High-temperature oxidation resistant low-viscosity synthetic ester as well as preparation method and application thereof

A high-temperature oxidation-resistant and ester-synthesizing technology, used in lubricating compositions, base materials, petroleum industry, etc., can solve problems such as being unsuitable for air compressor oil and heat-conducting oil systems, the inability of degradants to be effectively dispersed, and high-temperature oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

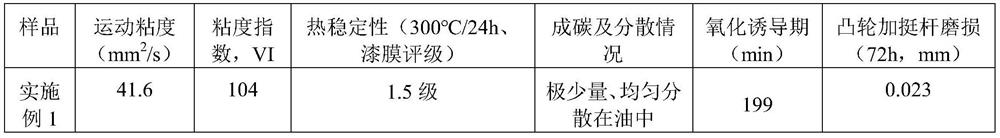

Examples

Embodiment 1

[0027] The high-temperature oxidation-resistant low-viscosity synthetic ester described in this embodiment, the raw materials for its preparation include the following components:

[0028] Trimethylolpropane 15mol;

[0029] Neopentyl glycol 10mol;

[0030] Succinic acid 12mol;

[0031] 1,4-cyclohexanedicarboxylic acid 4mol;

[0032] 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid 4mol;

[0033] Triethylchlorosilane 15mol;

[0034] Tripropylchlorosilane 32mol;

[0035] Xylene 20mol;

[0036] Monobutyltin oxide 0.02mol;

[0037] Anhydrous sodium carbonate 16.5mol.

[0038] The preparation method of the high-temperature oxidation-resistant low-viscosity synthetic ester described in this embodiment comprises the following steps:

[0039] (1) Take the described trimethylolpropane, neopentyl glycol, succinic acid, 1,4-cyclohexanedicarboxylic acid, 3-(3,5-di-tert-butyl-4-hydroxy Phenyl)propionic acid, monobutyl tin oxide catalyst, and xylene are added to the reaction ket...

Embodiment 2

[0044] The high-temperature oxidation-resistant low-viscosity synthetic ester described in this embodiment, the raw materials for its preparation include the following components:

[0045] Trimethylolpropane 25mol;

[0046] Neopentyl glycol 5mol;

[0047] Succinic acid 9mol;

[0048] 1,4-cyclohexanedicarboxylic acid 6mol;

[0049] 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid 6mol;

[0050] Triethylchlorosilane 25mol;

[0051] Tripropylchlorosilane 44mol;

[0052] Xylene 30mol;

[0053] Monobutyltin oxide 0.06mol;

[0054] Anhydrous sodium carbonate 25mol.

[0055] The preparation method of the high-temperature oxidation-resistant low-viscosity synthetic ester described in this embodiment comprises the following steps:

[0056] (1) Take the described trimethylolpropane, neopentyl glycol, succinic acid, 1,4-cyclohexanedicarboxylic acid, 3-(3,5-di-tert-butyl-4-hydroxy Phenyl)propionic acid, monobutyl tin oxide catalyst, and xylene are added to the reaction kettle, m...

Embodiment 3

[0061] The high-temperature oxidation-resistant low-viscosity synthetic ester described in this embodiment, the raw materials for its preparation include the following components:

[0062] Trimethylolpropane 20mol;

[0063] Neopentyl glycol 8mol;

[0064] Succinic acid 7mol;

[0065] 1,4-cyclohexanedicarboxylic acid 8mol;

[0066] 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid 3mol;

[0067] Triethylchlorosilane 22mol;

[0068] Tripropylchlorosilane 39mol;

[0069] Xylene 25mol;

[0070] Monobutyltin oxide 0.06mol;

[0071] Anhydrous sodium carbonate 22mol.

[0072] The preparation method of the high-temperature oxidation-resistant low-viscosity synthetic ester described in this embodiment comprises the following steps:

[0073] (1) Take the described trimethylolpropane, neopentyl glycol, succinic acid, 1,4-cyclohexanedicarboxylic acid, 3-(3,5-di-tert-butyl-4-hydroxy Phenyl)propionic acid, monobutyl tin oxide catalyst, and xylene are added to the reaction kettle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com