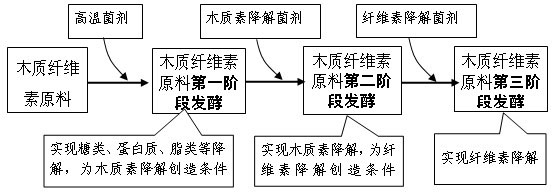

Three-stage inoculation process and microbial agents for composting lignocelluloses raw material

A technology of lignocellulose and microbial inoculants, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, and organic fertilizers, can solve problems such as removal or destruction, improve efficiency, shorten composting time, and expand large-scale applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 The preparation of microbial inoculants used in three-stage composting, the specific steps are as follows:

[0020] (1) Preparation of high temperature bacteria

[0021] Using cow dung extract as the medium and 55°C culture conditions as the screening conditions, two thermophilic microorganisms that can grow normally on the cow dung extract medium under 55°C culture conditions were isolated from cow dung: Thermoactinomyces sp GF1 and Thermoactinomyces sp GF2.

[0022] The preparation of bacterial agents is divided into two stages. Specifically:

[0023] The first stage is fermentation. Inoculate the two strains on a plate containing PDA medium and place them in an incubator at 55°C for 5-7 days. After the two strains grow on the plate and produce spores, the spores are eluted and collected with sterile water. , Obtain the spore suspensions of the two strains respectively. The spore suspension of the two strains was centrifuged by a high-speed centrifuge at a c...

Embodiment 2

[0029] Example 2 Three-stage inoculation process of cow dung and straw compost

[0030] (1) Pretreatment of cow dung and straw

[0031] According to the research results of the optimized combination of high-temperature inoculants and culture conditions, the C / N ratio of the mixture of cow manure and straw was adjusted to 27, the moisture content was 75%, and the pH was 7.5.

[0032] (2) Preparation of microbial agents: the preparation method is as in Example 1.

[0033] (3) Stacking of raw materials, this stage is divided into the following three steps

[0034] In the first step, 360 ml of high-temperature inoculants are thoroughly mixed with 36.4 kg of cow dung and straw mixture, and the inoculum concentration reaches 1×10 per gram of piled material. 8 Pile up the mixed cow dung and straw, and monitor the temperature of the pile from the second day of stacking. The temperature of the stack reached 47°C on the second day, and reached the highest temperature of 68°C on the fourth day. ...

Embodiment 3

[0038] Example 3 Three-stage inoculation process of pig manure and straw compost

[0039] (1) Pretreatment of straw

[0040] According to the research results of the optimized combination of high-temperature inoculants and culture conditions, the C / N ratio of the straw mixture was adjusted to 25, the moisture content was 65%, and the pH was 6.

[0041] (2) Preparation of microbial agents: the preparation method is as in Example 1.

[0042] (3) Stacking of raw materials, this stage is divided into the following three steps

[0043] In the first step, 470 ml of high-temperature inoculum is thoroughly mixed with 47 kg of pig manure and straw mixture, and the inoculum concentration reaches 1×10 per gram of stock 8 Stack the mixed pig manure and straw, and monitor the temperature of the pile from the second day of stacking. The temperature of the stack reached 50°C on the second day and the maximum temperature of 73°C on the third day. The temperature of the stack was maintained at a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com