Anti-yellowing stable DTY textile oiling agent and preparation method thereof

A textile oil, stable technology, applied in the field of DTY oil, can solve the problems of DTY textile oil development and improvement limitations, slow yellowing of products, yellowing, etc., to improve anti-yellowing performance, maintain its own stability, inhibit The effect of oil yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

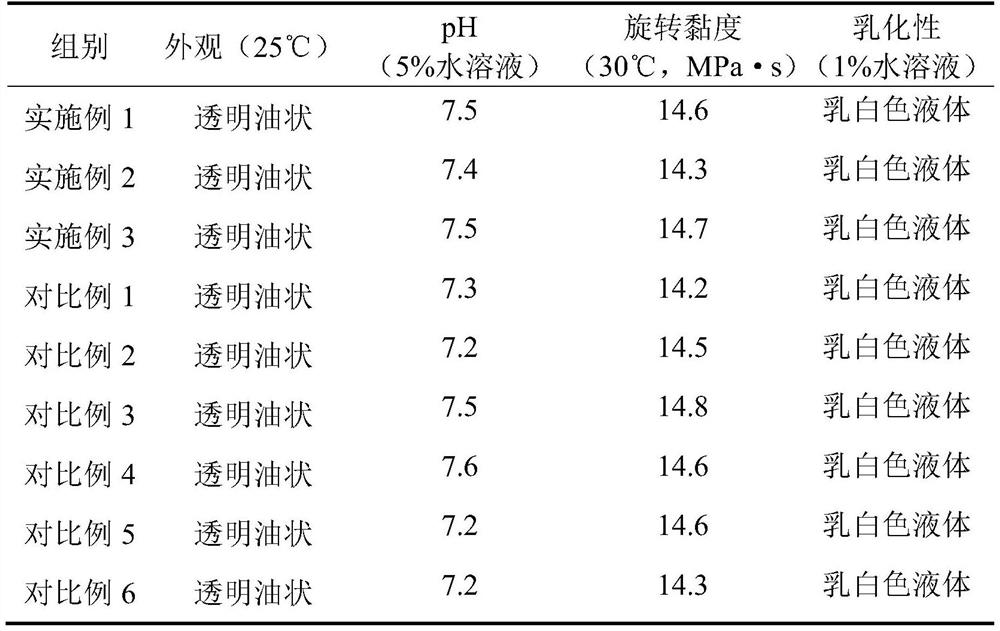

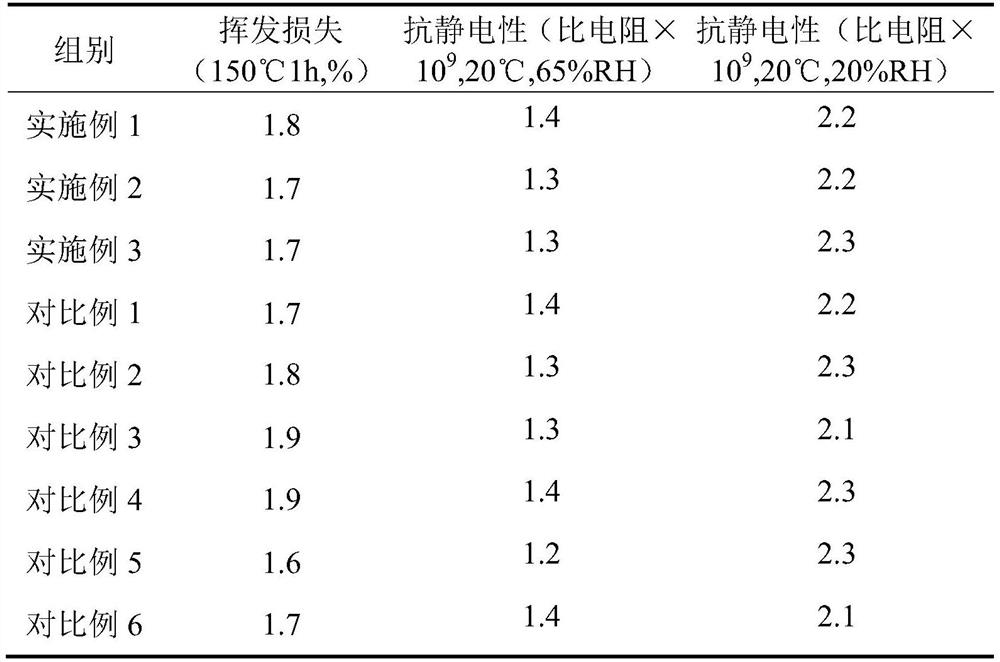

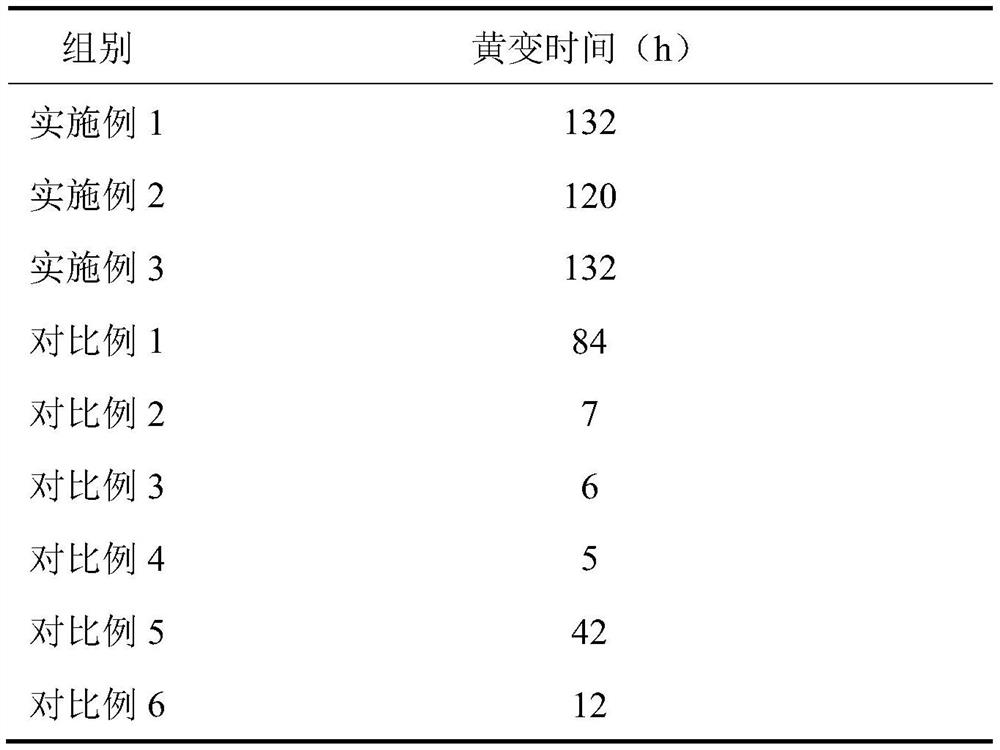

Examples

Embodiment 1

[0022] An anti-yellowing stable DTY textile oil, comprising the following components:

[0023] Industrial white oil 1000 parts

[0024] Polyoxyethylene (20) sorbitan monooleate 18 parts

[0025] Sorbic acid monostearate 7 parts

[0026] 3 parts D-phenylalanine

[0027] 1-fluoro-6-isopropylquinoline iodide salt 2 parts

[0028] Antistatic agent 7 parts

[0029] Anti-splash agent 7 parts

[0030] Penetrant 3 parts.

[0031] In this embodiment, the viscosity (30° C.) of the industrial white oil is in the range of 13.5-15.5 MPa·s. The antistatic agent uses lauryl amidopropyl trimethylamine, the anti-splash agent uses polyvinylpyrrolidone, and the penetrating agent uses simethicone.

[0032] The preparation method of the DTY textile oil agent of the present embodiment is as follows. Prepare according to the amount of each component; first heat the industrial white oil to 60°C, then take 100 parts of industrial white oil and 10 parts of polyoxyethylene (20) sorbitan monoolea...

Embodiment 2

[0034] An anti-yellowing stable DTY textile oil, comprising the following components:

[0035] Industrial white oil 1000 parts

[0036] Polyoxyethylene (20) sorbitan monooleate 15 parts

[0037] Sorbic acid monostearate 6 parts

