Low-chlorine wet strength agent and preparation method thereof, and application in living paper

A wet strength agent, life-saving technology, applied in the direction of special paper, strengthening agent addition, textiles and papermaking, etc., to achieve the effect of reducing the cost of technological transformation, reducing the content of organic chlorine, and meeting strict standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

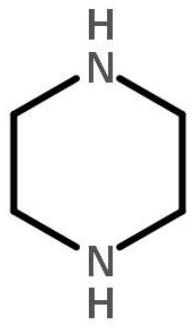

Method used

Image

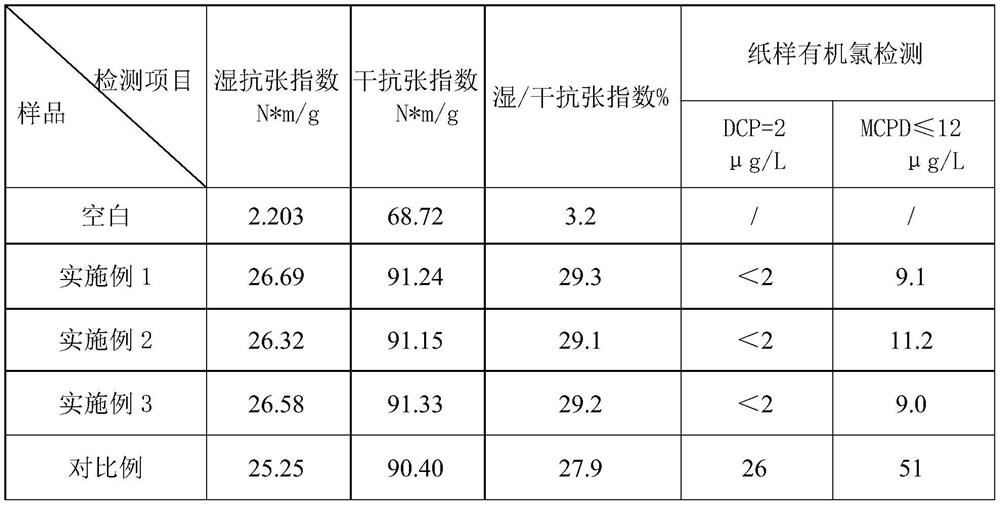

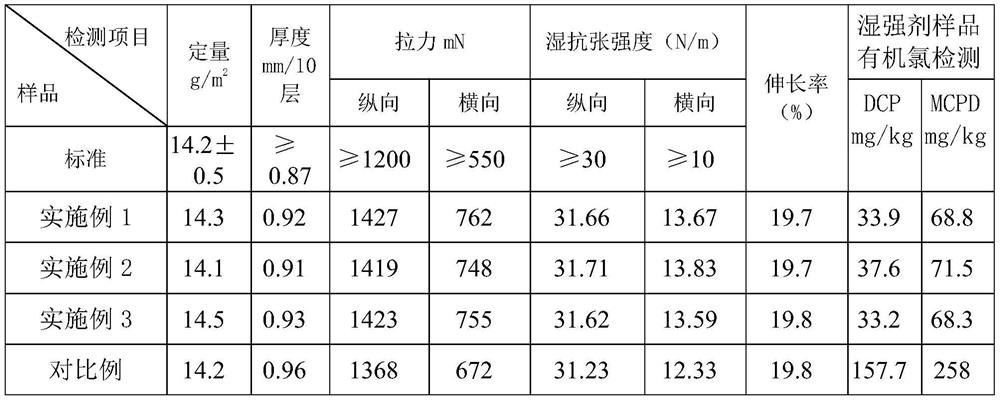

Examples

Embodiment 1

[0026] Preparation of low chlorine wet strength agent:

[0027] Mix 102.3 grams (0.7mol) of adipic acid and 68.9 grams (0.8mol) of diethylenediamine, raise the temperature to 135°C, keep warm for 30 minutes, then raise the temperature to 175°C, keep warm for 4 hours, then cool down, then add 220g of deionized water to obtain a polyamide polyamine prepolymer aqueous solution. Add 1000 grams of deionized water to the above polyamide prepolymer aqueous solution, stir evenly, slowly add 92.52 grams (1 mol) of epichlorohydrin dropwise at room temperature, stir for 10 minutes, then raise the temperature to 50°C, keep the temperature for 2 hours, and then heat up to 60°C, keep warm for 3.5 hours, add 15 grams of sulfuric acid as a terminator, and add 850 grams of later water, keep warm at 40°C for 30 minutes, cool down after the reaction, the product obtained is a low chlorine wet strength agent, and the shear viscosity is 35 centipoise .

Embodiment 2

[0029] Preparation of low chlorine wet strength agent:

[0030] Mix 102.3 grams (0.7mol) of adipic acid and 60.3 grams (0.7mol) of diethylenediamine, heat up to 135°C, keep warm for 30 minutes, then heat up to 175°C, keep warm for 4 hours, then cool down, then add 200g of deionized water to obtain a polyamide polyamine prepolymer aqueous solution. Add 950 grams of deionized water to the above polyamide prepolymer aqueous solution, stir evenly, slowly add 92.52 grams (1 mol) of epichlorohydrin at room temperature, stir for 10 minutes, then raise the temperature to 50°C, keep the temperature for 2 hours, and then heat up to 60°C, keep warm for 3.5 hours, add 14 grams of sulfuric acid as a terminator, and add 830 grams of late water, keep warm at 40°C for 30 minutes, cool down after the reaction, the product obtained is a low chlorine wet strength agent, and the shear viscosity is 36 centipoise .

Embodiment 3

[0032] Preparation of low chlorine wet strength agent:

[0033] Mix 102.3 grams (0.7mol) of adipic acid and 77.5 grams (0.9mol) of diethylenediamine, heat up to 138°C, keep warm for 30 minutes, then heat up to 177°C, keep warm for 4 hours, then cool down, and then add 240g of deionized water to obtain a polyamide polyamine prepolymer aqueous solution. Add 1020 grams of deionized water to the above polyamide prepolymer aqueous solution, stir evenly, slowly add 92.52 grams (1 mol) of epichlorohydrin dropwise at room temperature, stir for 10 minutes, then raise the temperature to 50°C, keep the temperature for 2 hours, and then heat up to 60°C, keep warm for 3.5 hours, add 14 grams of sulfuric acid as a terminator, and add 880 grams of later water, keep warm at 40°C for 30 minutes, cool down after the reaction, the product obtained is a low chlorine wet strength agent, and the shear viscosity is 35 centipoise .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com