Adjustable bending device for aluminum alloy profile machining

An aluminum alloy profile and bending device technology, applied in metal processing equipment, forming tools, stripping devices, etc., can solve problems such as increased costs, hidden dangers to operator life safety, inflexibility, etc., and achieves excellent thermal conductivity and optimized plasticity. , to ensure the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

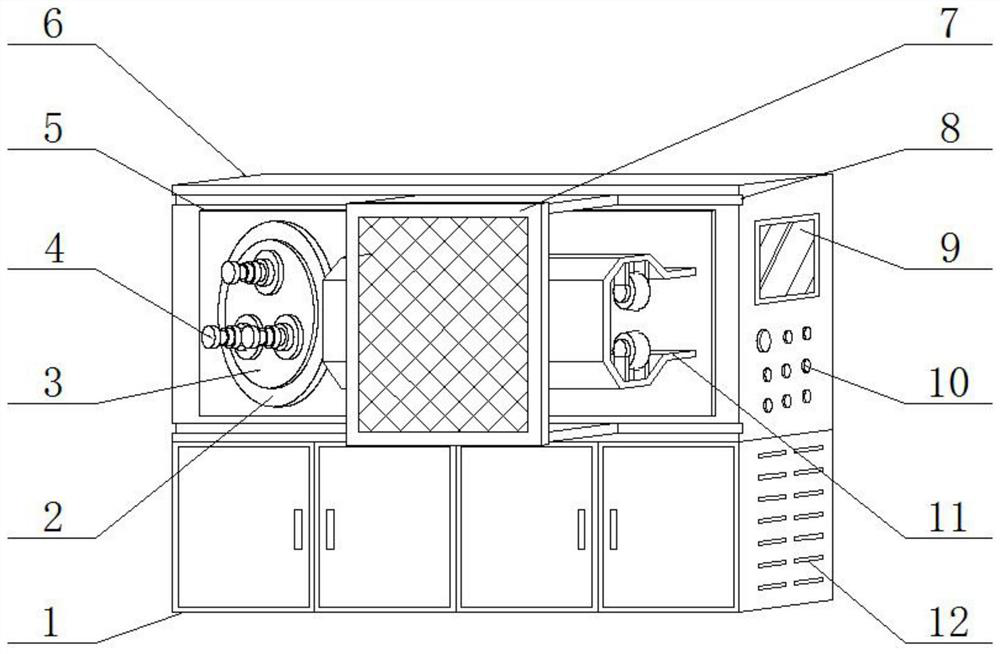

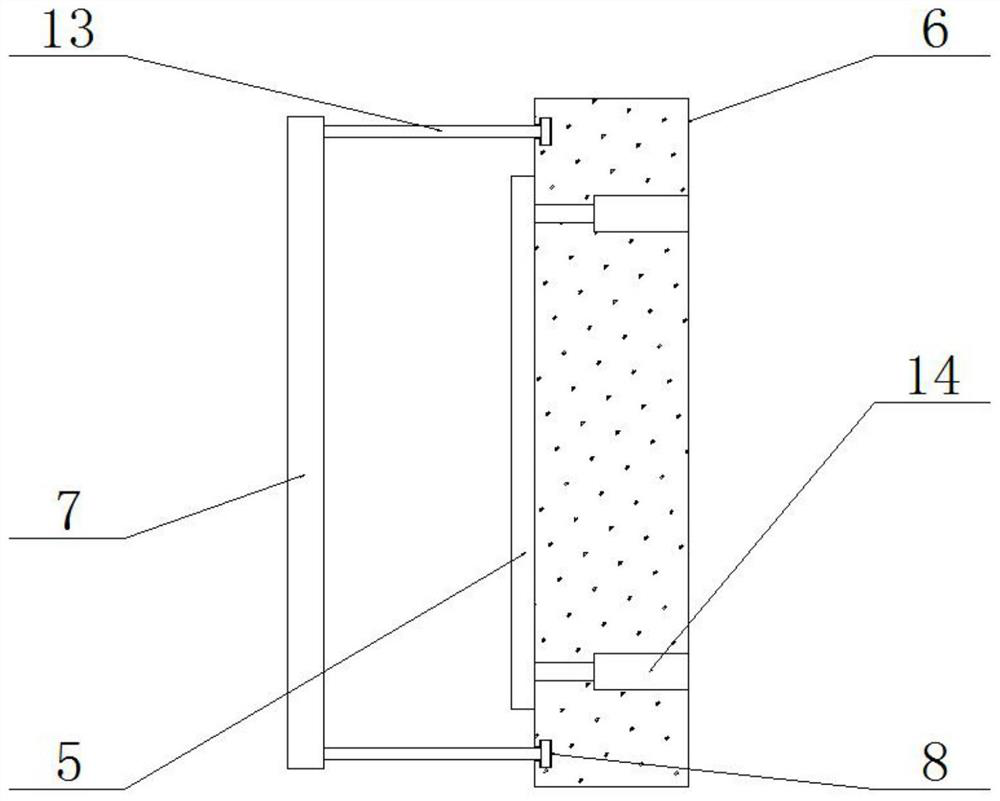

[0029]Embodiment 1. An adjustable bending device for processing aluminum alloy profiles, including an upper casing 6, a lower casing 1 is fixedly installed on the lower end of the upper casing 6, and a cooling hole is opened on the right side of the lower casing 1 12. The front end of the upper housing 6 is fixedly installed with a first movable plate 5, and a chute 8 is opened above the first movable plate 5, and a protective net 7 is fixedly installed at the front end of the first movable plate 5. On the first movable plate 5 The heating and transmission device 11 is fixedly installed, the left end of the heating and transmission device 11 is fixedly installed with a fixed disk 2, the fixed disk 2 is fixedly installed with a turntable 3, the turntable 3 is fixedly installed with a bending device 4, and the right end of the upper casing 6 A display screen 9 is fixedly installed, a control panel 10 is fixedly installed below the display screen 9, a first connecting rod 13 is fi...

Embodiment 2

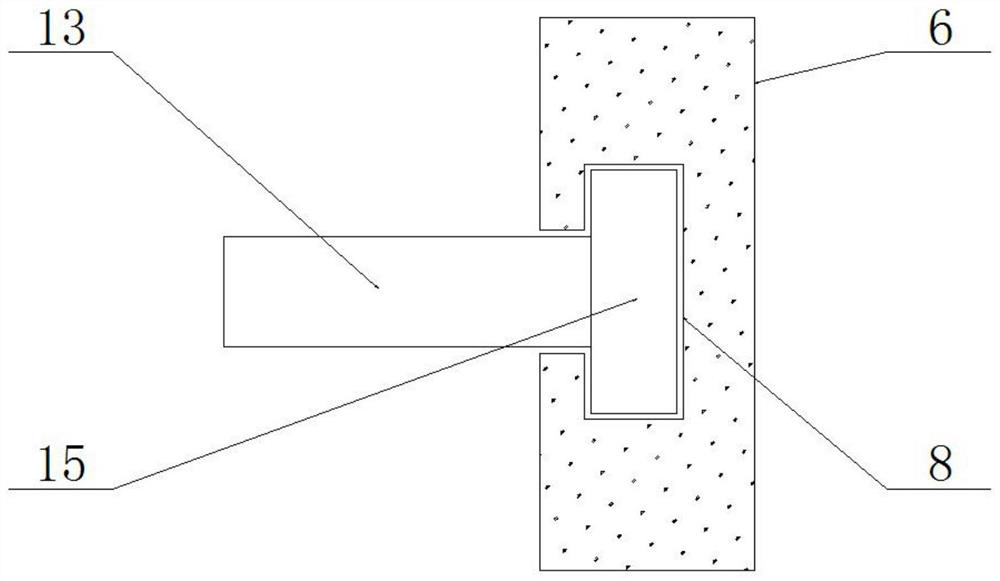

