Bacteria preparation for processing waste with high lignin content

A bacterial preparation and preparation technology, applied in the field of microorganisms, can solve the problems of reducing the quality of cellulose and hemicellulose, consuming chemical reagents, polluting the environment, etc., achieving broad application prospects and improving the effect of composting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

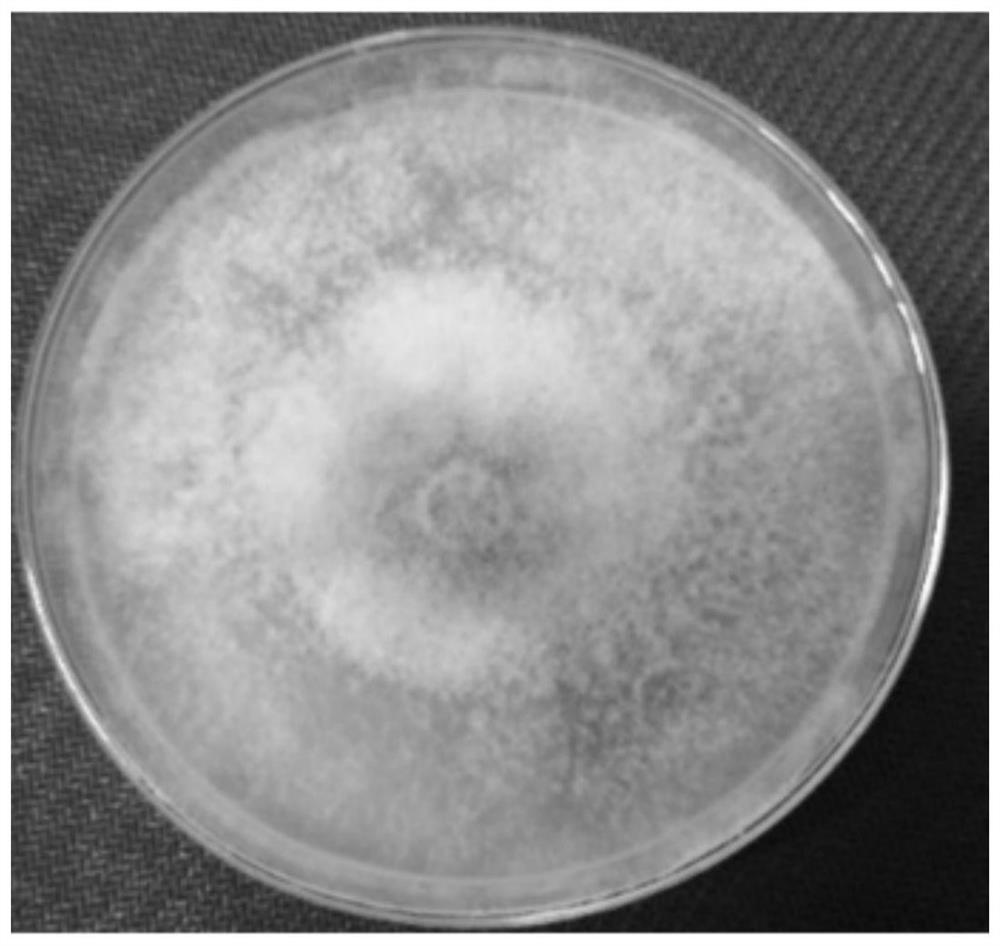

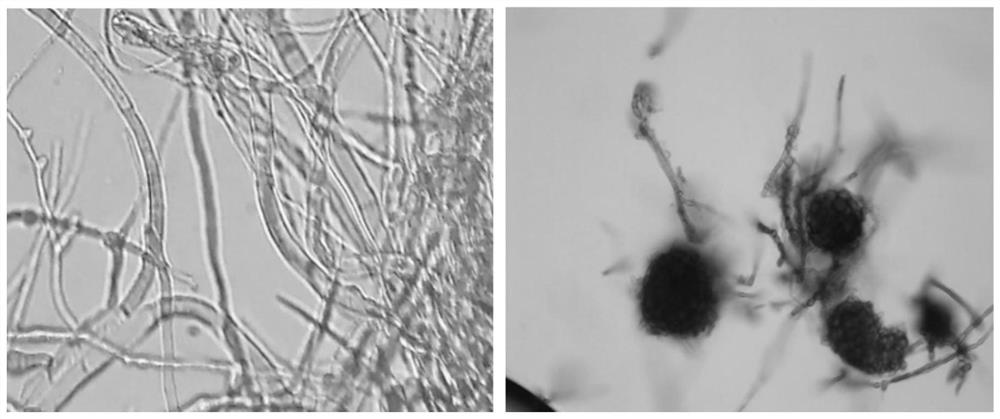

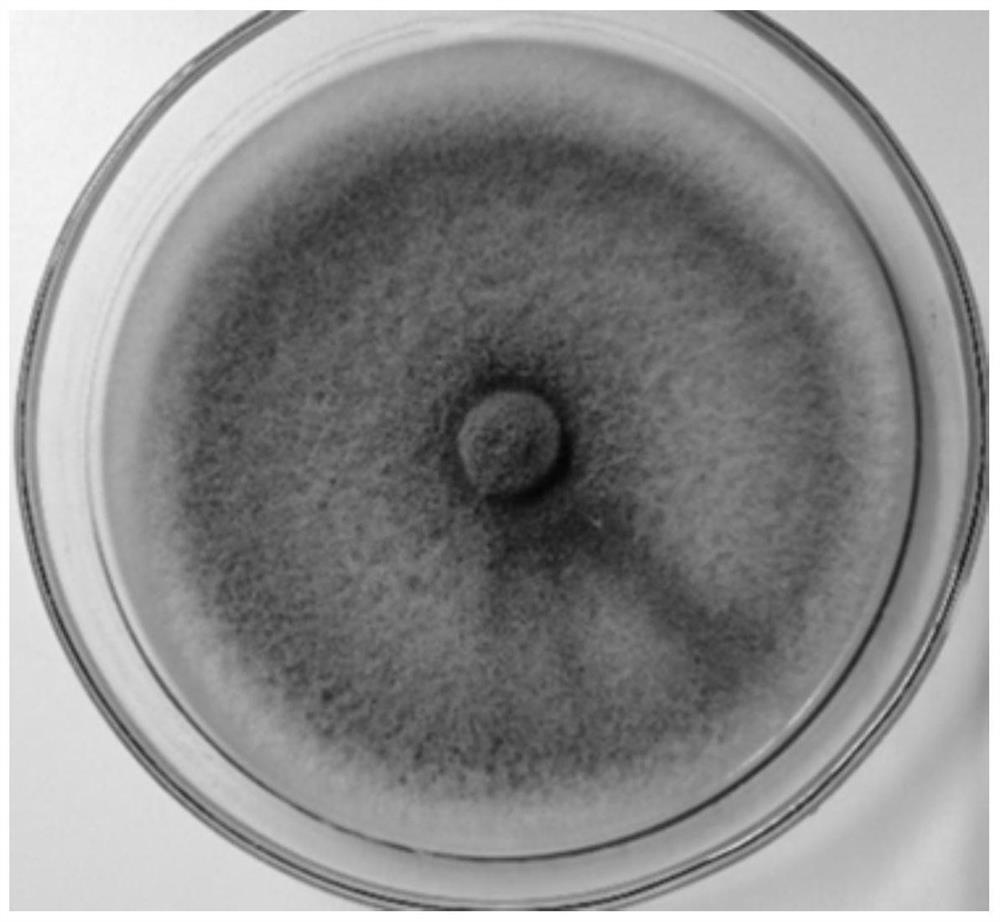

[0047] Example 1: Screening and identification of lignin-degrading bacteria

[0048] 1. Configuration of culture medium

[0049] (1) Alkali lignin medium: Alkali lignin 1.0g, NH 4 Cl 2.0g, K 2 HPO 4 1.0g, KH 2 PO 4 1.0g, MgSO 4 ·7H 2 O 0.20g, CaCl2 0.1g, FeSO 4 ·7H 2 O 0.05g, MnSO 4 ·7H 2 O 0.02g, add agar 15.0g, make up water to 1000mL. Sterilize at 121°C for 20 minutes. The corresponding liquid culture medium does not need to add agar.

[0050] (2) Potato medium (PDA): 200g of peeled potatoes, cut into pieces and boiled, filtered with gauze, added 20.0g of glucose to the filtrate, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 1.5g, add agar 15.0g, make up water to 1000mL. Sterilize at 115°C for 30 minutes. The corresponding liquid culture medium does not need to add agar.

[0051] 2. Isolation and purification of strains

[0052] The composting plant corn stalk samples were inoculated on the alkali lignin solid medium under sterile conditions, and cultured at 30°C f...

Embodiment 2

[0065] Example 2: Optimization of conditions for degrading alkali lignin by lignin-degrading bacteria