[0038] 3 parts D-phenylalanine

[0039] 1 part of 1-fluoro-6-isopropylquinoline iodide salt

[0040] Antistatic agent 5 parts

[0041] Anti-splash agent 4 parts

[0042] Penetrant 3 parts.

[0043] In this embodiment, the viscosity (30° C.) of the industrial white oil is in the range of 13.5-15.5 MPa·s. The antistatic agent uses lauryl amidopropyl trimethylamine, the anti-splash agent uses polyvinylpyrrolidone, and the penetrating agent uses simethicone.

[0044] The preparation method of the DTY textile oil agent of the present embodiment is as follows. Prepare according to the amount of each component; first heat the industrial white oil to 50°C, then take 100 parts of industrial white oil and 10 parts of polyoxyethylene (20) sorbitan monool...

Embodiment 3

[0046] An anti-yellowing stable DTY textile oil, comprising the following components:

[0047] Industrial white oil 1000 parts

[0048] Polyoxyethylene (20) sorbitan monooleate 20 parts

[0049] Sorbic acid monostearate 10 parts

[0050] D-phenylalanine 5 parts

[0051] 1-fluoro-6-isopropylquinoline iodide salt 3 parts

[0052] Antistatic agent 8 parts

[0053] Anti-splash agent 10 parts

[0054] Penetrant 5 parts.

[0055] In this embodiment, the viscosity (30° C.) of the industrial white oil is in the range of 13.5-15.5 MPa·s. The antistatic agent uses lauryl amidopropyl trimethylamine, the anti-splash agent uses polyvinylpyrrolidone, and the penetrating agent uses simethicone.

[0056] The preparation method of the DTY textile oil agent of the present embodiment is as follows. Prepare according to the amount of each component; first heat the industrial white oil to 65°C, then take 100 parts of industrial white oil and 10 parts of polyoxyethylene (20) sorbitan monool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com