Grinding adjusting device for preventing grinding wheel from shaking

A technology for adjusting the device and grinding wheel, which is applied to the device for fixing the grinding wheel, the parts of the grinding machine tool, and the grinding/polishing equipment, etc. It can solve the problems of reducing economic benefits, increasing the scrap rate, and long running time of the grinding wheel, and avoiding the precision Low, ensure production quality, avoid life-threatening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

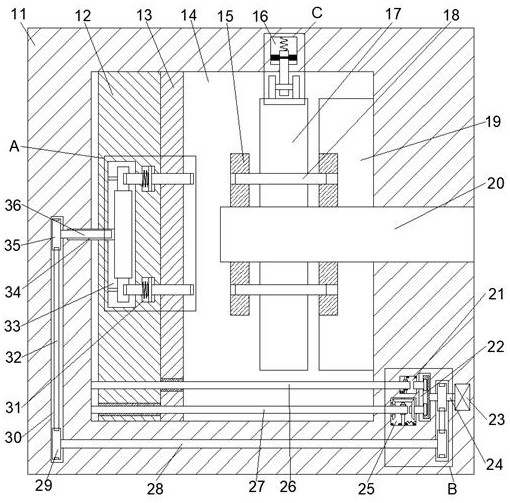

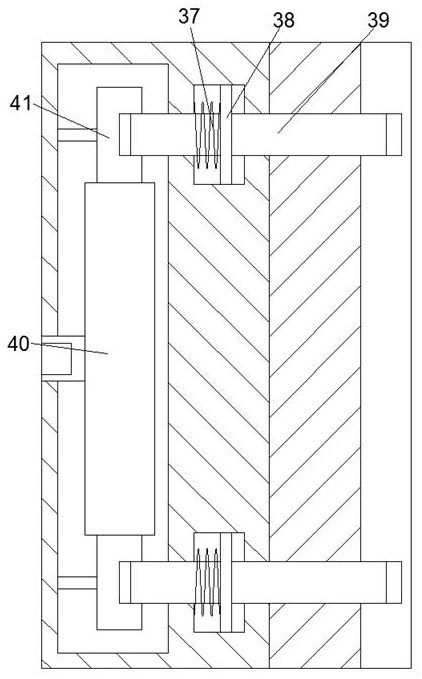

[0015] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] A grinding adjustment device for preventing the shaking of the grinding wheel according to the present invention includes a box body 11, the box body 11 is provided with a working chamber 14 with an opening facing backward, and a working device is arranged in the working chamber 14, and the working chamber 14 is provided with a working device. A detection chamber 16 is provided on the upper side of the chamber 14, a detection device is arranged in the detection chamber 16, a synchronous chamber 30 is provided on the left side of the working chamber 14, and a compression switching chamber 21 is provided on the right side of the working chamber 14, so The lower side of the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com