Modified coating water repellent agent and preparation method thereof

A water-repellent agent and coating technology, which is applied in the direction of water-repellent agent addition, coating, paper coating, etc., can solve the problems of product storage and adverse effects on the use environment, and achieve improved flexibility, improved coating performance, and weight solid content Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

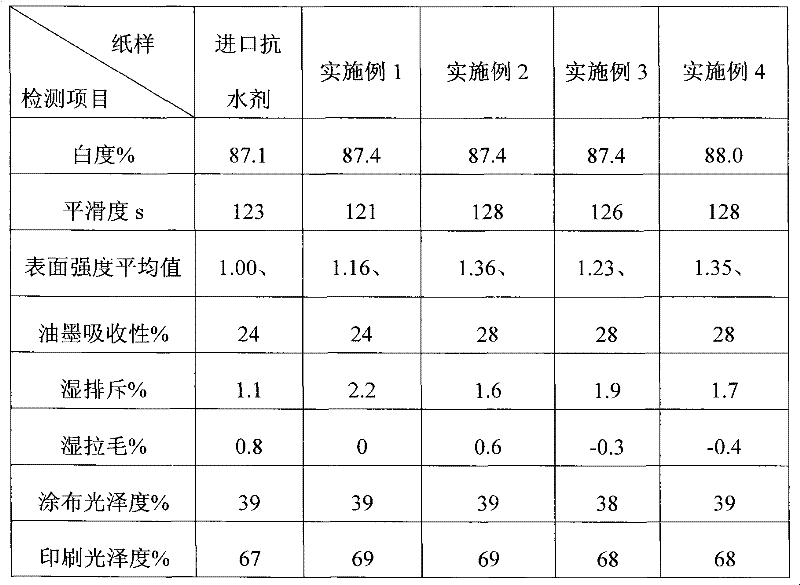

Examples

Embodiment 1

[0020] Add 93 grams of diethylenetriamine and 11 grams of diethanolamine in a 1-liter four-neck flask equipped with a condenser, a thermometer and agitation, and when stirring, add 9.27 grams of sulfuric acid solution with a weight concentration of 10%, stir, Add 118 grams of succinic acid within 1 hour, react at 120°C for 30 minutes, heat up to 160°C for 4 hours, and continuously separate the water generated in the system during the reaction, and then cool down to 140°C, add deionized 186 grams of water was used to obtain an intermediate with a solid content of 50%. When the temperature of the system dropped to 80°C, 94 grams of thiourea was added, the temperature was raised to 100°C for 12 hours, and 250 grams of deionized water was added. When the temperature of the system drops to 40°C, add 46.4 grams of epichlorohydrin, react at 40°C for 6 hours, adjust the pH of the solution to 6.0 with sulfuric acid with a weight concentration of 10%, and obtain a modified polyamide with...

Embodiment 2

[0022] Add 88 grams of diethylenetriamine and 16 grams of diethanolamine in a 1-liter four-necked flask equipped with a condenser, a thermometer and agitation. Under the situation of stirring, add 37 grams of sulfuric acid solution with a weight concentration of 10%, stir, Add 146 grams of adipic acid within 1.5 hours, react at 125°C for 40 minutes, heat up to 170°C for 3 hours, and then cool down to 140°C, add 214 grams of deionized water to obtain a weight solid content of 50%. For the intermediate, when the system temperature drops to 80°C, 103 grams of thiourea is added, the temperature is raised to 105°C for 10 hours, and 244 grams of deionized water is added. When the temperature of the system drops to 40°C, add 37 grams of epichlorohydrin, react at 30°C for 8 hours, add acetic acid with a weight concentration of 15% to adjust the pH value of the solution to 7.0, and obtain a modified polyamide polyamide with a weight solid content of 57.5%. An aqueous solution of urea e...

Embodiment 3

[0024] Add 87 grams of diethylenetriamine and 22 grams of diethanolamine in a liter 1 four-necked flask equipped with a condenser, a thermometer and stirring, and add 60 grams of 10% acetic acid while stirring, and stir within 0.5 hours Add 146 grams of adipic acid, react at 125°C for 40 minutes, then raise the temperature to 175°C and react for 2.5 hours. During the reaction, the reaction water in the system is continuously separated, and then when the temperature is lowered to 140°C, add 219 grams of deionized water. To obtain an intermediate with a weight solid content of 50%, when the system temperature dropped to 80°C, 118 grams of thiourea was added, the temperature was raised to 110°C for 6 hours, and 233 grams of deionized water was added. When the temperature of the system drops to 40°C, add 25 grams of epichlorohydrin, react at 30°C for 9 hours, add acetic acid with a weight concentration of 15% to adjust the pH value of the solution to 7.5, and obtain a modified poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com