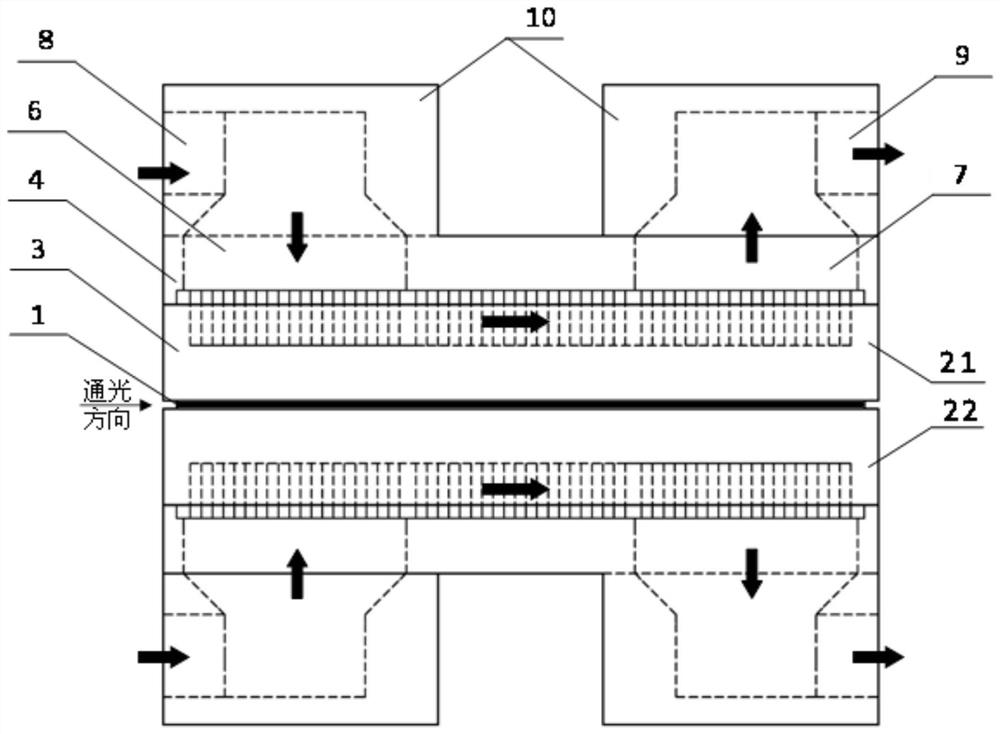

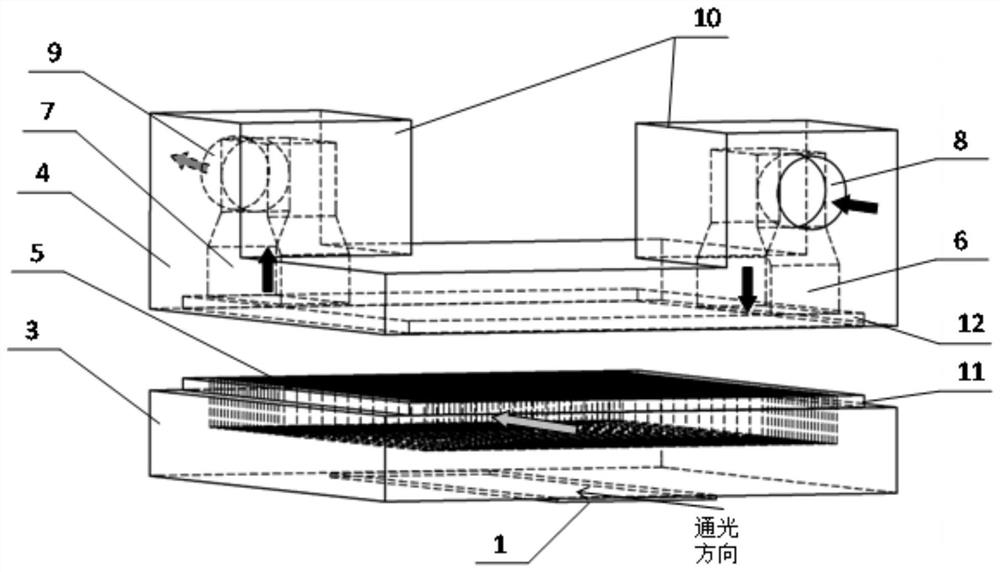

[0041]One of the core ideas of the present invention is to provide a serpentine microchannel radiator for a laser strip crystal, including a laser strip crystal and two sets of upper and lower serpentine microchannel radiators with the same structure. The upper and lower sides of the strip-type crystal are respectively combined with the bottom heat-absorbing surfaces of the two groups of serpentine microchannel radiators; the serpentine microchannel radiator is a two-layer structure, including a microchannel layer and a cover plate layer; Road snake-type micro-channel structure; the cover layer is provided with an inlet header and an outlet header, which respectively provide the inlet and outlet of the working medium for the microcha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com