Continuous beam bridge suitable for tunnel to pass through huge karst cave and construction technical method thereof

A karst cave and giant technology, applied in bridges, bridge construction, infrastructure engineering, etc., can solve problems such as hidden dangers in tunnel structure and operation safety, karst pipeline blockage, etc., and achieve the effects of easy promotion, reduced construction volume, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

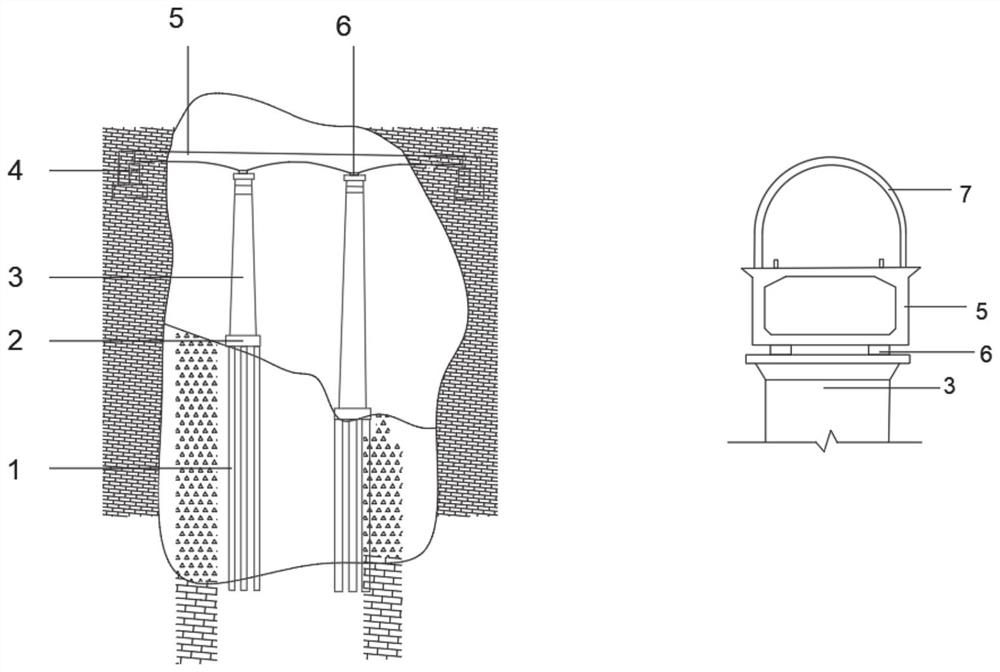

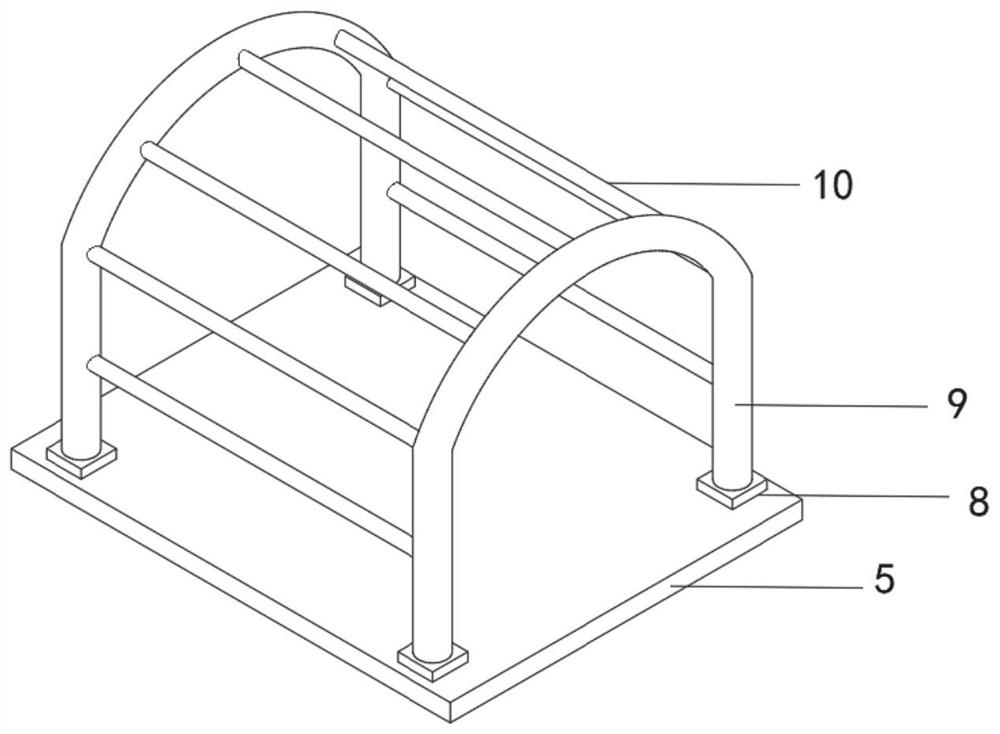

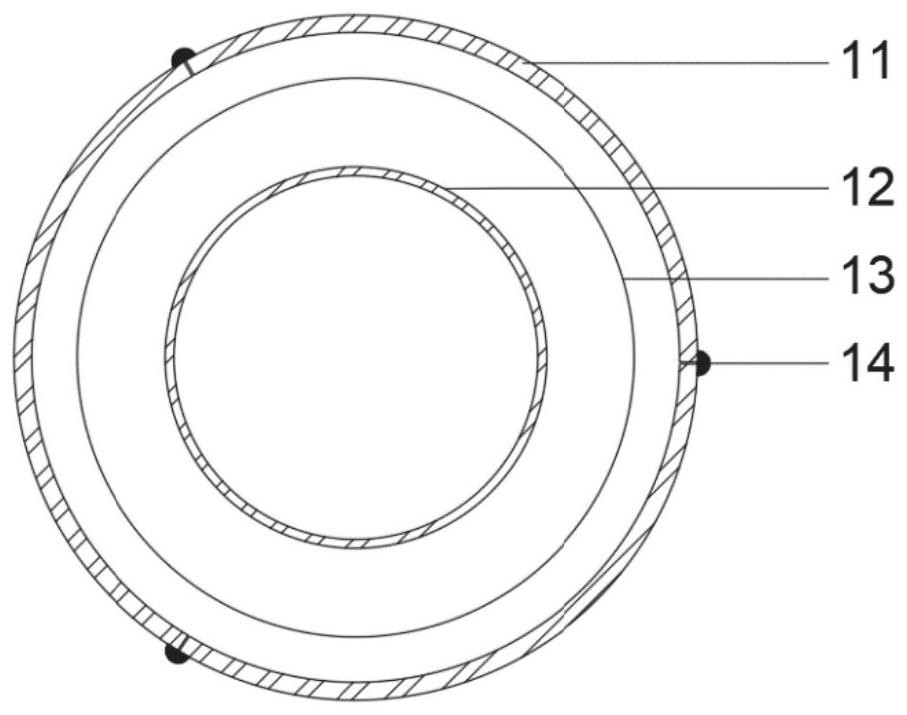

[0042] The invention proposes a continuous beam bridge construction technology suitable for tunnels passing through giant karst caves, the key points of which are the continuous beam bridge structure, micro-steel pipe pile combined pier foundation, protective scaffolding and construction method.

[0043] (1) Structural composition of continuous girder bridge

[0044] The superstructure of the continuous girder bridge includes: bearings (basin rubber bearings), beam slabs (single-box single-chamber beam slabs), bridge deck structure (bridge deck pavement, waterproof layer, expansion joints, etc.), bridge deck accessories Structure (anti-collision guardrail, isolation pier, sound insulation screen, etc.); substructure includes: pier (light pier), bridge abutment (light abutment), foundation (steel pipe pile foundation), cap (high pile cap).

[0045] (2) Pre-construction survey and fixed-point bridge setting

[0046] The pre-construction survey mainly includes: surveying and map...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com