[0031] Embodiment 2. There are several groups of first connecting rods 13, and several groups of first connecting rods 13 are symmetrically distributed on the upper and lower ends of the protective net 7. A group of pulleys 15 are fixedly installed at the ends of several groups of first connecting rods 13. There are two groups of chute 8, and the two groups of chute 8 are set on the upper and lower sides of the first movable plate 5 respectively. The mutual cooperation activity connection.

[0032] In this embodiment, the protective net 7 can protect the operator, avoiding the misalignment of the profile during the bending process and causing damage to the operator caused by ejection. At the same time, the protective net 7 is installed in a movable manner, which is very convenient to move , will not affect the disassembly and replacement of the bending device 4 and the later maintenance.

Embodiment 3

[0033] Embodiment 3, the outermost side of the heating and transmission device 11 is provided with an outer casing 25, the outer casing 25 and the first movable plate 5 are welded and fixed, and the inside of the outer casing 25 is provided with a heating structure and a transmission structure 28, and the heating structure is composed of an expanded perlite layer. 26 and the heating layer 27, the heating layer 27 is provided with a coil inside, and the material of the inner shell 29 is copper; the transmission structure 28 is composed of several sets of runners 30, and each set of runners 30 is provided with two sets of third connecting rods 31, the runner 30 and the third connecting rod 31 are flexibly connected by a connecting piece, and a group of springs 32 are fixedly installed inside each group of third connecting rods 31, and the spring 32 is fixedly connected with the connecting piece, and the surface of the runner 30 is Concave.

[0034] In this embodiment, the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com