Dynamic bending adjusting device and dynamic stable micron focusing system

An adjustment device and dynamic technology, applied in the application of diffraction/refraction/reflection for processing, nuclear engineering, radiation/particle processing, etc., can solve the problems of large spatial distance of focusing optical system, insufficient to meet application requirements, etc., and achieve optimal structure. , the effect of improving stability, high stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

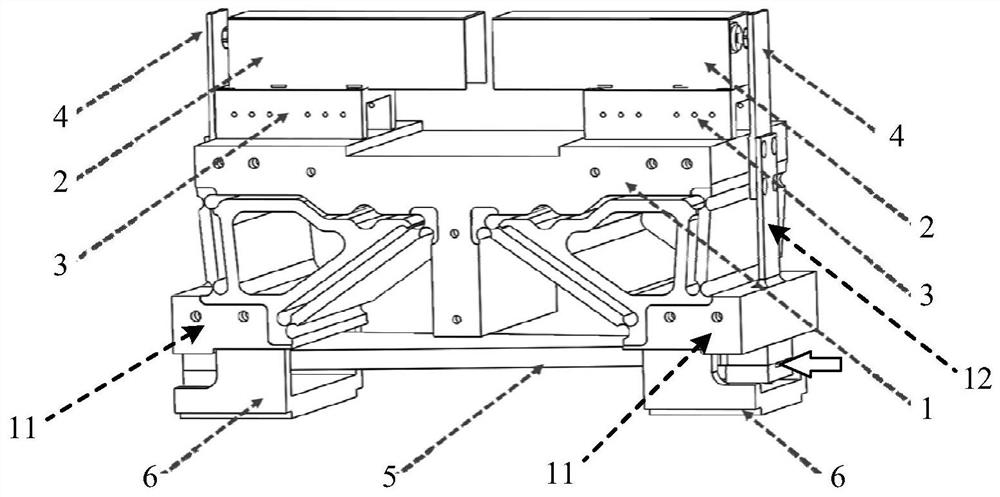

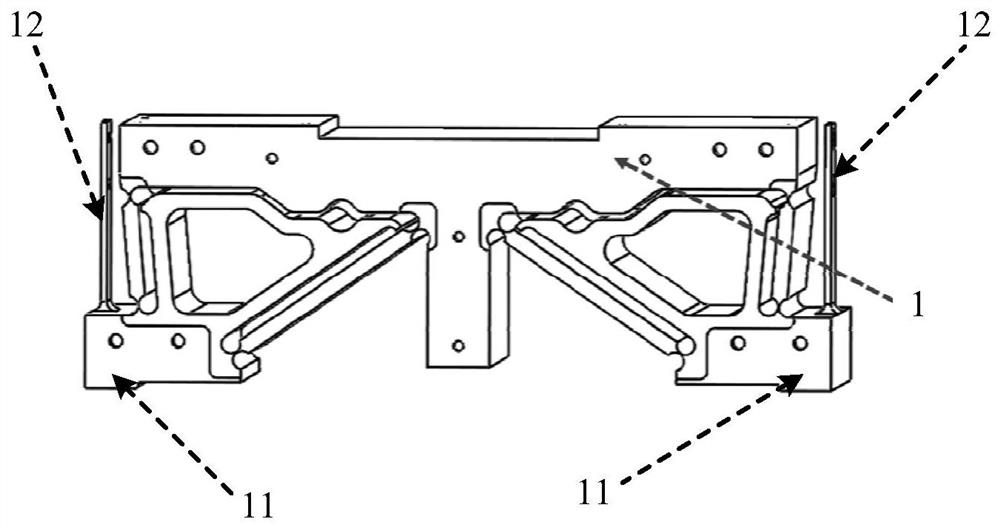

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a dynamic bending adjustment device, which is basically an axisymmetric structure, including a compliance mechanism 1, two micro-displacement drivers 2, two support frames 3, two connectors 4, and two reflectors. Mirror holder 6 and grazing incidence mirror 5. Wherein the bottom of the compliance mechanism 1 is provided with two mounts 11, such as figure 2 As shown, they are respectively located on both sides of the bottom of the compliance mechanism 1. Each mounting base 11 is provided with an adjustment plate 12, and the adjustment plate 12 extends vertically upward from the upper surface of the installation base 11; On the opposite sides of the top of the mechanism 1, the two connecting pieces 4 are respectively connected to the free ends of the two adjustment plates 12 by screws, and extend in a direction vertical and away from the mounting base 11, and the two micro-displacement drivers 2...

Embodiment 2

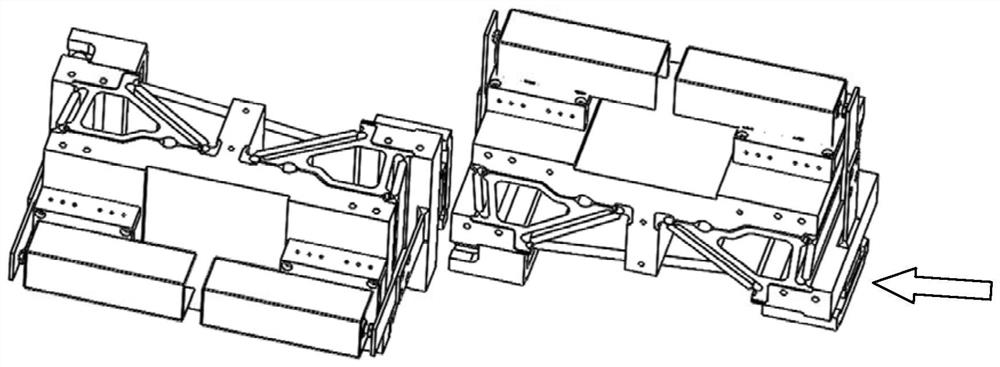

[0047] This embodiment provides a dynamic and stable micro-focusing system, which includes a plurality of dynamic bending adjustment devices described in Embodiment 1, and a plurality of dynamic bending adjustment devices are combined to form a Kirkpatrick-Baez type optical focusing system, Montel Type optical focusing system or Wolter type focusing optical system.

[0048] Such as image 3 As shown, it is a Kirkpatrick-Baez focusing optical system composed of two dynamic bending adjustment devices, where the two dynamic bending adjustment devices are arranged in front and back and are orthogonal to each other. During use, the grazing incident light along the direction of the arrow is reflected and focused into a line by the grazing incidence mirror of the first dynamic bending adjustment device, and then is second-time by the grazing incidence mirror of the second dynamic bending adjustment device The reflection is focused to a point, achieving two-dimensional focusing.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com