Composite material based on lignocellulose and bacterial cellulose as well as preparation method and application of composite material

A technology of bacterial cellulose and lignocellulose, applied in shielding materials, chemical instruments and methods, other chemical processes, etc., can solve the problems of poor corrosion resistance and high density of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

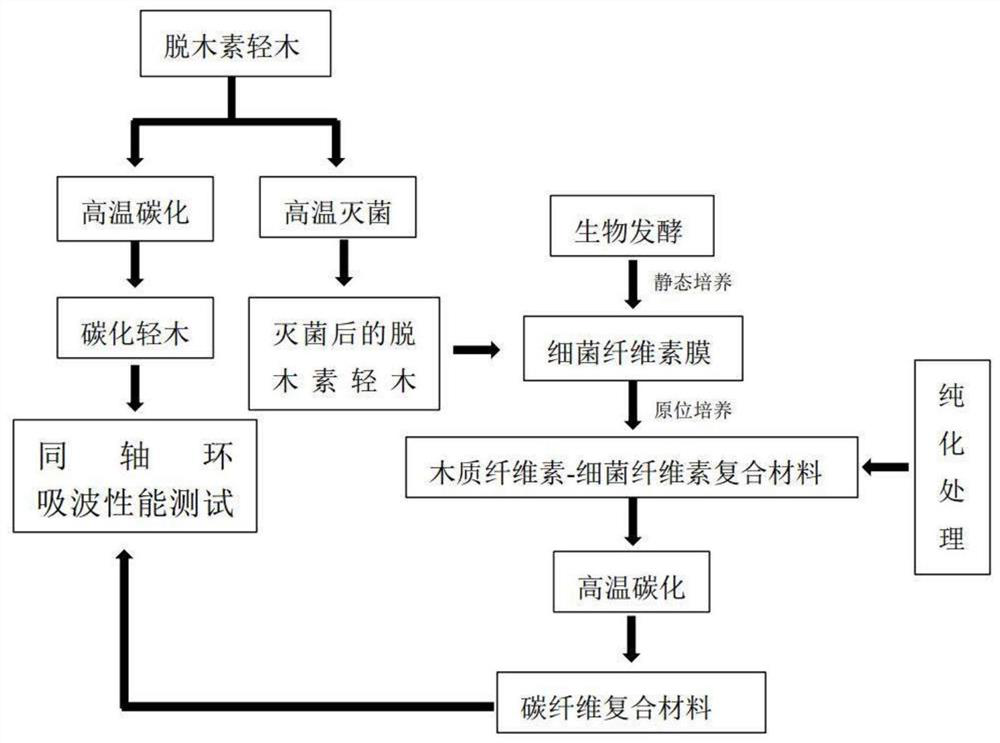

Method used

Image

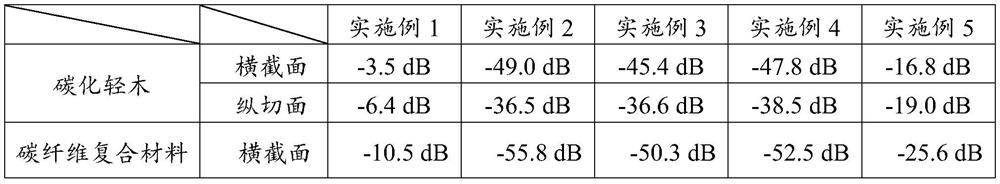

Examples

Embodiment 1

[0029] The preparation method of the composite material based on lignocellulose and bacterial cellulose, the specific steps are as follows:

[0030] 1) Add 0.5mol sodium chlorite and 20mL glacial acetic acid to 1000mL deionized water to obtain a mixed solution, pour it into a container of balsa wood (60*60*2mm 3 ) reaction tank, heated to boiling, and kept warm for 3 hours, during which the mixed solution was replaced 4 times; cooled, washed repeatedly with ethanol and deionized water, and freeze-dried to obtain delignified balsa wood chips; the vacuum degree of the freeze dryer was less than 10Pa, and the cold trap The temperature is lower than -80°C, and the drying time is longer than 24 hours; the cross-sectional direction of the balsa wood chips is the cross-section;

[0031] 2) Sterilize the delignified balsa wood chips in an autoclave to obtain sterilized delignified balsa wood chips; the sterilization temperature is 121° C., the time is 20 minutes, and the pressure is l...

Embodiment 2

[0041] The preparation method of the composite material based on lignocellulose and bacterial cellulose, the specific steps are as follows:

[0042] 1) Add 0.5mol sodium chlorite and 20mL glacial acetic acid to 1000mL deionized water to obtain a mixed solution, pour it into a container of balsa wood (60*60*2mm 3 ) reaction tank, heated to boiling, and kept warm for 3 hours, during which the mixed solution was replaced 4 times; cooled, washed repeatedly with ethanol and deionized water, and freeze-dried to obtain delignified balsa wood chips; the vacuum degree of the freeze dryer was less than 10Pa, and the cold trap The temperature is lower than -80°C, and the drying time is longer than 24 hours; the cross-sectional direction of the balsa wood chips is the cross-section;

[0043] 2) Sterilize the delignified balsa wood chips in an autoclave to obtain sterilized delignified balsa wood chips; the sterilization temperature is 121° C., the time is 20 minutes, and the pressure is l...

Embodiment 3

[0053] The preparation method of the composite material based on lignocellulose and bacterial cellulose, the specific steps are as follows:

[0054] 1) Add 0.5mol sodium chlorite and 20mL glacial acetic acid to 1000mL deionized water to obtain a mixed solution, pour it into a container of balsa wood (60*60*2mm 3 ) reaction tank, heated to boiling, and kept warm for 3 hours, during which the mixed solution was replaced 4 times; cooled, washed repeatedly with ethanol and deionized water, and freeze-dried to obtain delignified balsa wood chips; the vacuum degree of the freeze dryer was less than 10Pa, and the cold trap The temperature is lower than -80°C, and the drying time is longer than 24 hours; the cross-sectional direction of the balsa wood chips is the cross-section;

[0055] 2) Sterilize the delignified balsa wood chips in an autoclave to obtain sterilized delignified balsa wood chips; the sterilization temperature is 121° C., the time is 20 minutes, and the pressure is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com