[0066] Take the strains activated on the PDA slant for 24 hours, inoculate MSDA1 and HDGA2 in 100mL / 250mL Erlenmeyer flasks at 2% inoculum, and cultivate them at 30°C and 150r for 24 hours to prepare seed liquid. In the seed liquid, the concentration of viable bacteria of each microorganism ≥10 8 CFU / mL. Then the seed solution of each microorganism was inoculated into 50mL liquid alkali lignin medium according to the inoculation ratio of 10% by volume, and the single factor test was used to investigate different time, different nitrogen sources, different rotation speeds, different alkali lignin concentrations, etc. Effects on MSDA1 and HDGA2 degradation of alkali lignin. In addition to the investigated factors, the culture conditions are: pH=6.5, 30°C, 150r / min shaker culture for 5 days. details as follows:

[0067] 1. The effect of different time on the degradation rat...

Embodiment 3

[0084] Example 3: Validation of the effect of lignin-degrading bacteria on degrading lignin in sawdust

[0085] After drying the sawdust at 105°C, pass through a 40-mesh sieve, and then separate the PDA seed liquids of the fecal shell fungus MSDA1 and the hyphosporium HDGA2 (each viable bacteria concentration ≥ 10 8 CFU / mL) was inoculated into sawdust at an inoculum volume of 1 mL / g. After mixing thoroughly, the culture temperature was 30° C., and the culture was statically cultivated for 10 days. Inoculate MSDA1 directly into wood chips as group 1; add 3.4g / kg ammonium tartrate, and other conditions are the same as group 1, as group 2; directly inoculate HDGA2 into wood chips as group 3; add 1.5g / L ammonium nitrate, Other conditions are the same as group 3, as group 4. Determination of weight loss rate, degradation rate of lignin and cellulose (paradigm method) and selectivity coefficient. Selectivity coefficient = lignin degradation rate / cellulose degradation rate. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com