Yellow phosphorus preparation process based on oxygen thermal method

A preparation process, oxygen-thermal method, applied in sustainable manufacturing/processing, chemical industry, phosphorus compounds, etc., can solve the problems of low gas output, difficult chemical raw materials, and high production cost of yellow phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

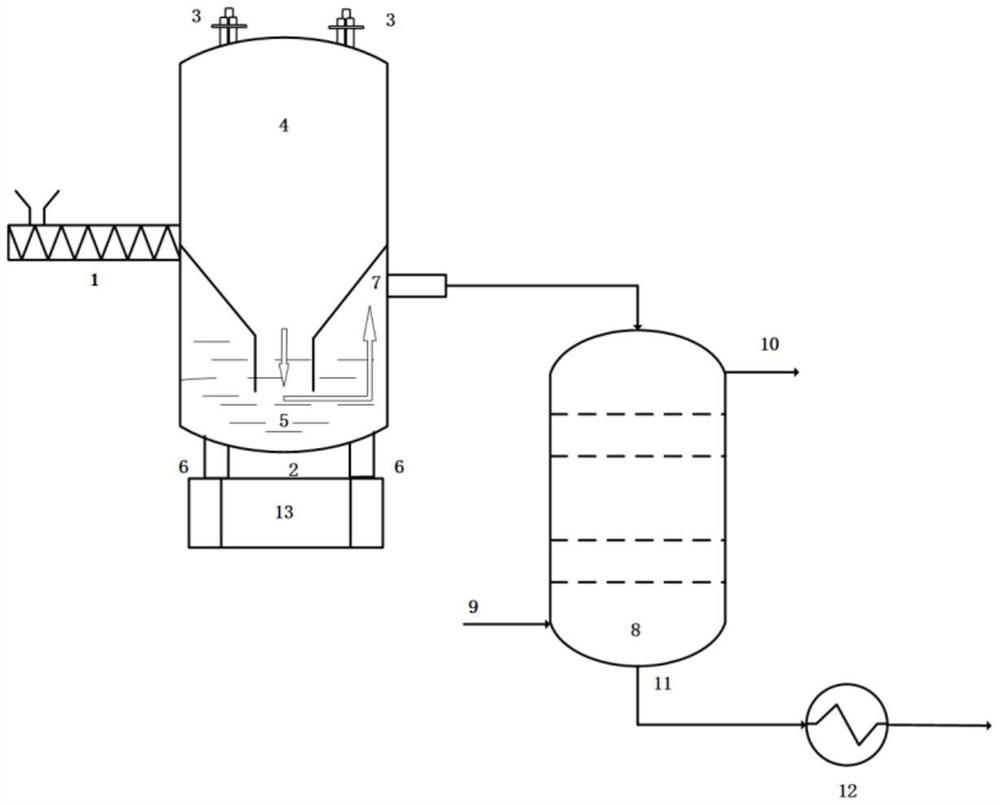

[0023] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0024] The process and method for preparing yellow phosphorus based on oxythermal method in the present invention, the main equipment and devices include: entrained bed reactor 2, slagging waste heat recovery device 13, cylinder with water wall 8 and phosphate rock / silica waste heat device 12.

[0025] The top of the entrained bed reactor is provided with a feed nozzle 3, the middle and lower part of the furnace is provided with a phosphate rock feeder 1, the middle and lower part of the furnace is provided with a synthesis gas outlet 7, and the bottom of the furnace is provided with a slagging outlet 6, and the inside of the furnace is And the bottom is divided into gasification reaction zone 10 and molten pool reaction zone 11. The syngas outlet 7 is connected to a cylinder with a water-cooled wall 8, and the cylinder is provided with a feedwater inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com